|

Re: '55-'56 A/C Systems

|

||||

|---|---|---|---|---|

|

Home away from home

|

"If there is a spacer between the two pulleys, then the outer portion is no longer an interference fit and thus is un-supported. Am concerned the sheet metal might eventually fatigue."

Then use a spacer of the correct thickness. REGARDLESS, if metal fatigue would be an issue by not being supported then we really have a BIG PROBLEM with the water pump pulley. NO support there!!!!

Posted on: 2007/10/23 22:47

|

|||

|

||||

|

Re: '55-'56 A/C Systems

|

||||

|---|---|---|---|---|

|

Home away from home

|

Jack, the spacer goes in there because the two pulleys won't bottom out together when assembled. Hence the spacer (I used a couple of washers to dial it in) to make it a solid unit. It's been in my Pat for over a year, at speeds over 90 miles an hour several times, with all the load from the supercharger on it, since I don't have the spring loaded idler like the Avanti originally had.

Posted on: 2007/10/24 2:35

|

|||

|

||||

|

Re: '55-'56 A/C Systems

|

||||

|---|---|---|---|---|

|

Just popping in

|

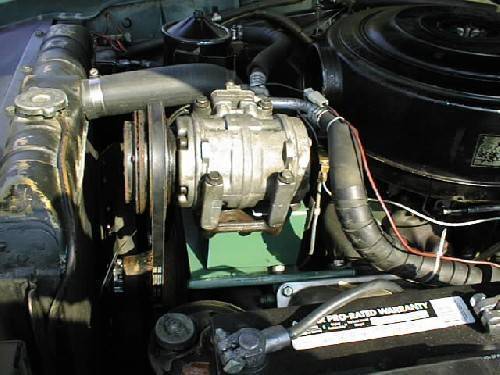

Id be interested in purchasing a bracket with pulleys with sanden compressor, as I have spent quite a bit of time thinking of a way to do this for my 56 Clipper

Posted on: 2008/3/17 23:07

|

|||

|

||||

|

Re: '55-'56 A/C Systems

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

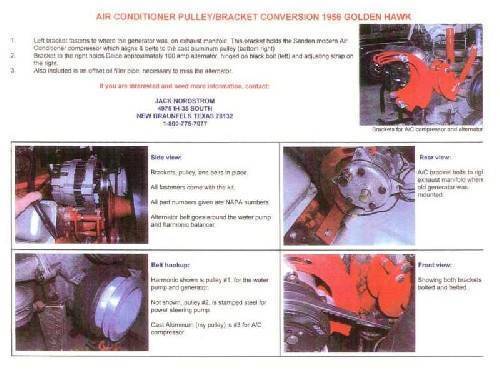

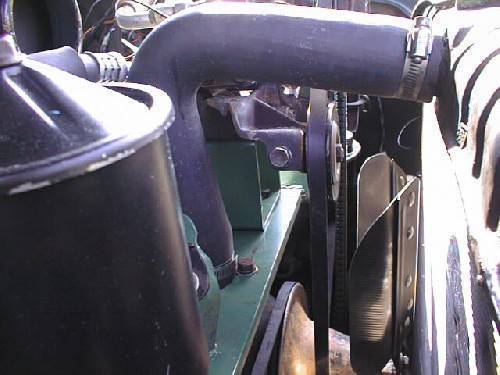

Jack Nordstrom mfgs & advertises occasionally in PAC publication the original Packard type correct diameter pulley & longer bolt if the extra PS pulley setup mentioned above doesn't meet your needs.

He also has a bracket for the Sanden but looking at his (which is made for the Hawk), it seems to be a bit over the top for Packards. Maybe its the way his is painted, but my 2 cents says something made along the lines of the original and in the same location would be a better choice-just make the aftermarket so the thermostat can be changed and isn't covered if possible. His picts can be viewed at the GoldenHawk page in the options, Technical, AC addition.1956goldenhawk.com/

Posted on: 2008/3/18 9:12

|

|||

|

||||

|

Re: '55-'56 A/C Systems

|

||||

|---|---|---|---|---|

|

Just popping in

|

Hello All . . .

