|

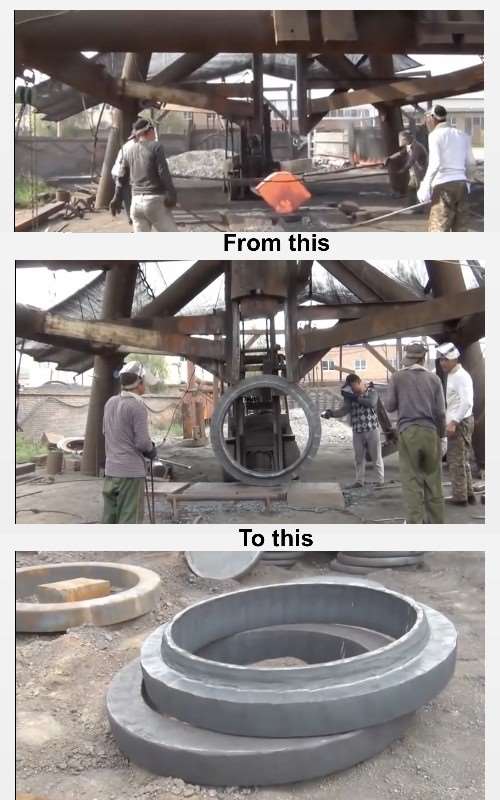

Old style ingenuity.

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I wonder if there are any US craftsmen that could still do this large forging with nothing but a pair of forklifts, drop hammer, steel blocks and grunt labor. The video looks to be real time so aside from the reheat time it appears to have taken less than 20 minutes.

Posted on: 2016/12/16 14:59

|

|||

|

Howard

|

||||

|

||||

|

Re: Old style ingenuity.

|

||||

|---|---|---|---|---|

|

Home away from home

|

And not an earplug in sight. Those guys will be completely deaf after a few years. Excellent video and shows what craftsmen the early blacksmiths were. PT

Posted on: 2016/12/16 17:46

|

|||

|

I like people, Packards and old motorbikes

|

||||

|

||||

|

Re: Old style ingenuity.

|

||||

|---|---|---|---|---|

|

Home away from home

|

train wheels?

(o[]o)

Posted on: 2016/12/16 22:41

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: Old style ingenuity.

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I think is is a flange for joining large pipes. Just needs to be machined to finish it off.

The TV show "How its Made" showed a video on making train wheels here in the US. Same type solid billet to start but after a hole was punched in it some kind of machine spun the billet at high speed so centrifugal force enlarged and thinned the hot steel. After that operation they moved it to a press where a huge hydraulic ram came down and stamped the metal to rough finish shape. It took two or three molds with a a single press in each mold. Then on to finish machining for the bearing and rail surfaces. They probably make flanges the same way over here..

Posted on: 2016/12/16 23:20

|

|||

|

Howard

|

||||

|

||||

(134.46 KB)

(134.46 KB)