|

Oil filter piping for 1948 Packard 288 engine

|

||||

|---|---|---|---|---|

|

Home away from home

|

I need the correct piping diagram for 48 Packard 288 engine. I’ve seen several adaptions.

Thanks

Posted on: 2022/7/10 8:36

|

|||

|

||||

|

Re: Oil filter piping for 1948 Packard 288 engine

|

||||

|---|---|---|---|---|

|

Home away from home

|

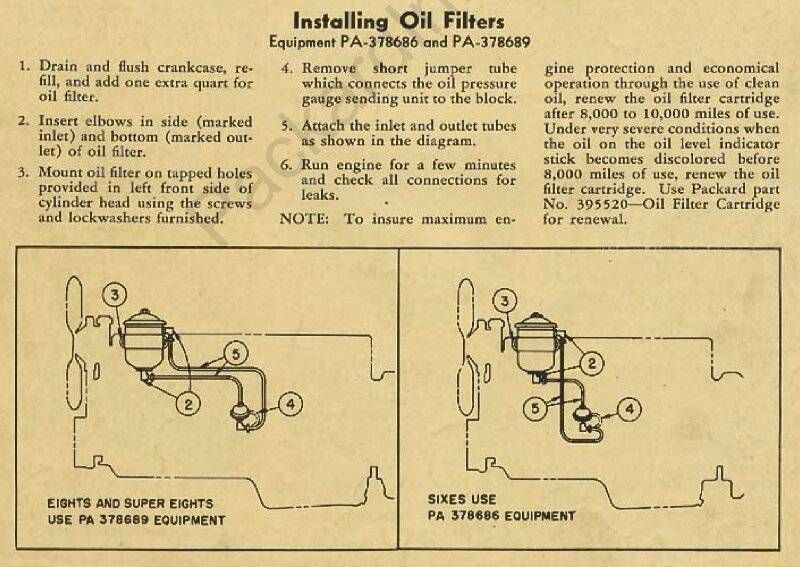

I do not understand the oil filter piping drawing in the bulletin.

Is the inlet connection on an elbow behind the sending unit? I see how the lower connection is.

Posted on: 2022/7/30 13:44

|

|||

|

||||

|

Re: Oil filter piping for 1948 Packard 288 engine

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The drawing is a bit odd but so is the fitting. On your engine there should be a brass tee like fitting between the sender and block. Referring to the drawing, the sender should be on the end of the tee while the short curved pigtail (4) feeding the upper lifter gallery port would be on the side of the tee.

To install the filter on your particular solid lifter engine the short pigtail (4) is removed. If you have or are making the new tubing in the form as shown in the diagram you don't need to do anything else. If the tubing is from a filter off a later engine, those have a slightly different arrangement and you might need to change the tee to a standard type so the side port can point to the front. The new tube to the filter inlet is connected back to the side port on the tee taking the place of the short pigtail. The new outlet tube from the filter is then connected back to the top port on the engine block the pigtail used to feed. All you are doing is replacing the short pigtail with the plumbing to and from the oil filter so lifter gallery oil supply flows thru the filter and then back to the upper port. The only time this plumbing route could be problematic on the pre 50 or 51 engines was if the engine had the optional hydraulic lifters installed. For the 356 hydraulic lifter engines and those 288/327 blocks made from 50 or 51 on it is a bit more involved. Early 356 engines with the revised plumbing where filtered oil returned directly back to the crankcase had two end to end tees but those were soon replaced by a special brass fitting that is just a square block with end and two side ports. One end port into the block, sender stayed on the other end port but oil to the lifters was thru the pigtail from the rear side port on the brass block and oil to the filter was from the front side port and then returned directly to the crankcase thru a new port cast low on the block just above the oil pan. The later engines had the square block replace the tee when a filter was added and block was used thru 54. Filter tubing connecting to the front port is shorter and the reason you might need to change the tee if that is the tubing you have. With the revised plumbing and square brass block, filters were all connected the same and it did not matter if the filter clogged or if the engine had hydraulic or solid lifters because the lifter gallery always got a full oil supply thru the pigtail.

Posted on: 2022/7/30 15:13

|

|||

|

Howard

|

||||

|

||||

|

Re: Oil filter piping for 1948 Packard 288 engine

|

||||

|---|---|---|---|---|

|

Home away from home

|

What size tubing is best for plumbing the filter?