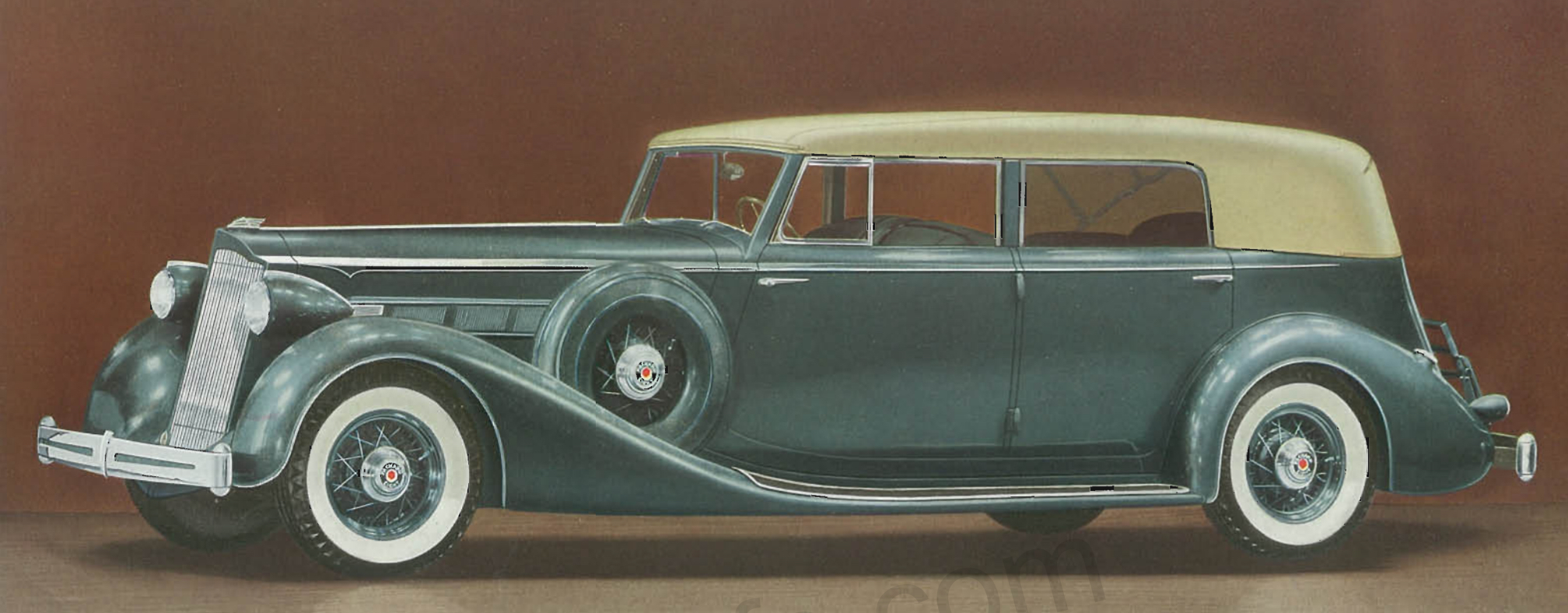

Jack Nordstrom has asked that I provide you folks with a scan of his product page. It is located at this link: http://www.comalnet.com/Packard/ I have included the scanned file as an attachment as well. Thank you very much. CTODWC

Posted on: 2008/4/5 9:39

|

|||

|

||||

|

Re: '55-'56 A/C Systems

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Thanks for posting where all can see the setup. As I mentioned in an earlier post, for my 2 cents I think the pulley is a good idea because it's correct size so less danger of over revving the compressor & also appears to use a wider belt. Am not convinced on bracket however--mostly because it requires moving/replacing generator. I believe there was an earlier post & picture of a possibly aftermarket type bracket that mounted in original Packard location. Believe it was by Mr Vines but not certain. (The way we mix our post subjects, didn't find it doing a quick search.) Anyway, if someone were to make that type available, it seems to me a better way to go -even if it requires moving oil filter-since we have plenty of hood clearance and it keeps things in stock locations.

Posted on: 2008/4/5 11:02

|

|||

|

||||

|

Re: '55-'56 A/C Systems

|

||||

|---|---|---|---|---|

|

Home away from home

|

All u need is flat steel stock, and engine mount, cheap arc welder and willing to get friendly with hack saw and file and grinder.

I used pump and bracket and pulley amd condenser from 84'ish Toyota.

Posted on: 2008/4/8 21:32

|

|||

|

||||

|

Re: '55-'56 A/C Systems

|

||||

|---|---|---|---|---|

|

Home away from home

|

Seems many of the aftermarket brackets back then were also made of fabbed flat stock. The only "downside" to making up your own brackets is addressing alignment and "squareness" which a properly designed and jig welded aftermarket system (theoretically) avoids.

Posted on: 2009/9/7 0:15

|

|||

|

||||

|

Re: '55-'56 A/C Systems

|

||||

|---|---|---|---|---|

|

Home away from home

|

"The only "downside" to making up your own brackets is addressing alignment and "squareness" which a properly designed and jig welded aftermarket system (theoretically) avoids"

TRue IF one is going into PRODUCTION of such parts or any part for that matter. In my case i only needed to make ONE. No special tools or jigs required. Just a 4 foot precision LS Starret steel scale, some machinist squares and an arc welder, and a spare engine for mockup. My home made bracket has worked just fine for 8 years and over 20K miles. Belt never replaced and still looks good. IT works!. Why do i need to make any production tooling for it??? No alignment problems that i can determine. My bracket is perhaps a bit crude in appearence compared to 'production' made brackets. But it's designed and fits just like the OEM packard bracket. Just not quite as pretty. I want cool air in the car. Not a dash plack.

Posted on: 2009/9/7 10:40

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

(53.06 KB)

(53.06 KB)