|

Re: ''55 400 torsion level compensator gearbox

|

||||

|---|---|---|---|---|

|

Home away from home

|

Have you read the service manual?

Start on page 8 of the suspension section XVI, packardinfo.com/xoops/html/downloads/ser ... 5556/Sect16_Suspension_Steering.pdf The bottom of page 10 figure 22, may answer your question. Or Figure 44 on page 15 addresses your question better.

Posted on: 2017/7/22 13:15

|

|||

|

||||

|

Re: ''55 400 torsion level compensator gearbox

|

||||

|---|---|---|---|---|

|

Home away from home

|

You do not need any special tools to remove the compensator, but you will find that without it the back of the car will sit very high. Under most moderate loading conditions the compensator pulls the back down rather than pushing it up.

Avoid the temptation to put the car in use without automatic leveling, and in particular without an operating limit switch. That is how yours got broken along with MANY others I have seen over the years. It is very easy under manual operation to get confused and run the device over center and end up bending the connecting bars around the gear box. Too clever by half is a very apt expression.

Posted on: 2017/7/22 14:02

|

|||

|

||||

|

Re: ''55 400 torsion level compensator gearbox

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

By all means read thru the suspension section to get an idea of how things are connected together.

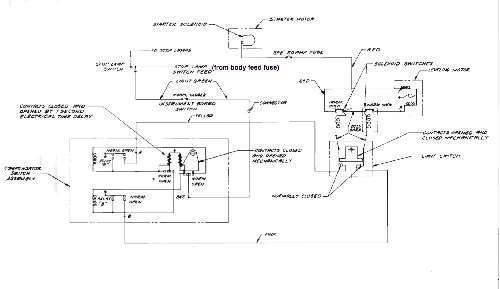

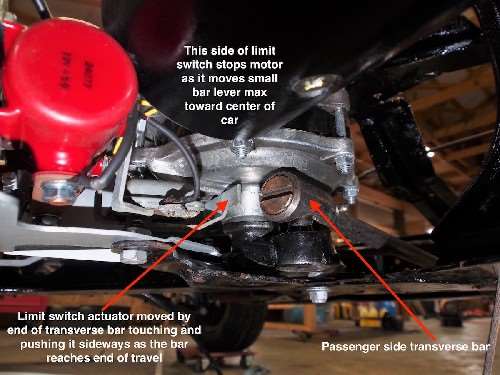

To answer the first question, yes you can drive the car without the compensator working. What you may find however is since the car is basically balanced like it was on the center of a teeter totter, road conditions -- bumps, acceleration, braking etc -- can unbalance the car and one end may raise or lower on its own. The compensator would take care of that but without it you may periodically have to adjust manually by pushing one end or the other down by hand to get it level again. How frequently that would be needed is unknown. The holding tool will be of no use when working on the compensator because it only holds one end of the long bars so the A arms and other front suspension pieces can be worked on. It is the load on the transverse and short bars that needs to be relieved before the compensator can be removed and those are not affected by the tool.. The dimension in figure 22 mentioned above may or may not be correct for your car. Typically the 400 has a lot of options so one end may be heavier or balanced differently than the bare bones car. Different weight distribution or different links in front than the factory used on the car the photo was taken from and the lever can be off as much as an inch in either direction from the amount shown in the illustration when the car is level. If the motor and compensator is working, with the motor disconnected you can electrically move it. Bring a large jumper wire down from the hot side of battery and while you are watching, barely touch it to one or the other of the motor terminals to move the compensator one direction or the other. One direction will seem to strain and the other in the direction needed to release tension will tend to move farther and faster. When you can grab hold of a transverse bar and twist to rotate it by hand the load is off. If the compensator cannot be electrically operated, there are two ways the load can be relaxed. The first and probably safest is by carefully removing the motor and sliding the armature out of the worm connector. Then using a large screwdriver in the worm gear, manually turn the worm in the direction needed to release the tension. One direction will be fairly hard to turn and the other relatively easy so figuring out the direction needed should not be too hard. The gear ratio in the compensator is considerable so that rotating the worm can take some time to do if it needs to move far. Some have used a ratchet and others have worked up something to attach the screwdriver to an electric drill to do the turning. If the compensator is damaged and won't move, the other method is to loosen but DO NOT REMOVE the 6 or 7 bolts holding the top and bottom half of the compensator together. The load will cause the transverse bars to want to rotate the planetary gears and with the bolts loosened the center ring will want to turn along with the gears until there is no more load. The downside to that method is there is no control and once the ring is loose things will happen in a hurry. No matter which method you use keep your hands clear of the transverse bars and link at the bottom of the compensator. If it were mine and the electric method was impossible I would remove the motor. Since you will also have to use a ratchet and drag link socket to remove the plugs at the end of the transverse bars in order to remove the bars and compensator, I would also have two wooden blocks maybe around 7-10cm prepared to slip between the lever and the inside of the frame rail. They may not be needed but if it should happen the no load point is going to place the end of the transverse bars too far toward the inside of the frame rails the wood blocks can be inserted to prevent the levers going into the frame rails far enough the space needed for the socket is too tight. Once the levers are blocked then turn the compensator until there is no load and you can rotate the transverse bars. Ross brings up a very valid point about the limit switches. Since the 55 has the switch on a bracket under the car and operated by the transverse bars moving the switch actuator to one side or the other, be sure the bracket is not bent and the end of the actuator meet the transverse bar squarely and securely. The switch actuator should be moved slightly to cut power when the transverse bar approaches limit and not be able to allow the transverse bar to slide over or under the switch actuator. In case you don't have one, here is a complete electrical schematic of the 55 assy showing all the contacts.

