|

Re: 1955 Torsion Level Problem

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Assuming corrosion or rust has not been a factor and the springs holding the brush housings to the commutator are free and brushes are both making good electrical contact with the commutator then as long as 12v is reaching one or the other of the terminals depending on direction the assumption is the motor is OK.

Look at the transverse bars between the compensator and short bars on either side, particularly the long one which is on the rear side of the compensator. If the bars are bent there is a good chance something failed at one time and there could be damage inside. If the bars look to be OK or just a tiny bend then on a 55 there is also another possibility, albeit slim after all these years, but still maybe worth checking Download tech bulletin 55T-12packardinfo.com/xoops/html/downloads/STB/55T-12.pdf and have a read thru. It mentions a problem that could be the issue but if not, it still gives the procedure for removing the motor. Once the motor is off you can use a screwdriver or rig up something to work with a drill or ratchet to manually try and move the compensator. The gearing is tremendous and in a manual move you can crank or turn for several minutes before the bars move enough to see. If it moves chances are it is OK internally and the motor is the issue but if it doesn't want to move or seems very rough then there is damage inside and the section on unloading the bars to remove the compensator becomes important.

Posted on: 2019/6/22 15:10

|

|||

|

Howard

|

||||

|

||||

|

Re: 1955 Torsion Level Problem

|

||||

|---|---|---|---|---|

|

Home away from home

|

Do you have the ability to see under the car when the TL system is trying to work?

You can hear the motor trying to level the car? On 2 different occasions I had leveling issues on my 55 Patrician. One was the ring gear spinning but no leveling. I took off the motor and gearbox and fixed that issue. But I saw it, so that is the reason I asked about being able to see under the car when the system is trying to work. The second time on my 55 Patrician I was working under the hood and noticed when the system tried to level, I had a broken bolt and the long bar raised up the front upper A arm. Look forward to hearing about your diagnosis of the issue.

Posted on: 2019/6/22 22:52

|

|||

|

||||

|

Re: 1955 Torsion Level Problem

|

||||

|---|---|---|---|---|

|

Home away from home

|

When I ground each limit switch terminal the motor armature moves slightly in each direction but doesn't spin at all, only taking up the slight play.

The compensator arms don't appear to be bent. It appears the compensator gearbox is jammed. Without an ability to move it, one can't relieve the torsion bars which I would expect makes the gearbox removal rather difficult and dangerous. It also looks like the motor may not be removable with the exhaust pipe in place. This looks like a job for the dealer.

Posted on: 2019/6/29 17:57

|

|||

|

1942 Clipper Club Sedan

1948 Custom Touring Sedan (22nd Series) 1955 Patrician Sedan 1955 Four Hundred Hardtop Coupe |

||||

|

||||

|

Re: 1955 Torsion Level Problem

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I wholeheartedly agree but in my part of the country Packard dealers are not easily found. I suspect the same might be where you live too.

