|

Re: Pinion seal

|

||||

|---|---|---|---|---|

|

Home away from home

|

I found this on another thread from last month:

Yes, the precision length crush sleeve sets the preload for the pinion shaft bearings. Count exactly the number of turns to remove the nut and install it exactly the same number of turns, no more - no less). Carefully mark the nut and the housing to establish installed position.

Posted on: 2012/10/5 6:06

|

|||

|

[color=0099FF]Respectfully,

|

||||

|

||||

|

Re: Pinion seal

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

There really are two issues here, the continuing leak and the pinion bearing preload. They may or may not be related.

With regard to the bearing preload, if you're not installing a new crush sleeve then the only option, as noted above, is to tighten the pinion retainer nut to exactly the same position as it was in when removed. Of course this assumes that it was properly set in the first place - if a previous attempt to repair did not reestablish the preload, then whatever position it is in is useless information and you'll have to go back to basics and reestablish the preload from scratch. Though the pinion seal is the most likely source of a leak, it isn't the only possibility so clean things up and take a good look at the carrier to housing area. Also make sure the rear axle housing vent is clear - this is usually at the bolt head on the hydraulic fitting block. If you find the leak is still at the pinion seal and the vent was open, either the seal is incorrect, incorrectly installed, or the pinion shaft is scored or worn (which often can be sleeved).

Posted on: 2012/10/5 9:36

|

|||

|

||||

|

Re: Pinion seal

|

||||

|---|---|---|---|---|

|

Home away from home

|

Good suggestions from O_D, as usual. There may be one more thing to look at. The surface on the drive shaft flange may have a groove worn into it that will not let the new pinion seal prevent leakage. This can be easily fixed. Install a Redisleeve or Speedisleeve (names used by different manufactures, but basically the same thing). The sleeve goes over the worn surface and provides a new sealing surface. An easy fix for a worn sealing surface. A good bearing supply store should be able to find one that will work for you.

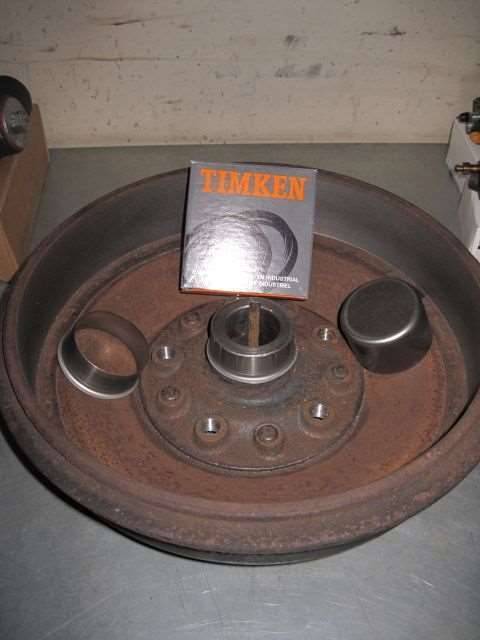

Here are two photos showing a sleeve I used on a worn surface where the outside rear axle seal had worn a groove in the brake drum sealing surface. I used a Timken sleeve, but National also makes them. I believe Timken and National are the same company, but continue to operate with their original names. The sleeves come with an installation tool. The sleeve I used was a bit long and I needed to trim it. Good luck. (o[]o)

Posted on: 2012/10/5 10:18

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: Pinion seal

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

A dumb question since I've never used the sleeves. Is the sleeve thin enough the lip of the regular called for seal expands and works with them or does it need a special larger ID seal?

Posted on: 2012/10/5 10:55

|

|||

|

Howard

|

||||

|

||||

|

Re: Pinion seal

|

||||

|---|---|---|---|---|

|

Home away from home

|

I think the real question is where is the leak coming from? You have to know that before you can fix it. Also which model of Packard are you talking about, because I know that the '47 had a Service Bulletin about leaks around the bolts that hold the differential together. So lets step back and take another look at the problem.

Wes

Posted on: 2012/10/5 12:10

|

|||

|

||||

|

Re: Pinion seal

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Howard, not a dumb question at all. The Timken sleeves that I used were made of a thin wall construction and used the standard seal. I believe this is the case with the National sleeve applications too. Mal took a nice photo of you. Nice to put a face with the words we read here. (o[]o)

Posted on: 2012/10/8 11:33

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

(28.96 KB)

(28.96 KB)