|

Re: 1934 1100 Timing

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Far too much to explain than I care to type, PM me your phone and a time to call. But for starters:

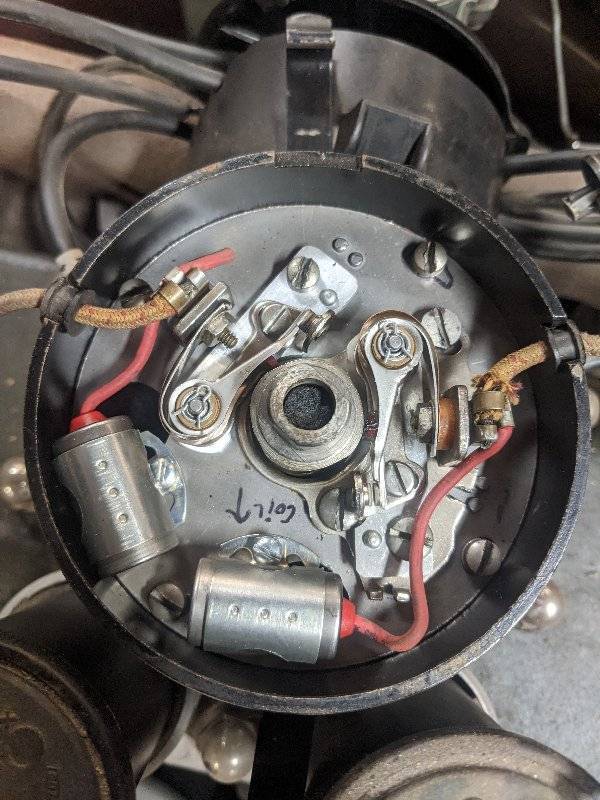

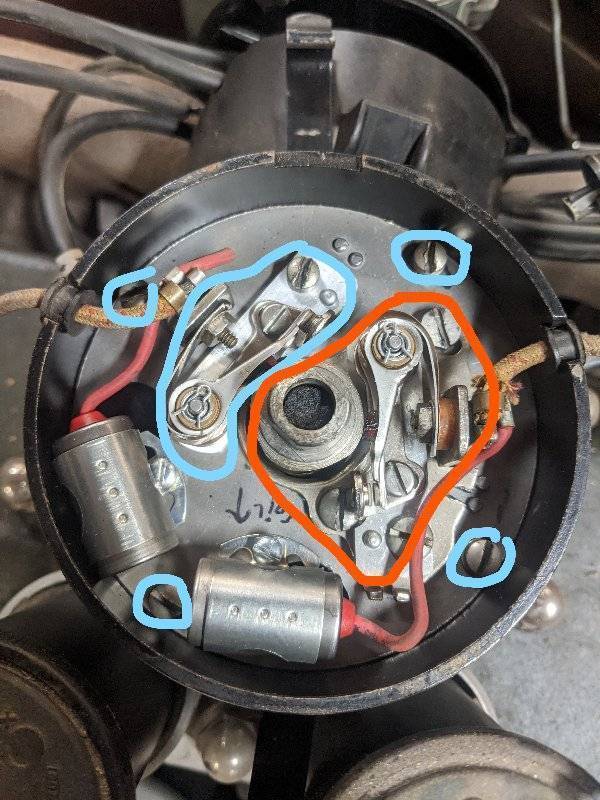

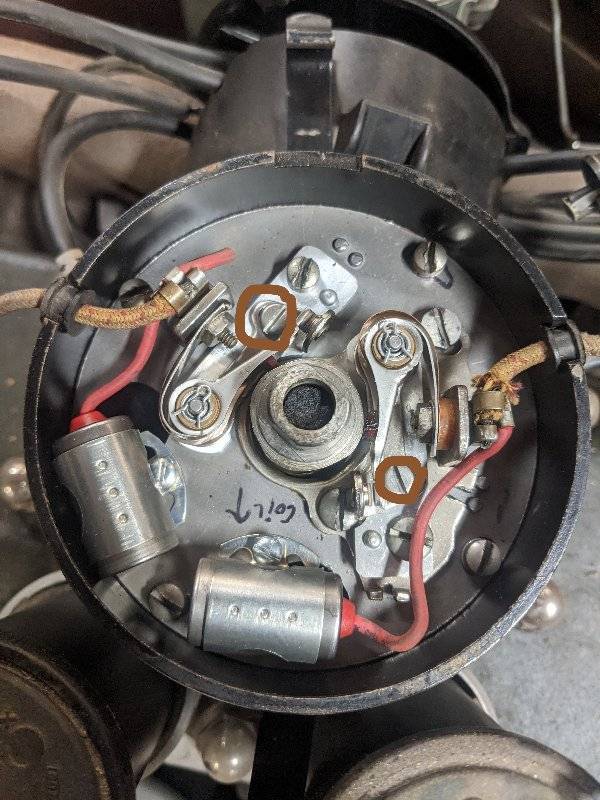

- #6 timing marks on the front pulley are for when the light is on cylinder 6. There are a separate set of timing marks for #1. Each sets timing for 4 cylinders, just keep in mind that you have what amounts to two separate 4-cylinder ignition systems coexisting in a single distributor body, only used 1933-34 on Eights and Super Eights. Fixed points fire 1, 2, 7 and 8; adjustable points fire 3, 4, 5 and 6. - Resistance measurements are not a reliable way to test a coil, nearly useless. Either borrow a coil tester, or test by substituting a known good coil such as a NAPA generic. - your distributor has a 4-lobe cam so if you wish to use a dwell meter, set dwell as for a 4-cylinder motor not an 8. Dwell was not in use in that era, I set the gap per the specs. -You could time #1 by rotating the distributor body, lock it down and time #6 by rotating the set of points that are on a separate moveable breaker plate segment. But its trial and error and very little room under the hood to work. So simplist is to do it the way Packard recommended, remove the distributor and synchronize the two sets of pints to fire at the proper interval on a distributor test machine, or make a simple tool like the NorthEast synchronizer tool pictured in the service letters. You could also read my writeup on setting up this distributor on the Packard Club forum. - With your current timing of 4 and 3 degrees, though not exactly on spec, is close enough, engine should perform well and your problem is almost certainly elsewhere. - Not that it should matter, but your distributor has been modified to use modern Chrysler points, the OEM NorthEast points are beefier and much longer lasting, but alas have been hard to source even 20 years ago. Also though it shouldn't matter if properly selected, you have aftermarket coils. - I'd suspect your engine performance problem is due to a vacuum leak, perhaps the brake booster system, chassis lubricator, vacuum booster pump, wipers or even (unlikely) the Stromberg automatic choke. Most likely are the brake booster cylinder or brake booster selector valve, especially if the still are using the original treated paper diaphragms. Classic & Exotic has replacements in neoprene. Have you checked the intake manifold to block studs and nuts for tightness? Intake manifold gaskets for leakage? - The brass ring inside your distributor for the outer rotor carbon brush looks suspect. It looks granular or sandblasted while it should be bright and polished smooth to allow the 2nd carbon brush to make good contact. Id think the rough finish would rapidly wear the brush so check both rotor brushes and springs. - The 4 screws equally spaced at the outer perimeter of the breaker plate hold the plate in place, you do NOT use them to adjust the timing of the points on the small moveable segment breaker plate, it has its own hold down screws for that purpose. - To my knowledge Packard did not specify an idle speed in RPM, mine idles quite comfortably at about 375 rpm. At a compression ratio of 6:1, you should expect a compression test pressure of about 100 lbs though it depends on altitude above sea level, carbon buildup, and the particulars of how you conduct the test. Check this:packardclub.org/forum/viewtopic.php?f=14&t=864 EDIT: missed your note that point set #1 was firing at 4 deg BTDC and point set #2 at 3 deg. Ignore my comments about synchronizing the points, they are already quite adequately synchronized but you might set timing closer to 6 deg. BTDC.

Posted on: 2020/11/13 19:01

|

|||

|

||||

|

Re: 1934 1100 Timing

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Ken,

If you talked to Owen I am sure he told you to check the distributor advance to make sure it is working properly. The distributor advance is the most neglected part of the engine and one of the most important to proper running, IMO. If no advance the engine will bog down and be all in at about 50 mph. FYI, The points in the distributor are NAPA CS720 and the condensor is NAPA AL869. John

Posted on: 2020/11/16 10:18

|

|||

|

||||

|

Re: 1934 1100 Timing

|

||||

|---|---|---|---|---|

|

Home away from home

|

Interesting NOTE for u originality freaks. The Dist. photos show original Primary Wires and thus colors.

