|

Re: weatherstriping

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Kanter's product is Steele Rubber product I believe. He's sometimes a bit cheaper than buying directly from Steele. If you want very good quality, exact or very nearly exact reproduction of the original stuff, Steele either directly or via Kanter is the way to go. If your budget won't allow, I guess there is lots of generic stuff out there that might suffice.

Posted on: 2008/10/30 12:34

|

|||

|

||||

|

Re: weatherstriping

|

||||

|---|---|---|---|---|

|

Home away from home

|

thanks for the info owen, and as always thanks for the quick reply!!

Posted on: 2008/10/30 12:36

|

|||

|

Daily Driver:

|

||||

|

||||

|

Re: weatherstriping

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Second owens recommendation for the weatherstrip but for some items you might also need, check Metro out. They have some things that steele doesn't as well as universal items such as grommets etc.

metrommp.com/

Posted on: 2008/10/30 12:42

|

|||

|

||||

|

Re: weatherstriping

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I am just now swearing at Steele rubber and have to call Kanters because of some problems with the vent window weatherstripping. I will cover it further when I detail the rebuilding of the vent windows.

Posted on: 2008/10/30 14:43

|

|||

|

||||

|

Re: weatherstriping

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

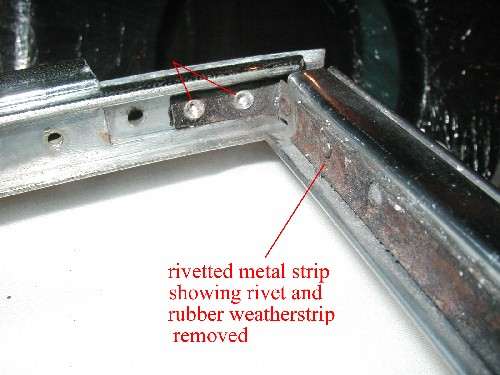

I called Kanters and talked to Stuart. Steele has metal imbedded in this strip of rubber - Packard part #474352 (GRP 30.4335). I don't know why unless they intended for you to drill out the rivets, discard the original strip of metal and then re-rivet their part to the divisor bar. I guess I'll just cover it with flat black paint.

Another compromise but not much I can do about it. The C-shaped piece that also goes in the vent casting, which DOES have imbedded metal, had one spot where it was not drilled and tapped for a 6-32 screw. Also the screws Steel provided were pan-heads, not flat screws that the casting was designed to accept. If you are doing this job, save all the original screws and put them in their proper holes in the old piece of rubber. That way you will know exactly which screws go where when you go to assemble the new rubber into the casting.

Posted on: 2008/10/30 15:46

|

|||

|

||||

|

Re: weatherstriping

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Wonder when they started putting the metal in. That was a complaint when doing the 54 Pacific. The strip had to be glued onto the existing metal and didn't stick for beans.. Just looked at their 54 piece and it appears to also have the metal now as there is no mention of cementing it in. What size are the rivets? Any chance of drilling old out and then tapping the casting for a small filister head screw or similar? I see that Micro Mark has several types, and you being a train guy probably have them all.

Posted on: 2008/10/30 16:39

|

|||

|

||||

|

Re: weatherstriping

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Howard, some good suggestions. There is no need to drill the rivets out. I made that mistake on one piece and had to rerivet the strip back to the stainless piece that is fastened to the divisor bar. Weatherstripping cement will hold that strip of rubber in just fine. I'm going to place a strip of wood on top of it and clamp it wth some C-clamps. The rivets don't go into the casting at all, but just into the stainless piece. I would think the 51-54 castings were handled in the same way. I am going to document the steps I went through to have the vent wings rebuilt. I still need to find someone with the clamping glass tool so I can remove the glass from the frame as I want to rechrome it also.

Posted on: 2008/10/30 17:25

|

|||

|

||||

|

Re: weatherstriping

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Randy, thanks for pict. I didn't remember the 54 having that wide of strip though.

Regarding the clamping tool--If you can't find someone with one, could you make your own by using a couple of toggle clamps mounted to a piece of plywood? Looking at the glass, would think 2 spaced 6 inches apart and corresponding pads mounted directly underneath to take the pressure and raise the window a bit would be fairly easy to make and not too expensive. A lever and hook on each end of the frame to grab it would complete the deal. www1.mscdirect.com/CGI/N2DRVSH?PMSECT=0000000485&KNC-T7L391316886

Posted on: 2008/10/30 20:18

|

|||

|

||||

(95.17 KB)

(95.17 KB)