|

Re: How much demand is there for PV8C oil pump adapter kits?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Jack -

I never noticed that much lugging in those GM cars in ordinary daily driving. A Monte with a THM 350C exhibited some bucking that was due to a failing TCC solenoid, but the engine continued to give many miles of trouble-free service after replacing that. I have to wonder if the situation with SBC bearings was more of a coincidence with the presence of a lock-up converter, yet rooted in some change in bearing material or supplier. Of course, I'm no master motor builder, either, but seem to have noticed a progression toward marginal materials and engineering with GM product over the last 30 years. When it comes to Packard, the very first Ultramatic that was introduced in 1949 had a Direct Drive (lock-up) clutch in the converter. Yet, we don't seem to have a problem of premature bearing failure in those cars.

Posted on: 2008/11/8 16:52

|

|||

|

||||

|

Re: How much demand is there for PV8C oil pump adapter kits?

|

||||

|---|---|---|---|---|

|

Home away from home

|

In regards to the lockup causing bearing problems Studebaker auto transmissions until 56 had a lock up clutch never heard of added bearing failures on there auto equipped cars. Also ford AOD has a l0ock up I have had 4 of these cars with lockups and no bearing or trans troubles with around 100000 miles per car. I had good luck with the the ford AOD. Never heard of other GM cars having extra bearing problems due to lock up 4 speed overdrives. Also how about all the cars with standard transmissions sure there have been a lot of drivers who liked to lug there engines down and use the torque a low RPM to pick up speed without down shifting.

Had a thought why not make the Packard gear root circle deeper below the gear toward the center of the gear would allow more oil in the cavity thus increase the amount of oil in each tooth void as it goes around and not effect the gear contact area.[img align=right width=300]<a href="http://s29.photobucket.com/albums/c281/sues98/?action=view?t=gear_terms.gif" target="_blank"><img src="http://i29.photobucket.com/albums/c281/sues98/gear_terms.gif" border="0" alt="Photobucket"></a>[/img] Attach file:  (3.41 KB) (3.41 KB)

Posted on: 2008/11/8 18:45

|

|||

|

||||

|

Re: How much demand is there for PV8C oil pump adapter kits?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Had a thought why not make the Packard gear root circle deeper below the gear toward the center of the gear would allow more oil in the cavity thus increase the amount of oil in each tooth void as it goes around and not effect the gear contact area Yes you could do what you describe, essentially emulating the GM high volume tooth root design on the Packard oil pump gears. There are three problems with this that I see: 1) You would have to have a gear-cutting machine or a very sophisticated machine shop make this mod. This would probably be more $$$ than the adapter and a new Olds pump, IMO. 2) This does nothing about the wear between the tip of the teeth and the oil pump housing, which occurs over time. As that wears, oil leaks from there too. Sometimes one cannot fix a worn out part without major ($$$) surgery. 3) The Packard oil pump is about 3 inches above the bottom of the pump to allow for the vacuum pump and it uses a "dropped" pickup. This increases the hydraulic "draw head" and is less efficient than the Olds pump which is at the bottom of the sump with the adaption. Thank you for thinking about this problem and taking the time to produce the GIFs. Craig

Posted on: 2008/11/8 23:59

|

|||

|

Nuke them from orbit, it's the only way to be sure! Ellen Ripley "Aliens"

Time flies like an arrow. Frui |

||||

|

||||

|

Re: How much demand is there for PV8C oil pump adapter kits?

|

||||

|---|---|---|---|---|

|

Home away from home

|

With a background in machining of more years than I care to remember and being a believer in KISS. The gear having ten teeth set up on teeth clamp to stops after set up one with indicator use cutoff wheel in a easy made home fixture cut to depth desired checking with depth mic to keep uniform depth no problem as I see it. Just a thought as I have spent little time thinking of this mod.

Posted on: 2008/11/9 0:25

|

|||

|

||||

|

Re: How much demand is there for PV8C oil pump adapter kits?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

With a background in machining of more years than I care to remember and being a believer in KISS. The gear having ten teeth set up on teeth clamp to stops after set up one with indicator use cutoff wheel in a easy made home fixture cut to depth desired checking with depth mic to keep uniform depth no problem as I see it. Just a thought as I have spent little time thinking of this mod. OK, fine, let's assume a simple fixture works. How do you deal with 10-teeth vs 7-teeth? 7-teeth take up less volume that 10-teeth, which leaves more room for oil.

