|

Re: 282 head unknown hole size

|

||||

|---|---|---|---|---|

|

Home away from home

|

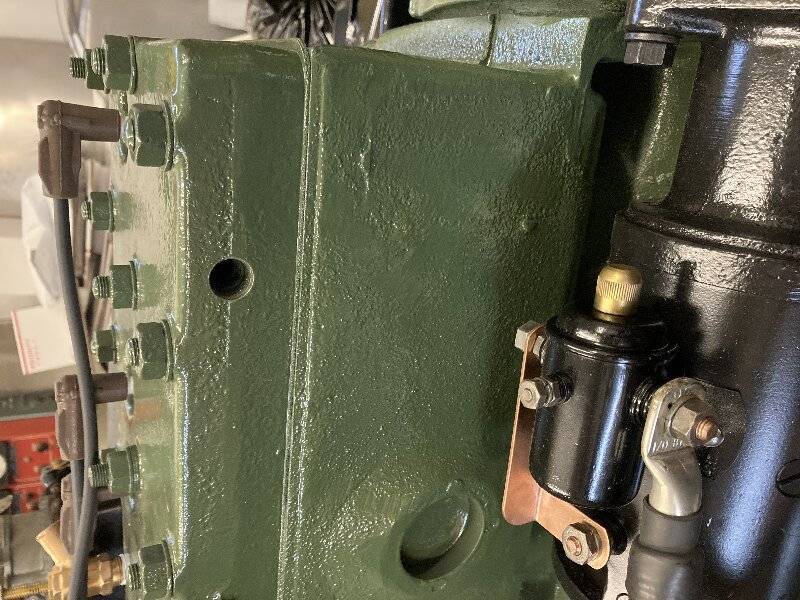

Good Morning...It seems to me that hole is for your engine heat sensor...but then, again, I have been wrong at least as often as I have been right! Ernie in Arizona

Posted on: 2021/1/31 13:56

|

|||

|

Caretaker of the 1949-288 Deluxe Touring Sedan

'Miss Prudence' and the 1931 Model A Ford Tudor 'Miss Princess'

|

||||

|

||||

|

Re: 282 head unknown hole size

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

I think you are correct - That makes perfect sense!

That's what happens when it takes over 10 years to get this far. the memory isn't what it use to be. Thanks for the help

Posted on: 2021/1/31 14:18

|

|||

|

||||

|

Re: 282 head unknown hole size

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

And if I remember correctly the temp sensor bulb hole thread is 5/8-18 on that head. The 3/8 NPT pipe fitting is correct for the hole in the top center of the head or on the water pump where the nipples for heater hot water connections are located.

Posted on: 2021/1/31 14:29

|

|||

|

Howard

|

||||

|

||||

|

Re: 282 head unknown hole size

|

||||

|---|---|---|---|---|

|

Home away from home

|

Jerry;

I thought most temperature gauges before the war were mechanical, and inserted a bulb into the engine, in the case of Packard, in the aft portion of the cylinder head. The bulb would typically have a sealing ring or gasket to inhibit water leaks placed between the engine casting and the bulb flange. The threaded gland nut would ‘push’ onto the bulb’s flange and subsequently compress the sealing ring/gasket. Ok if that’s the design that Packard used before the advent of electric water temperature gauges, then the gland nut threads would not be tapered, because the intimate contact between the bulb and nut would not be guaranteed with tapered threads. This business of using mechanical temperature gauges extended to at least the mid 50’s. As a young man I owned a ’55 Chevy, and that car surely had a mechanical gauge. The shop manual for that car talks about an ‘O’ ring . . . no mention of material . . . to seal the bulb . . . I just looked it up. If the car is/was equipped with a mechanical temperature my vote would be the threads are not tapered, and therefore not NPT. 3/8 pipe would have 18 TPI with a diameter about 0.675 (remember it’s tapered), which would be something like 0.050 larger than Howard’s recommendation of 5/8 X 18 UNF. dp

Posted on: 2021/1/31 17:56

|

|||

|

||||

|

Re: 282 head unknown hole size

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

I found a 5/8" 18 bolt and it threaded into the head perfectly, I need to dig through my boxes and see if any of my temperature gauges are complete with sending units

All great info!

Posted on: 2021/1/31 19:37

|

|||

|

||||

|

Re: 282 head unknown hole size

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

42 would have a sensing bulb connected to a length of spiral wrapped copper tubing going to the gauge. The sealing surface is between the machined bottom of the threaded hole and a flange on the sensing bulb pressed tightly together by the nut holding the unit to the head. No electrical is involved so not too much worry about grounding issues but it would pay to ensure there is no pitting or rusted areas at the back of the hole where the flange could not tightly seal against.

Some modern universal gauges come with adapter nuts for various threaded holes and on the one I used I found the nut or adapter was too short to press the bulb against the rear of the fairly deep hole. In that instance I used an O ring rated for higher temperatures on the bulb between the flange and hole end to make the seal.

Posted on: 2021/1/31 19:47

|

|||

|

Howard

|

||||

|

||||

image.jpg (353.93 KB)

image.jpg (353.93 KB)