TAN with a RED TRACER. Did they come in more than one color??? Years back i played with a MARMON 16 which had Lacquered Steel Gray Primary wires that matched the Laq. Steel Gray Spark Plug wires.

Posted on: 2020/11/19 10:52

|

|||

|

||||

|

Re: 1934 1100 Timing

|

||||

|---|---|---|---|---|

|

Quite a regular

|

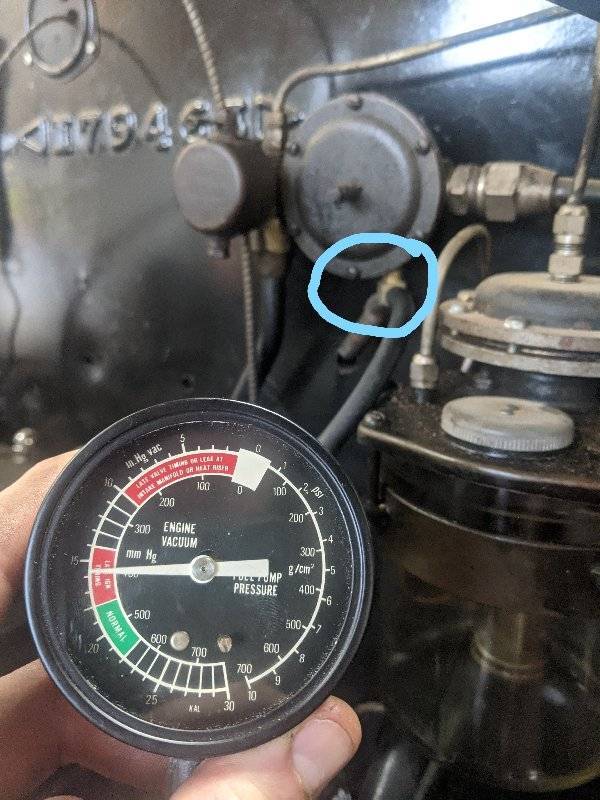

Owen, I too would like to check the timing on my 1100 and am looking at this exchange. In the photos provided it looks like where he is looking at the timing marks is on the left side of the engine and that there is a bracket attached to those two bolts on the front of the engine that is used as the index point for the timing. My car does not have that bracket, which I am assuming is a problem? Any suggestions?

Thanks, Bill

Posted on: 2023/6/23 15:26

|

|||

|

||||

|

Re: 1934 1100 Timing

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Are you saying you have the two sets of marks on the vibration damper but are missing the pointer which would be attached to the timing chain cover?

If so, the easiest course of action will be to locate and install a replacement pointer. The 1933-36 parts list will tell you which years and models have the correct pointer. I could provide a photo from my spare motor. Alternatively if you are unable to source a pointer, you could pull the cylinder head and set up a dial indicator on #1 piston to find TDC.

Posted on: 2023/6/23 17:28

|

|||

|

||||

|

Re: 1934 1100 Timing

|

||||

|---|---|---|---|---|

|

Quite a regular

|

If I am interpreting the picture correctly, I'm looking in from the left side. Is that correct? If so, I do not have said bracket, nor for that matter do I see the timing marks on what I assume is the vibration damper. Also, is the 1933-1936 parts list a document that is available somewhere?

Posted on: 2023/6/23 19:18

|

|||

|

||||

|

Re: 1934 1100 Timing

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Yes, the pointer and vibration damper index markings are observed from the driver's side of the motor. If you can't find any marks on the damper, perhaps they are concealed by a buildup of paint or rust. Try a good cleaning and look again. The photo above looking down on the marks and pointer is an accurate presentation.

The 1933-36 Eight/Super Eight parts list is available as a hardcopy reprint from the Packard Club and also available digitally on this site in the Literature Archive.

Posted on: 2023/6/23 19:24

|

|||

|

||||

(230.34 KB)

(230.34 KB)