|

Re: 1940 Super 8 160 Model 1803 Project

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Began cleaning the exhaust manifold and found a crack in the neck facing the intake. Rats! Talked with Flackmaster a bit and thought about options. Decided to stay with this manifold since it is not in bad shape and is only cracked where many of these usually are.

I drilled each end of the crack to stop further spread and relieve the stress. I than veed the crack out and dressed the surface to allow maximum penetration and the best possible repair. I have not yet decided what material I will use, brass or ni-rod. Will think on it this week. I welcome anyone's advice that has successfully made a repair where this manifold is cracked. I continued working on some unsightly pits on the far ends with flapper wheels, and small stones in the Fordum tool. All was looking very well They turned out very nice! In all a very enjoyable day of work. While I'm not thrilled about the crack, I am not terribly bothered by repairing it.

Posted on: 2011/5/22 23:09

|

|||

|

||||

|

Re: 1940 Super 8 160 Model 1803 Project

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

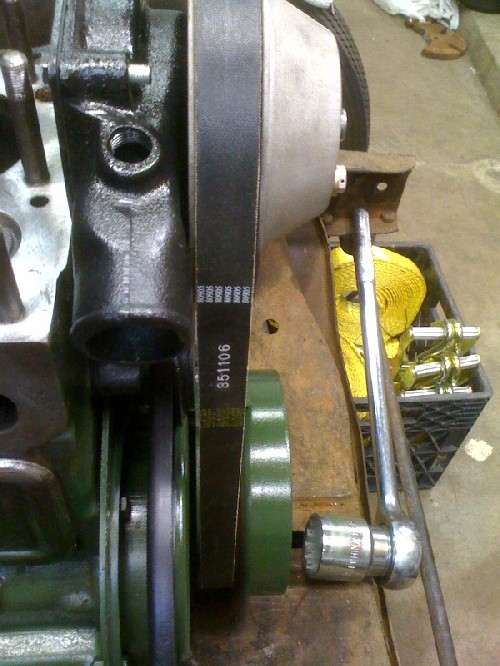

Tonight consisted of figuring out what the difference between a '40 and '41 - latter pump is. Answer: about .400". The hub on a '40 is pushed back farther because '40 runs a very thick cast pulley v. the '41 and latter that is fabricated from a sheet metal stamping.

The castings are no different, according to the parts books and the pumps at my disposal. I mention about .400" because I am suspicious the hub on the pump in my car was actually pushed a little to far back during rebuild at some point. So, having a '40 356 and a pump with the hub backspaced for '41 application what to do? I opted to make a pushing collar that would allow the hub to be pushed to the depth calculated for proper pulley and belt alignment. After a few hours, the tool was finished, and hub pressed into proper alignment. With a quick mockup, proper alignment was achieved. While I am sure this is not terribly interesting, I hope it may explain the pump differences for those who were not aware. Attach file:  (41.86 KB) (41.86 KB)  (33.42 KB) (33.42 KB)  (42.72 KB) (42.72 KB)  (44.69 KB) (44.69 KB)  (45.58 KB) (45.58 KB)  (34.30 KB) (34.30 KB)  (40.09 KB) (40.09 KB)  (43.62 KB) (43.62 KB)  (38.40 KB) (38.40 KB)  (53.15 KB) (53.15 KB)

Posted on: 2011/5/24 0:48

|

|||

|

||||

|

Re: 1940 Super 8 160 Model 1803 Project

|

||||

|---|---|---|---|---|

|

Home away from home

|

Interesting that the 1940 fan pulley is different from the later ones, however only the junior cars used a stamped sheet metal pulley. The 1941 to 1950 fan pulleys for the 356 engine were still a fairly heavy casting.

It looks like the later ones had a longer tapered section in front of the belt groove. Dimension on the one illustrated is 3-3/16' from the back of the pulley to the front of the raised ring at the front.

Posted on: 2011/5/24 1:37

|

|||

|

||||

|

Re: 1940 Super 8 160 Model 1803 Project

|

||||

|---|---|---|---|---|

|

Home away from home

|

Well, Jim, it was fairly obvious. I would have done exactly what you did with that water pump, if I knew what I was doing. I missed why you wanted to put a more modern pump on your car than the one it had. But that's ok. Looks great.

Posted on: 2011/5/24 2:00

|

|||

|

||||

|

Re: 1940 Super 8 160 Model 1803 Project

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Brian, that is fantastic information! It is very interesting to learn the '41 and latter pulley was still cast, and even more so to learn they had a deeper dish. Upon reading this, I measured the '40 pulley and found it to measure 2 3/4" from back of pulley to raised flange in middle. Your finding of 3 3/16" on '41 and latter and my measurement of 2 3/4" on '40 yields a hub position difference of .438" deeper for '40. My guess that the one on the car was about .035" to deep, so it looks like I was within a few thousands of being dead on! Great news...

So... why .438" closer to the radiator? I wonder if perhaps the '41 radiator was that much farther form the front of the engine? Or, was it determined that bringing the fan that much closer to the radiator core offered a little more cooling efficiency? Thanks for helping solve the search for differences in the 356 water pump, and pulley mystery.

Posted on: 2011/5/24 2:10

|

|||

|

||||

|

Re: 1940 Super 8 160 Model 1803 Project

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

Joe, it really is not a latter pump, only a different hub position. Two reasons; one reason is some fellows were very curious what the functional differences were given the same casting was used yet the assemblies had different part numbers. The second reason was this rebuilt specimen arrived from Dallas, ready for research, comparison and installation in the Phoenix Packard research and repair division. An interesting conclusion to an otherwise mundane evening.

Posted on: 2011/5/24 2:15

|

|||

|

||||

|

Re: 1940 Super 8 160 Model 1803 Project

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

How much did AC pulleys have to do with the different hub locations.

Posted on: 2011/5/24 8:55

|

|||

|

Howard

|

||||

|

||||

|

Re: 1940 Super 8 160 Model 1803 Project

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Kinda hard to tell Jim - the casting numbers are(?) the same, and it appears your pump has a slightly different appearance to the casting/support "fins" towards the nose, and not on the new pump? have they been ground off for pulley clearance?

And the picture of the double pulley for AC - is this an exact reproduction of the original part, my curiosity is whether this width belt is available for Sanyo pulleys or ...? Very interesting information, especially for those who wish to have a spare waterpump on the shelf for their 40 or 41-50 356....and now, with or without A/C?

Posted on: 2011/5/24 9:17

|

|||

|

||||

|

Re: 1940 Super 8 160 Model 1803 Project

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

And the picture of the double pulley for AC - is this an exact reproduction of the original part, my curiosity is whether this width belt is available for Sanyo pulleys or ...?

Good questions, both. I bought the repro pulley and a casting of the compressor mount some 25 or so years ago. As far as I know, they are both exact. There was (is) a Sanden compressor with a 5/8 belt groove which would be very close. I do not remember for sure who made the parts although Jim Hollingsworth comes to mind as either directing me to the person or possibly doing them. I remember he sent a copy of a club chapter newsletter with an article on the prewar AC which is what got the purchase started.

Posted on: 2011/5/24 9:37

|

|||

|

Howard

|

||||

|

||||