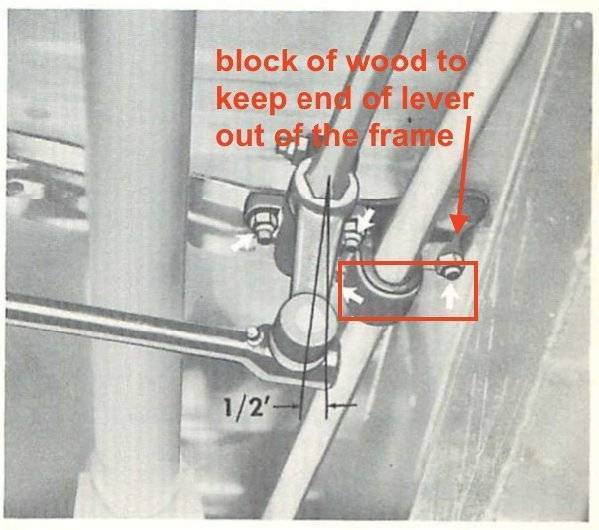

The motor slides off and should clear the factory exhaust. As I recall it only needs roughly 2 inches and a slight tilt. There is a sleeve connection between the armature and the worm gear it drives which will separate. The motor and armature can slide off the worm shaft and clear the mount on the compensator housing. It could be someone has done exhaust work and ran the pipe too close to the motor at which point I don't have a suggestion. As to unloading the bars, the bulletin I linked above has the procedure. Basically it involves loosening but not removing some bolts that clamp the two halves of the housing together. The ring gear surrounding the planetary is a friction fit between the two halves and loosening the bolts which surround the ring relieves the friction pressure. That allows the tension of the bars to rotate the entire ring which slips but stays in the compensator. Use care though and keep hands clear of any of the bars or mechanism that move at the bottom of the compensator. The ring is under a lot of tension and even though there is a bit of control by carefully loosening the last bolt and being able to tighten it again the ring could suddenly break free letting the bars around the compensator move quickly. I would also suggest placing some wooden blocks about 3-4 inches long so they will sit between the frame rail and the middle to end of the lever on the ends of the short bars where the transverse bars are attached. Tape or attach them to the frame in some way so they don't fall off or down far enough to obstruct the screw on the end of the transverse bars. Once the tension is released the levers on the short bars will move. Depending on the position of the car the lever on the end of the short bars may want to swing into the cavity of the frame rail. Very rarely will unloaded bars stick to the 1/2" toward the center dimension the manual says because that depends on the car, how it is optioned and how it was sitting when the tension is released. The blocks may not be needed and can then be removed but if they are needed and not present the job becomes a lot harder. If the end of the levers swing too close to the frame getting a drag link socket on the screw on the end of the bar to loosen it and remove the transverse bars so you can remove the compensator will be extremely difficult if not impossible. Sometimes the screw at the compensator end can be reached but not always. There is no way to bring the levers back out again without a lot of effort in repositioning the rear of the car and then holding it there.

Posted on: 2019/6/29 18:47

|

|||

|

Howard

|

||||

|

||||

|

Re: 1955 Torsion Level Problem

|

||||

|---|---|---|---|---|

|

Home away from home

|

Just so I'm clear, to remove the motor there's just the two wired connections and the two through-bolts, then the whole motor with armature can be pulled away?

BTW, there is a large hole in the rubber boot on the tailshaft of the transmission and due to a bit of leakage over time and evidence this car was driven extensively on dirt/gravel/rock/mud roads the gearbox, limit switches, bars and the surrounding area are heavily covered in hardened grime. The limit switches can't even be seen and along with the bolt heads will have to be extricated like a fossil. On the upside none of it is rusty but it's a big, hard grease ball. I've chipped and scraped the grime and rocks away from the bars so they should be free to move but they don't move in either direction in the slightest. I assume the car continued to be driven in these conditions after the leveler system failed. Part of my immediate difficulty (and resulting questions) is having so much of the system concealed from view. This job is going to make me really wish I had a lift. Also, do you think an auto-electric place that tests and rebuilds generators and starters will be able to test this motor if I brought it to them, or is this thing so unique they wouldn't have a clue?

Posted on: 2019/6/30 10:05

|

|||

|

1942 Clipper Club Sedan

1948 Custom Touring Sedan (22nd Series) 1955 Patrician Sedan 1955 Four Hundred Hardtop Coupe |

||||

|

||||

|

Re: 1955 Torsion Level Problem

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Yes, two thru bolts and the connections. The motor will need to slide straight back about 3/4 inch to clear the pins out of the slot in the sleeve and then you can either pull straight back another 1" to clear the housing or else start tilting the motor and work the shaft out to clear the compensator case. Try and keep the brush end of the motor down so the armature doesn't drop out of the motor.

