|

Re: 1940 110 oil filter insyallation

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

You would use a T at the pressure feed off the block. They are 5/16th lines as I recollect. The return should go to a plugged spot on the skirt of the block. The most important thing to know is somewhere on the feed side there must be a flow restriction because only a small portion of the oil can be bypassed off through the filter and the lions share of the oil dedicated to the engine components.

Packard originally used a T fitting that had approximately a 1/16th hole drilled in the filter supply port. I've installed exactly the filter you have on a Chevy 235 6 and soldered up a brass fitting and drilled a 1/16th hole because of low indicated idle oil pressure. Worked fine, no reason you couldn't with installation on the Packard. Best of luck!

Posted on: 2013/9/2 10:47

|

|||

|

||||

|

Re: 1940 110 oil filter insyallation

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

Thanks for the info.I was looking at the recently posted original Packard instructions for installing a filter. On closer inspection , there is a short line going in and out of the block at the base of the crankcase filler tube. The instructions say to remove this line and make no mention of putting it back. This would give me an inlet and outlet separately on the block , without a T ,correct ? The short line appears to be 3/16". This all may be an exercise in futility for now , however , as the bottom of the cannister that the cartridge sits on has rusted out somewhat and I will need to find another one !

Jim

Posted on: 2013/9/2 11:20

|

|||

|

||||

|

Re: 1940 110 oil filter insyallation

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

Correction.

The short line is a 1/4" . Jim

Posted on: 2013/9/2 11:27

|

|||

|

||||

|

Re: 1940 110 oil filter insyallation

|

||||

|---|---|---|---|---|

|

Home away from home

|

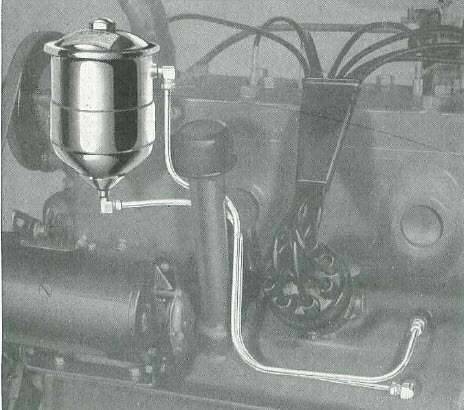

The 40-46 six did not use a T block (see photo below). You'll see a pretty simple installation. However, there is a hidden benefit of using the T block if you don't know how your replacement.

The T block was primarily used for engines with Hydraulic Tappets (like the super 8) in conjunction with a special filter canister that had the letters HT or HYT stamped on the rim of the lid, standing for Hydraulic Tappets, which needed reliable pressure in order to maintain correct function; you never wanted to starve them. Also, those cars with an electric oil pressure sense gauge used the T block to mount the signal sender. Now back to your 40: Your car did not have an electric gauge. The original Packard 40 junior filter canister has a blowoff pressure of 10 psi, which means that as the filter element becomes clogged, it creates backpressure. When this pressure becomes greater than 10 psi, a check valve opens, allowing oil to bypass the element and get on its way back into the engine. This way, the bearings, etc will not be starved due to a dirty filter. Not all filter canister makers used the bypass function, or had the same blowoff pressure. If yours has no bypass and the filter became clogged (which would be really clogged) the filter would block the flow. So, without this, your choice is to be vigilant with your filter changes, or put in the T block with an orifice of sufficiently small size such that it forces some oil will through the filter. Before I had a Packard filter, I had one with no bypass, but chose not to use a T block because I wanted all the oil to go through the filter. I also changed it every year....long before hit the recommended 2000 mile interval. I hope this helps, Pat Attach file:  (26.32 KB) (26.32 KB)

Posted on: 2013/9/2 19:56

|

|||

|

||||

|

Re: 1940 110 oil filter insyallation

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Much better advice provided by Pat. I forgot that the '40 6 had full flow filtration and did not dump back to the crankcase, similar to the 356 prior to the bulletin instructing to drill the crankcase and convert it to bypass. I still run my '40 356 in full filtration mode, and like the idea very much. (I'll have to look at my brothers 110 next time I have the chance) I would heed Pat's explanation about having an internal filter bypass feature if plumed this way, for no other reason than oil starving on a very cold morning where oil might not flow through the filter element as easy as warmed up. Also, if not running in bypass mode, do not run a restriction of any kind.

Jim

Posted on: 2013/9/2 21:33

|

|||

|

||||

|

Re: 1940 110 oil filter insyallation

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

Thanks guys. I just completed the installation and it works fine (just make sure the cap is on TIGHT !).There is no room for a T on this car. The fittings are right against the crankcase filler tube, unlike the picture that Pat posted. The filter is available through Fram , part # C134PL. Thanks again for the help.

Posted on: 2013/9/5 13:58

|

|||

|

1940 110 Business Coupe (1388)

|

||||

|

||||

|

Re: 1940 110 oil filter insyallation

|

||||

|---|---|---|---|---|

|

Home away from home

|

Glad it work. Amen to the cap being tight...nothing like pumping oil out of the leak while you are darting to shut down the engine.

On a related note: as you replace the filter in the future, you may want to research a few different types whose only difference is the cap seal. I've noticed you can buy filter elements of exact same dimensions with different diameter seals. Happy Trails, Pat

Posted on: 2013/9/6 11:16

|

|||

|

||||

|

Re: 1940 110 oil filter insyallation

|

||||

|---|---|---|---|---|

|

Home away from home

|

Not sure but I think you plumbed it backwards. If you look at the photo of the factory installation and carefully follow the tubes, you'll see that the upper one goes to the pressure feed while the lower goes back to the crankcase but it appears that your is the other way around. Don't know if it makes any difference but I thought I would point it out.

Posted on: 2018/10/15 18:55

|

|||

|

All generalities are false.

Once I thought I was wrong but I was mistaken. Don Pierson Packard / IMPERIAL page CA DMV Licensed Vehicle VIN Verification 1951 Henney-Packard 3-Door Long Wheelbase Air Force Ambulance The 1951 Henney-Packard is For Sale! 1954 Packard Patrician 1954 Packard Patrician Parts Car 1956 Clipper Custom Sedan |

||||

|

||||

|

Re: 1940 110 oil filter insyallation

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Not sure but I think you plumbed it backwards.

Depends on the canister but I agree that with todays filter element the side inlet would seem to be better if the canister can do it. Packard had several variations to the plumbing and 2 different filter canisters prewar due to the lifter starving issue. Many if not all of the prewar canisters had the inlet at the bottom and outlet on the side. First version filters with the bottom inlet and all lifter oil thru the filter would clog starving the lifters. They revised plumbing without much effect then went with the revised plumbing and a second version filter canister which had a blow off valve to bypass the filter if it clogged. Final version kept that second filter since it still entered at the bottom but also went to the bypass plumbing with the drilled hole to dump back into the crankcase. There were also different interval recommendations for changing the element. Canister plumbing was reversed postwar to the inlet on the side and outlet at the bottom and they went back to the first version filter with no valve. I guess the blowoff valve wasn't needed when they revised things to use the large outer circumference of the filter element to collect dirt rather than clogging up the small narrow inner core. IMO, that is the better (but not correct) plumbing method for prewars too.

Posted on: 2018/10/15 19:35

|

|||

|

Howard

|

||||

|

||||