|

Re: Torsion Level again....

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The breaker could be weak and not holding but there could be a mechanical issue causing it to blow.

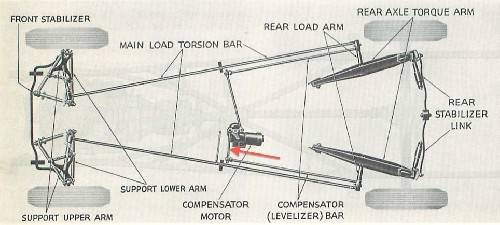

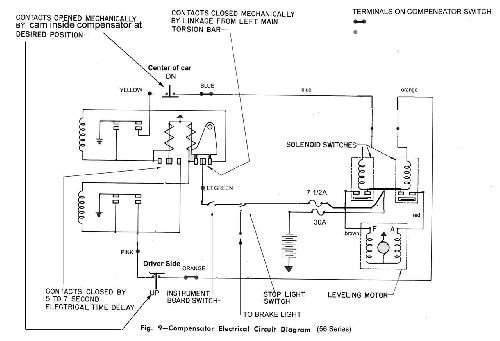

When it's on the lift, in addition to verifying all the wiring is intact note the condition and position of the transverse bars. Make sure the short bar on the drivers side pointed to by the red arrow in the photo is toward the front of the car. If there has been a prior electrical problem and motor kept running past the limit switches, the bars could have switched sides. Once that happens the system is confused & will keep trying to drive the bars in the direction called for to raise or lower. With the bars having switched sides that will be the opposite of what is needed. Trying to drive the proper direction results in the system driving the bars into the mechanism and blowing the fuse or causing more damage such as bent bars or sheared splines on the output yoke. If they have switched sides then they will have to be corrected. If the motor runs it can be done by disconnecting the motor from the control system and connecting voltage to one or the other terminal to run the motor in the direction needed to drive them back. If the motor won't run, it will have to be removed and the bars brought around manually by turning the worm drive by hand. If all is well in that respect then it's electrical troubleshooting and following the paths. Here is a 56 schematic showing the switches and contacts of a basic factory system without the optional manual override switch. One thing to note -- the solenoids are not the typical parts store starter type so if new are needed make sure to check the forum or xref for the proper replacement number.

Posted on: 2013/6/23 9:50

|

|||

|

Howard

|

||||

|

||||

|

Re: Torsion Level again....

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Thanks. But should it not be any movements when the motor is running? I was looking under the car during the few seconds it was running but there's no movement at all...

I'll take pictures on Wednesday how it looks under there.. /Jan

Posted on: 2013/6/23 10:24

|

|||

|

||||

|

Re: Torsion Level again....

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

At the moment I can only think of two things where the motor would run and the bars wouldn't move. Don't think you will be able to see either with just a visual inspection from the outside.

The first is where the worm screw end bearing has come out of it's position and allowed the worm drive to move away from the keyed pin to motor armature. If that is the case worm screw wouldn't be driven. Bearing is held by a snap ring but is behind a cover plug. Unless the plug is out it can't be seen. The other is if the bars did switch sides and the motor drove them into the housing so spline shear off damage happened. Here is a photo of that issue but again the damage would be inside the compensator and not seen. If the bars are bent that might give an indication that has happened.

Posted on: 2013/6/23 10:53

|

|||

|

Howard

|

||||

|

||||

|

Re: Torsion Level again....

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Yes I would think it's something like that. Can the car be driven if I take the motor and compensation unit out? I can't leave the car in the workshop waiting for parts to be sent from USA to Spain).

/Jan

Posted on: 2013/6/23 11:25

|

|||

|

||||

|

Re: Torsion Level again....

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

You can drive the car although depending on how stiff the shocks are and how much weight is in the car the suspension will have a mind of it's own.

It will be free floating so the rear will move up and down to some extent. One time a stop may cause the rear to be up and the next stop it may be down. If the rear is light and always up, some sacks of sand in the trunk may calm it. If the trunk is already heavy not much can help and the rear will be down.

Posted on: 2013/6/23 11:45

|

|||

|

Howard

|

||||

|

||||

|

Re: Torsion Level again....

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Thanks. I'll get back when I've had the car on the lift.

/Jan

Posted on: 2013/6/23 11:51

|

|||

|

||||

|

Re: Torsion Level again....

|

||||

|---|---|---|---|---|

|

Home away from home

|

Jappe,

I went thru this with my 56 Executive and it was caused by a series of problems, loose worm gear in the compensator gear box, bad limit switches, bent connecting rods, all could be fixed. Look closely at the driver's side connecting rod and make sure it is 'in front of' the passenger side connecting rod where they attach to the center 'yoke'.

Posted on: 2013/6/24 20:34

|

|||

|

Bob

IF EVERYTHING IS COMING YOUR WAY ... - - - - - - - - - - - - - - - - - - - - - - - - YOU'RE IN THE WRONG LANE! '56 Executive Touring Sedan |

||||

|

||||

|

Re: Torsion Level again....

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

I've now been under the car and I saw one fix point of the compensator was broken so I did not even bother to take it out. I just have to order a new/rebuilt one I guess :(

I also noticed that the short arm had a little bend.. /Jan

Posted on: 2013/6/26 5:52

|

|||

|

1949 Packard 2265-9 Deluxe Eight Club Sedan

1956 Packard 5647 Clipper Super Hardtop Coupe 1953 Packard 2679 Convertible |

||||

|

||||

|

Re: Torsion Level again....

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Call Mike Dulinski 218-721-4631. Fair, honest and quick.

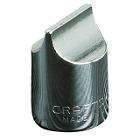

Tell him you need compensator and the two short arms. You will also need this tool to disconnect the arms. Attach file:  (2.84 KB) (2.84 KB)

Posted on: 2013/6/26 8:44

|

|||

|

||||