|

Re: T/L universal ball joints at gear box lever!

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

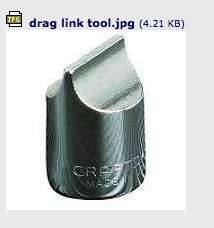

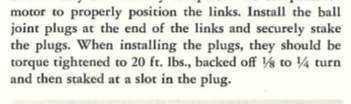

If you are using the socket tool shown then the problem is someone maybe was a bit ambitious in the staking operation. As you can see from the instructions, they were to be staked at the slot and only way I know to do that would probably mess up the threads. If that's the case, I don't know of any way other than some kind of wedging pressure against the back of socket wrench to keep the socket in the slot, longer lever or brute force and perseverance.

Attach file:  (6.42 KB) (6.42 KB)  (7.71 KB) (7.71 KB)

Posted on: 2009/9/4 19:38

|

|||

|

||||

|

Re: T/L universal ball joints at gear box lever!

|

||||

|---|---|---|---|---|

|

Home away from home

|

That is the one. I also read that about staking the plug, after torqueing and then backing off 1/6th or 1/4 turn. I also figured that maybe the problem and checked for obvious signs of staking or visible signs of damaage at the edge of the plug, but found none. I did manage to back out and turn two of the plugs,maybe a oouple of threads. The problem is keepping enough pressure on the ratchet or breaking bar at the socket head while keeping the tool and plug squared up with each other while turning the wrench. Also the car is not on a lift but tires wheel ramps, with jackstands under the four corners of the frame, and one jackstand under the frame at either side near the xframe. Very Safe, but doesn't allow for much working space or room for leverage.

I did try using a pry bar of sorts to help put more pressure on the wrench head but, doesn't work well with the ratchet head. One major problem is when you put a lot of pressure on the wrench to keep the blade in the slot, it also requires more torgue to turn the wrench because of the additional pressure on the threads. Another problem is, with the car being level, ends of both of the bars are only about 3" from the frame rails which severely limits ones options of tools.

Posted on: 2009/9/4 22:50

|

|||

|

||||

|

Re: T/L universal ball joints at gear box lever!

|

||||

|---|---|---|---|---|

|

Home away from home

|

The plugs are hard to remove since they were staked at the factory as noted in the service procedure. I have taken them out with the same type of socket that you are using and it does take quite a bit of force. Don't know of any other way to do it.

Posted on: 2009/9/5 0:19

|

|||

|

||||

|

Re: T/L universal ball joints at gear box lever!

|

||||

|---|---|---|---|---|

|

Webmaster

|

I've never seen an impact version of a drag link tool socket, but if they made one then that would make removing it pretty easy.

Posted on: 2009/9/5 7:59

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: T/L universal ball joints at gear box lever!

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Memory says I used a breaker bar and wedged some wood against the frame to make a tight fit in order to get the plugs started past the staked part. It was a pain to get the first few turns completed but after that I could use a ratchet. That is the proper tool - I used to tighten drag links with it.

Posted on: 2009/9/5 9:24

|

|||

|

||||

|

Re: T/L universal ball joints at gear box lever!

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Cli55er initially modified a small pry bar to get his out. Maybe something like that would work if you can wedge a 2x4 between it and the frame for leverage since there wouldn't be as much friction. Check his tool out in post 173 of his blog.packardinfo.com/xoops/html/modules/newbb ... ic.php?post_id=15945#forumpost15945

Posted on: 2009/9/5 9:56

|

|||

|

||||

|

Re: T/L universal ball joints at gear box lever!

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks everyone, I will keep on grunting a lot and cussing (just a little), and will hopefully succeed.

HH56, Cli55er did have a good idea there and it worked for him, as they necessity is the mother of invention. unfortunately I don't believe I have the room to maneuver any bigger than my ratchet or breaker bar. I'll post my results.

Posted on: 2009/9/5 10:44

|

|||

|

||||

|

Re: T/L universal ball joints at gear box lever!

|

||||

|---|---|---|---|---|

|

Home away from home

|

I did get the screwed plug out the ball joint passenger side this moorning but, it flew out when i got that last thread and made one heck of a pop as it came out. That would seem to indicate there is still load on the bars.I do have the T/L levers 1/2" off center towards the center of the car.

I have the car sitting on it's wheels with no load on the 4 jack stands under the main frame rails nor on the jack under the front of the car at the motor cross member. The ? is this, should I take the load off the body of the frame by placing jack stands under the bumpers. Or should I reposition the levers. I did see a note stating the Packard book was wrong and the levers should be 1/2" away from the center, and towards the sides of the car. I also noted he had the body off the frame.

Posted on: 2009/9/6 10:25

|

|||

|

||||

|

Re: T/L universal ball joints at gear box lever!

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I think since you have one of the screws out now, that positioning the car would be easier. If your leveler still works, you could try that but then overshoot may be an issue as it coasts to a stop.

Unless something has really sagged, it should be fairly easy, keeping the wheels as they are, to raise one end of frame or the other with a jack a few inches and see which takes the load off. If lever is wanting to go to the frame, then would try raising the front first. There should be a point where no load on the loosened lever will be obvious. If that doesn't work and it still wants to go more toward frame, then would put a small block between frame and lever to prevent going any further, just tap the motor until block tight and then loosen.

Posted on: 2009/9/6 11:06

|

|||

|

||||