|

Re: 55/56 QUESTION

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

If you mean the stock trans oil cooler, it mounts to the engine and not the cross member. It can be installed with the engine in place.

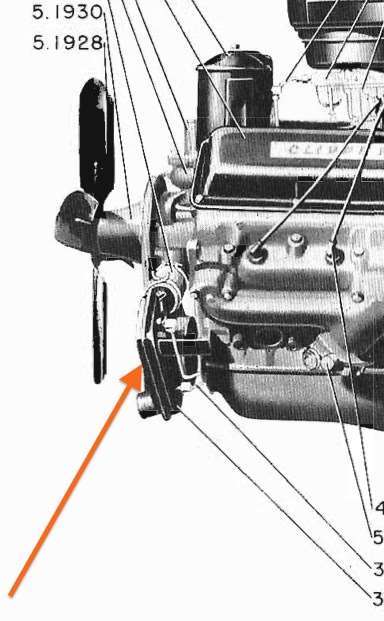

The lines also mount to the side of engine but run in the space under the motor mount and exhaust manifold on the passenger side and then under the damper. With the engine and radiator in place, you can do them from under the car but may be a bit of work getting them bent around to the cooler while clearing the cross member and damper. Attach file:  (37.62 KB) (37.62 KB)

Posted on: 2014/4/25 8:38

|

|||

|

Howard

|

||||

|

||||

|

Re: 55/56 QUESTION

|

||||

|---|---|---|---|---|

|

Home away from home

|

Then this leads to another question. Is it easier to install these lines from the top of the engine, or get the car up on a lift and install them from underneath.

Posted on: 2014/4/27 8:09

|

|||

|

Al

1955 Patrician |

||||

|

||||

|

Re: 55/56 QUESTION

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

With the engine in the car, I don't think it will be particularly easy from either direction. It all depends on what is already mounted. If at all possible, I would suggest you install those lines before the engine is mounted.

From the top you have a very limited area in which to feed the lines. You will also be working with the long length of lines so the car will have to be high enough that there is room to twist and aim. If the radiator and splasher is out then possibly you can get a low enough angle to feed the lines in above the crossmember and into general position but I think it would still be difficult. IMO, while still a project, coming from the bottom would be easier. You will still have some difficulty threading around some items but since the lines go between the engine and other components sticking down or bolted to the frame, I think you would have better luck working from the center of engine and then twist lines up and out into position -- as long as it is not a center post lift. You would be working with the short bend end of the lines so as long as those were started at an angle and get up past the cross member you should be able to walk the long part into position and get the short ends under the damper at the same time. I do believe you will have to remove a couple of things. The engine oil dipstick and possibly the trans fill tube as starters. Maybe the idler end of steering will need to drop. I think the rest could be threaded around with minimal bending and/or rebending of the lines. Here's a photo of my car from the top and then few photos of the route taken courtesy of an old engine (wasp nest optional). Note how lines bend up and then down to go behind the exhaust and motor mount and behind the dipstick. Others probably have more recent experience so take their advice if it comes.

Posted on: 2014/4/27 10:16

|

|||

|

Howard

|

||||

|

||||

|

Re: 55/56 QUESTION

|

||||

|---|---|---|---|---|

|

Home away from home

|

Well fortunately or unfortunately depending on viewpoint, the engine is in the car, the radiator is out. I have no lift so I will have to find a mechanic with a lift. The best I can do would be to raise the front end and set the front end on blocks. I just do not know if that will get it high enough.

Attach file:  (89.87 KB) (89.87 KB)

Posted on: 2014/4/27 10:43

|

|||

|

Al

1955 Patrician |

||||

|

||||

|

Re: 55/56 QUESTION

|

||||

|---|---|---|---|---|

|

Home away from home

|

Just my two cents.

I am planning to eliminate that transmission cooler altogether as I rebuild the engine. Will install new lines, running them under the radiator and mounting a modern cooler to the base plate between the radiator and the bumper. I don't have it all the details worked out yet as I am not at that point yet but I have seen it done.

Posted on: 2014/4/27 13:33

|

|||

|

Stewart Ballard

|

||||

|

||||

|

Re: 55/56 QUESTION

|

||||

|---|---|---|---|---|

|

Home away from home

|

Well I had thought of the same thing. I was thinking of just replacing the metal tubing with rubber. That way I can route them where ever I want.

Posted on: 2014/4/27 21:23

|

|||

|

Al

1955 Patrician |

||||

|

||||

|

Re: 55/56 QUESTION

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Stewart- I don't think it's a good idea to think that Packard engineers selected a liquid/liquid heat exchanger (it's both a heater and cooler) for the transmission oil rather than a simple air/liquid cooler without forethought of the conditions that would be encountered. You might think about the following two possibilities:

1. Assume you are stuck on an extremely hot day in traffic that just crawls at 5 mph or less for an hour or more. You're in torque converter so you'll be generating huge amounts of heat but you'll have no airflow over your cooler other than what the fan might draw at an idle speed or close to it and thus little or no cooling of the fluid. With the factory unit you'd still be cooling to whatever the coolant temperature happened to be. If the situation lasts long enough (and it did to me), bye-bye transmission friction surfaces. 2. Let's say with your air-only cooler you'll be driving at reasonable road speeds on a cold day. The temperature with the wind chill factor at the cooler could easily get to below 0 F.; on a very cold day even 20 or 30 degrees below 0, and the fluid will never warm to operating temperatures, pressures will be very high, liquid flow will be reduced and lubrication will be sacrificed. The factory cooler is very efficient and also due to internal construction of the core in stainless steel, failures are almost unheard of. If you must install an air cooler forward of the radiator, put in in series with (and before) the factory unit. In that manner in extremely hot conditions it will remove some heat and decrease the amount of work the factory cooler will have to do. And in very cold weather it may take the fluid to extremely low temperatures but the factory unit may still be able to warm the fluid sufficiently to avoid problems.

Posted on: 2014/4/27 22:11

|

|||

|

||||

|

Re: 55/56 QUESTION

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I did add an air cooled heat exchanger and ran it in series with the original exchanger for the very reason stated. I have driven over 30,000 miles with that setup and it still functions well. I have never doubted that Packard engineers were the best in the business.

Posted on: 2014/4/27 23:23

|

|||

|

||||

|

Re: 55/56 QUESTION

|

||||

|---|---|---|---|---|

|

Home away from home

|

I, KevinAZ and Paul in Las Vegas have all eliminated the stock Packard transmission cooler (really a heater) and replaced it will an air cooled one with rubber lines in front of the radiator. It's been working for me for 14 years without a glitch from the T-U or anything else. As I understand it, same with KevinAZ and Paul.

The conversion is really easy and the lower rad hose to replace the cooler is a standard Mustang one (see the Xref). I think the Packard engineers screwed up on that one. Craig

Posted on: 2014/4/27 23:31

|

|||

|

Nuke them from orbit, it's the only way to be sure! Ellen Ripley "Aliens"

Time flies like an arrow. Frui |

||||

|

||||