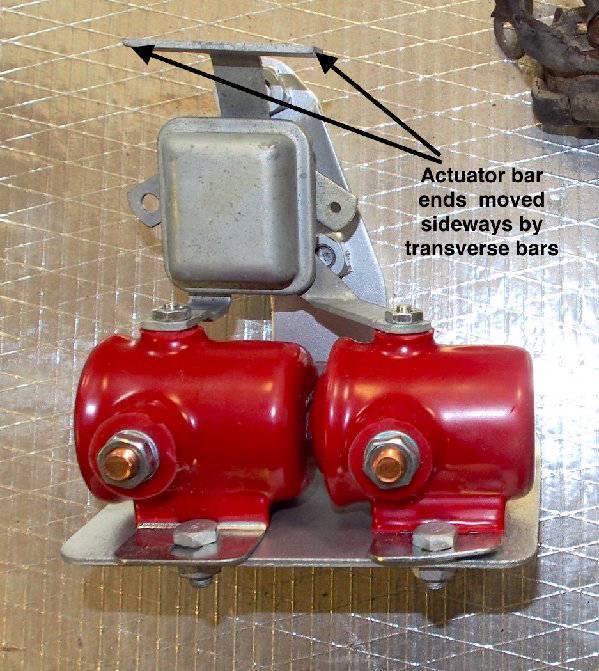

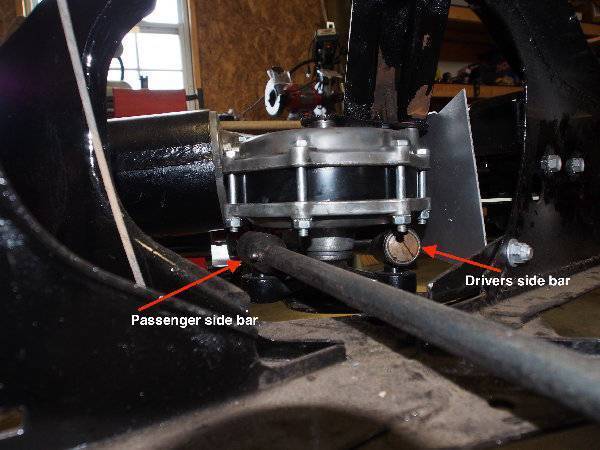

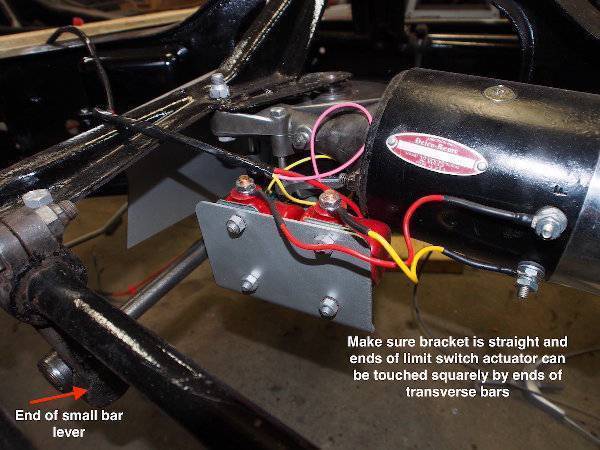

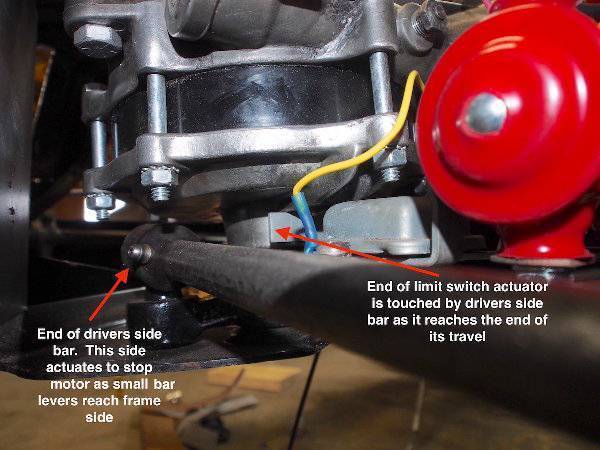

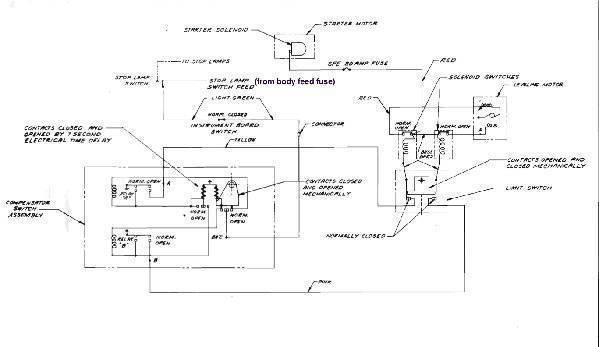

Once you get the motor off you can rig up something to fit the slots in the sleeve and see if you can turn the worm by hand. If you can and after MANY turns start seeing the bars move then the compensator may be OK. If you run into the same resistance the motor is apparently seeing then the compensator will need to come off. Before removing the compensator it would be a good idea to do the measurement in the bulletin to check if the slotted end of the sleeve is extended out about 3/8" away from the seal or back of the recess around the sleeve. If it is the motor I have no idea if a motor shop would be willing to work on it but they would need the entire compensator (or at least the upper case half) since the compensator housing provides the armature bearing on one end. There is nothing special electrically except for the fact Packard used two independent but reverse wound field coils to change motor direction. Only one field coil is active at a time. The armature is probably fairly standard. The thing most people today who are familiar with other reversible motors seem to find hard to grasp is the case is grounded and depending on direction, only one of the terminals gets power. Most see two terminals or wires sticking out and think of modern permanent magnet motors where both terminals get power and to reverse, just change the connections. NOT SO! Here are a few photos of the motor removed and the 55 solenoids and limit switch bracket. The bracket photos are courtesy of Stewart and was taken when he did his 55. The solenoids are modern replacements. If you don't already have one here is a schematic of the 55 system showing all the internal relay and switch contacts and the motor. Attach file:  (179.67 KB) (179.67 KB)  (133.42 KB) (133.42 KB)  (95.38 KB) (95.38 KB)  (148.72 KB) (148.72 KB)  (204.74 KB) (204.74 KB)  (130.37 KB) (130.37 KB)  (118.59 KB) (118.59 KB)  (65.56 KB) (65.56 KB)

Posted on: 2019/6/30 11:16

|

|||

|

Howard

|

||||

|

||||

|

Re: 1955 Torsion Level Problem

|

||||

|---|---|---|---|---|

|

Home away from home

|

Just to follow up, I pulled the motor. That took a little longer than it should have as I discovered the through bolts were not threaded into the casting but had nuts that couldn't be seen. That wasn't a big problem but I assumed the nuts were the same size as the bolt heads and just couldn't get the wrench to do any good on the grease covered nuts until stepping up a size.