Posted on: 2008/11/9 0:58

|

|||

|

Nuke them from orbit, it's the only way to be sure! Ellen Ripley "Aliens"

Time flies like an arrow. Frui |

||||

|

||||

|

Re: How much demand is there for PV8C oil pump adapter kits?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Look at the pics of the END of hte Packard gears that Craig posted on p3 of this thread.

Certainly a small amout of the gear root could be deepened. THere is not alot of room there tho. If the root gets too deep it will weaken the gear teeth. There is also a problem on the input gear with the key slot causing an even thinner area of support for the gear teeth if the root deepened. Maybe just not deepen those two particular roots. I doubt that any balance problems would occur by leaving 2wo of the roots stock but i wouldn't try to argue against it either. Owen: i'll look for an EARLY cam retainer plate when i get back. Will post pic when i find it. The ring for the LATE retainer has a flat cut on it that the early ring does not have. --=*=-- the flat is ez enuf to do by hand if u don't have a late ring.. --=*=-- EDIT 11/09/08 JV indicates below that the late ring is a different diameter than the early ring so early ring is not modifiable for use with the late plate.

Posted on: 2008/11/9 10:49

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: How much demand is there for PV8C oil pump adapter kits?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

i'll look for an EARLY cam retainer plate when i get back. Will post pic when i find it. The ring for the LATE retainer has a flat cut on it that the early ring does not have. the flat is ez enuf to do by hand if u don't have a late ring..

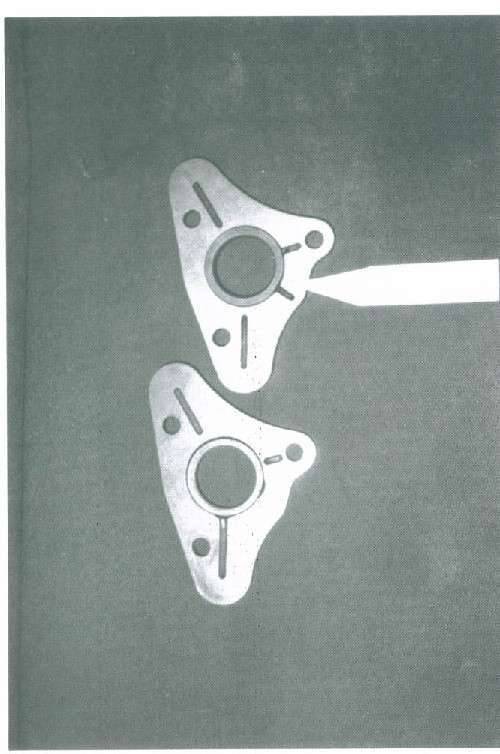

I look forward to your picture, as I'm still a bit confused on the matter. Here's a picture from Dick Benjamin's article on V8 oiling issues as published in The Packard Cormorant issue #69 (Winter 1992). He indicates the upper retainer is the "old style" with the arrow pointing to the changes; seems to me the arrow would point to the "later" spacer to show the changes? Looking forward to getting this clarified.

Posted on: 2008/11/9 12:29

|

|||

|

||||

|

Re: How much demand is there for PV8C oil pump adapter kits?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

ACOlds -

You're thinking along the same lines as I was. However, I was thinking of shopping for some new, off-the-shelf gears - with fewer teeth, greater root volume, but same OD - that could then be adapted for use in the Packard pump. I just haven't had time to get my ducks in a row and do the legwork. There are a lot of things to consider, and the devil is always in the details.

Posted on: 2008/11/9 12:56

|

|||

|

||||

|

Re: How much demand is there for PV8C oil pump adapter kits?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Owen -

I believe there is some editorial error in that piece, but it was never corrected by the publisher. Here is a pic of the late design plate and spacer, with a paper clip inserted (thanks to a tip from Keith) to indicate and additional passage that can't be seen otherwise. Attach file:  (16.33 KB) (16.33 KB)

Posted on: 2008/11/9 13:01

|

|||

|

||||