|

Re: V8 Engine Building

|

||||

|---|---|---|---|---|

|

Home away from home

|

I heard from Ross and this is fine.

I replaced one fairly pitted piston with an NOS. I had some trouble getting the pin in. The manual says that about a 100F difference is required for a slip fit. This is true, but the metals quickly heat each other and match temperature. Ended up having to tap it in some while it was still cold. Edit: To clarify, I used dry ice to cool the pin, instead of boiling the piston. Anyway, lubed the bushing and it should be good now.

Posted on: 2024/9/8 9:09

|

|||

|

1955 400 | Registry | Project Blog

1955 Clipper Deluxe | Registry | Project Blog 1955 Clipper Super Panama | Registry Email (Parts/service inquiries only, please. Post all questions on the forum.) service@ultramatic.info |

||||

|

||||

|

Re: V8 Engine Building

|

||||

|---|---|---|---|---|

|

Home away from home

|

Some updates. I got the rest of the pistons in last weekend as well as some various other things. The videos from Uncle Tony's Garage are helpful with this. Main difference is I don't like pounding the pistons in with a cheap ring compressor. The most annoying, but also hardest to break, rings are the oil rings at the bottom. They can easily slip under the ring compressor if it's not seated well or you aren't careful. One those are in, the other two go in with little drama, as long as you have the bevel at the top of each cylinder. So I like to use little taps as big hits can shove the ring compressor into the cylinder then you gotta pull it out.

Side note, I was a bit worried about breaking the piston rings when installing, but it wasn't bad. The most difficult is pretty much always gonna be the middle ring, but it went well overall. I will be doing the heads this weekend. The head gaskets need Permatex 80697 Copper Spray Gasket applied to both sides. For the oil pan gasket, it's easy to see in the photo that the gasket does not line up with the hole. I was instructed to bend the tab upward 90° to rest against the half circle seal. The half circle itself sits below flush on the rear of the engine. Attach file:  20240930_192657.jpg (981.71 KB) 20240930_192657.jpg (981.71 KB)  20240930_192613.jpg (421.67 KB) 20240930_192613.jpg (421.67 KB)  Resized_20240930_183619.jpeg (41.21 KB) Resized_20240930_183619.jpeg (41.21 KB)

Posted on: 2024/10/5 9:02

|

|||

|

1955 400 | Registry | Project Blog

1955 Clipper Deluxe | Registry | Project Blog 1955 Clipper Super Panama | Registry Email (Parts/service inquiries only, please. Post all questions on the forum.) service@ultramatic.info |

||||

|

||||

|

Re: V8 Engine Building

|

||||

|---|---|---|---|---|

|

Home away from home

|

Spud.

That end of gasket goes in the main. Then the other gasket goes on top I use the spring steel type ring compressor. Bit .. use a lot of oil

Posted on: 2024/10/5 16:13

|

|||

|

Riki

|

||||

|

||||

|

Re: V8 Engine Building

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Too late lol. Quote:

On the front side that's what I did. But you can't do it in the back since it's recessed in. No way it would seal properly I think. I used a film of engine prelubricant to help them in. Cylinders prelubed with fogging oil. Then once they were all in I rotated the engine upside down and poured some 10W40 in each cylinder then rotated it through a few turns then flipped it back over, to make sure there's good lubrication on the walls. Service manual says to dip each whole piston in oil before install, which I did not do. Side note I noticed someone already replaced the engine rings in the past as they were not original. But the cross hatching was worn off the walls and the rings were stuck, hence the service I did.

Posted on: 2024/10/5 20:57

|

|||

|

1955 400 | Registry | Project Blog

1955 Clipper Deluxe | Registry | Project Blog 1955 Clipper Super Panama | Registry Email (Parts/service inquiries only, please. Post all questions on the forum.) service@ultramatic.info |

||||

|

||||

|

Re: V8 Engine Building

|

||||

|---|---|---|---|---|

|

Home away from home

|

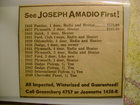

Never forget the critical parts!

Posted on: 2024/10/7 17:55

|

|||

|

1955 400 | Registry | Project Blog

1955 Clipper Deluxe | Registry | Project Blog 1955 Clipper Super Panama | Registry Email (Parts/service inquiries only, please. Post all questions on the forum.) service@ultramatic.info |

||||

|

||||

|

Re: V8 Engine Building

|

||||

|---|---|---|---|---|

|

Home away from home

|

Entire mechanical system is back together. Next is cooling system and distributor. Unfortunately one of the exhaust bolts is completely stripped out since before I got the engine. So I just didn't use that bolt. Probably will be OK since the gasket has good compression, but we will see I guess. I could probably tap the hole in the block but I would have to oversize the manifold hole and counterbore, so there's no easy way. It may also already be too messed up to Helicoil.

The fuel pump hose I got from MM is not the factory size. I assume my pump has the wrong fitting as it's the Hash style. Gotta find an adapter. Lifter baffle needs to go back in and one oil line from the filter. By the way, what's the point of said baffle? Also how can I torque-tighten the pulley bolt properly? Was thinking of removing 2 screws from the flex plate and mounting something for leverage. Well, gotta get to bed as I am driving to Hershey bright and early tomorrow morning, 4 hour drive.

Posted on: 2024/10/7 22:50

|

|||

|

1955 400 | Registry | Project Blog

1955 Clipper Deluxe | Registry | Project Blog 1955 Clipper Super Panama | Registry Email (Parts/service inquiries only, please. Post all questions on the forum.) service@ultramatic.info |

||||

|

||||

|

Re: V8 Engine Building

|

||||

|---|---|---|---|---|

|

Home away from home

|

I usually use a crank counter balance hole.

But your pan is on. Do your plan. Or. If your damper has deep balance holes use one against frame when engine is in .

Posted on: 2024/10/8 4:59

|

|||

|

Riki

|

||||

|

||||

|

Re: V8 Engine Building

|

||||

|---|---|---|---|---|

|

Home away from home

|

why not helicoil the stripped manifold bolt hole. I hate the sound of a leaking exhaust connection . when engine out of car not hard job to do repair just my personel feeling

Posted on: 2024/10/8 11:15

|

|||

|

||||

|

Re: V8 Engine Building

|

||||

|---|---|---|---|---|

|

Home away from home

|

Are you going to paint it while it's out?

Posted on: 2024/10/8 16:34

|

|||

|

||||