The motor windings looked fine. I grabbed the armature and tried turning it by hand. It was locked solid in both directions, as I expected. The mandrel it meshes with looked like it should -- no snap ring problem. Next, I figured if the gearbox was damaged I couldn't really do much more damage by trying to break it free first -- perhaps I could get a feel for the nature of the damage. I put a strap wrench around the armature and turned with considerably more force. It broke free and I was able to keep turning with the wrench in that direction. I then reversed the wrench and went back the other direction, expecting to hit a bad spot. Instead, it kept moving smoothly the other direction, past the starting point. Hmmm, things are looking up. I reassembled the motor and discovered it now runs in both directions, though acts as if it's straining some, running kind of slow, but that could be electrical as my ground connection is iffy jumpering those contacts. Anyway, I'm quite pleased the gearbox doesn't seem to be damaged. I was not looking forward to replacing that. Thanks for all your help!

Posted on: 2019/7/6 10:20

|

|||

|

1942 Clipper Club Sedan

1948 Custom Touring Sedan (22nd Series) 1955 Patrician Sedan 1955 Four Hundred Hardtop Coupe |

||||

|

||||

|

Re: 1955 Torsion Level Problem

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Glad it came free but definitely keep your eye out for more problems. The compensators are very nicely constructed and do not lock up for no reason. Conceivably something could have gotten inside the case and wedged between gears or a tooth or part of the casting was broken and wedged. You managed to get it free with your actions but if something is floating around it could come back around and jam again. You said you didn't see evidence of bent transverse bars so at least that is a good sign but just stay aware and we will hope the problem does not recur and cause some extensive damage.

Posted on: 2019/7/6 10:57

|

|||

|

Howard

|

||||

|

||||

|

Re: 1955 Torsion Level Problem

|

||||

|---|---|---|---|---|

|

Home away from home

|

The first reduction in the compensator is a worm drive and the worm is supported by a ball bearing that is lurking behind a freeze plug that points straight forward at the top of the unit. The "mandrel" you mentioned is actually the worm. In damp climates condensation will collect in the top of the housing and that bearing will be the first to seize. If you wish to thoroughgoing, you'll want to replace that $7 bearing. Levelers that are noisy or howl invariably have damage to that bearing and often a rusty flaky worm.

I have drilled a hole into the freeze plug and squirted oil in. Even if you grease the unit as specified, there is a good chance the grease simply won't get there.

Posted on: 2019/7/6 19:39

|

|||

|

||||