Posted on: 2022/7/30 19:49

|

|||

|

||||

|

Re: Oil filter piping for 1948 Packard 288 engine

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

For these type filters Packard factory formed filter tubing was 1/4" steel and except for the custom 4 port brass block on the lower engine feed port, used mostly standard inverted flare fittings -- although the one between the sender and block which has the sender mounted vertically may be hard to find today. Later engines just used a standard tee with the sender horizontal. Prewar filter canisters with the revised plumbing did have one special elbow. A standard fitting was customized by having the passage filled and then a small orifice drilled to limit flow thru the filter.

Aftermarket filter installs by the gas station or corner garage were also common in the day and those often used copper or thin wall hydraulic hose so you might see that on a car too.

Posted on: 2022/7/30 20:05

|

|||

|

Howard

|

||||

|

||||

|

Re: Oil filter piping for 1948 Packard 288 engine

|

||||

|---|---|---|---|---|

|

Home away from home

|

Packwagon;

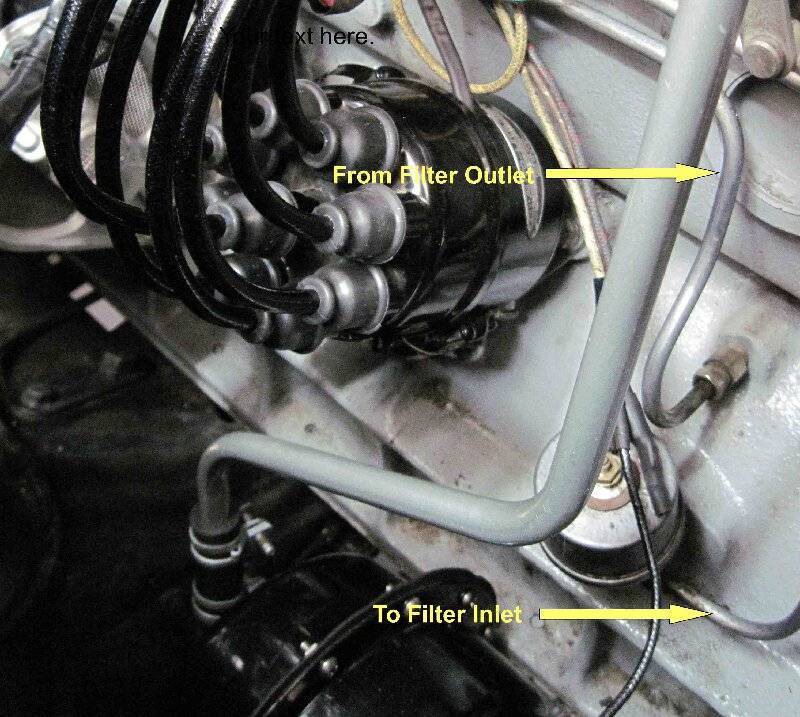

Packard used what I consider a unique lubrication schematic when it came to the tappet gallery. Unique because the oil destined for the tappets was routed external before being directed back into the block. Given that engines with hydraulic lifters benefited from filtered oil, the oil filter was plumbed ‘in series’ with this external circuit. Later the subject of poor lifter performance when the filter became restricted was resolved by plumbing the filter as a pure partial flow device where the discharge of the filter was routed directly to the oil pan area. All engines placed the oil pressure sending unit in the external tappet gallery plumbing. I believe there was some advice from Packard on how to convert an early engine block to the later design that routed the filtered oil to the pan. Given that most of us pamper our cars, the issues that resulted from ‘under maintained’ oil filters are not likely to reoccur, plus that issue was only for the hydraulic tappet engines. I also question the sensibility of directing some fraction of the oil pump capacity just to filter the oil . . . not that filtration isn’t important, but I would prefer to use the entire oil pump capacity to lubricate the engine. There will be a short piece of tubing connected to the upper tappet gallery fitting . . . that’s the one that’s removed when installing an oil filter (step 4 in the instructions). Think about the direction of the oil flow, which is from the lower port on the engine block to the upper port on the engine block. You connect the lower port on the engine block to the upper port on the oil filter (note step 2 is defining the side port on the filter as the ‘INLET’). You then connect the lower port on the oil filter (marked ‘OUTLET’) to the upper port on the engine. See attached photo . . . it’s a 22nd series 288. dp

Posted on: 2022/7/30 20:52

|

|||

|

||||

oil filter.jpg (225.88 KB)

oil filter.jpg (225.88 KB)