Posted on: 2017/7/22 14:14

|

|||

|

Howard

|

||||

|

||||

|

Re: ''55 400 torsion level compensator gearbox

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

Many thanks guys for all the information.

Posted on: 2017/7/23 3:08

|

|||

|

||||

|

Re: ''55 400 torsion level compensator gearbox

|

||||

|---|---|---|---|---|

|

Home away from home

|

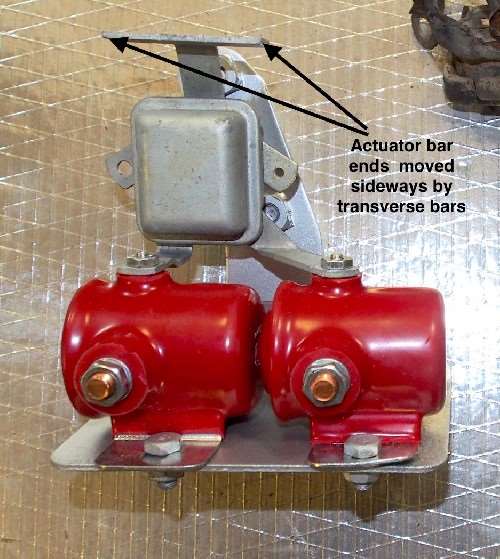

What is that big red round thing in the upper left quadrant of the picture???

Posted on: 2017/7/23 7:01

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: ''55 400 torsion level compensator gearbox

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

What is that big red round thing in the upper left quadrant of the picture??? One of the solenoids. These are Stewart's photos of his 55. He bought new PVC coated Cole-Hersee solenoids when rebuilding his unit.

Posted on: 2017/7/23 8:51

|

|||

|

Howard

|

||||

|

||||

|

Re: ''55 400 torsion level compensator gearbox

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

Having read and re-read the manual describing the torsion level system. My understanding is that normal suspension movements of the rear load arms will induce some rotary motion to the compensator bars and thus the compensator links, which will all be reacted at the compensator itself. So despite this being none operational in my car, it will still be subject to loading so it's secure attachment to the car essential. I would appreciate any sanity check of my analysis, thanks.

Posted on: 2017/7/24 14:13

|

|||

|

||||

|

Re: ''55 400 torsion level compensator gearbox

|

||||

|---|---|---|---|---|

|

Home away from home

|

Hammy,

Do you have any pictures of the broken parts? That might help seeing what you are describing. Do you have a car lift to look under all of the car? Where is it broken? packardinfo.com/xoops/html/uploads/newbb/5209_56a559dbda0d3.jpg packardinfo.com/xoops/html/uploads/newbb/5209_56a5576b391d3.jpg packardinfo.com/xoops/html/uploads/newbb/491_48a49aed37ac0.jpg FYI, Some period films about Packard torsion level on YouTube. m.youtube.com/watch?v=8Sz0RZUySk0 m.youtube.com/watch?v=pQcPALPnTKU

Posted on: 2017/7/24 15:41

|

|||

|

||||

|

Re: ''55 400 torsion level compensator gearbox

|

||||

|---|---|---|---|---|

|

Home away from home

|

You are correct. In any event it must be securely attached to the car.

Posted on: 2017/7/24 16:30

|

|||

|

||||

(62.35 KB)

(62.35 KB)