|

Re: All wiring nominal and TL not working

|

||||

|---|---|---|---|---|

|

Home away from home

|

Step #6 starts by removing the limit switch / solenoid assembly. Mine doesn't have one, my limit switches are in the compensator gear housing and my solenoids are in the dtivers side fender well. Next it says to remove the link outer cap screws. These are under load and won't they snap free at the last moment? My car is in my garage with little room to operate. I don't think I want to tackle this job myself.

Posted on: 2011/5/21 15:35

|

|||

|

Bob

IF EVERYTHING IS COMING YOUR WAY ... - - - - - - - - - - - - - - - - - - - - - - - - YOU'RE IN THE WRONG LANE! '56 Executive Touring Sedan |

||||

|

||||

|

Re: All wiring nominal and TL not working

|

||||

|---|---|---|---|---|

|

Home away from home

|

Howard, I have read that procedure before and it always scared the bejeebers out of me. The possibility of finger loss is too high imho.

What I prefer is to remove the motor--its just two bolts--and then turn the input shaft stub with a screwdriver or improvised tool. It takes a long time but so does rehabilitation. But before that: It is actually very rare that the gearbox jams up utterly. I would suggest getting a hot battery and two jumper cables. Little wires will not do. Ground the case to the negative post and then try bringing power directly to either of the motor terminals. Only for a moment to get it going so there is little chance of frying it.

Posted on: 2011/5/21 16:14

|

|||

|

||||

|

Re: All wiring nominal and TL not working

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Ross, I agree but sure don't want to see anything torched. Those could also part with great authority when cut if not done carefully. That procedure can be done but absolutely does require extensions and finesse when the last bolts are near. Any one uncomfortable doing it, the screwdriver is a for sure option. With something like 30,000:1 ratio, will require a lot of turning to get them back at least a quarter to third before the load is off. I believe he is using decent wire but a good point on the jumper cable. Just don't want to take a chance if close to center or hit center already to have another few parts to add to the pile of sheared off arm and bent lever & bar assys out there..

Posted on: 2011/5/21 16:24

|

|||

|

Howard

|

||||

|

||||

|

Re: All wiring nominal and TL not working

|

||||

|---|---|---|---|---|

|

Home away from home

|

At this point i see absolutely NO reason whatsoever to remove ANY of the rods or gearbox.

Ross gives excellent advice above. Remove the MOTOR ONLY. Use a 7/16 or maybe it's a 1/2 " bolt with a hexhead on it. Drill the bolt body for a roll pin. Place the tool in the end of the compensator drive shaft and spin it with a ratchet or a drill motor. At this point there is absolutely no reason to torch or disassemble any links or joints. Not unless there is something i missed thru all of this. EDIT: I can provide a pic of the tool described above. I made one for mine. IT WORKS! IT's EASY!!

Posted on: 2011/5/21 16:41

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: All wiring nominal and TL not working

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

At this point, whatever works. Am a little concerned nothing happened when trying the motor unless the wire was too small. If everything factory was disconnected from the motor except extra battery wire to one terminal, it should have at least given a grunt or three and tried unless it is jammed somehow.

Whatever the method, just avoid this result. There are a couple more like it posted by others in various threads. Like Randy, I'll try and bow out and let the real mechanics in the bunch offer the suggestions. Attach file:  (13.77 KB) (13.77 KB)

Posted on: 2011/5/21 17:03

|

|||

|

Howard

|

||||

|

||||

|

Re: All wiring nominal and TL not working

|

||||

|---|---|---|---|---|

|

Home away from home

|

PackardV8,

Can you post a picture of the tool you made to turn the compensator shaft with a drill or a ratchet? I have tried every thing that I can thonk of to un-bind this retched TL. Again the only thing I can think of doing is cutting the rods.

Posted on: 2011/5/21 19:31

|

|||

|

Bob

IF EVERYTHING IS COMING YOUR WAY ... - - - - - - - - - - - - - - - - - - - - - - - - YOU'RE IN THE WRONG LANE! '56 Executive Touring Sedan |

||||

|

||||

|

Re: All wiring nominal and TL not working

|

||||

|---|---|---|---|---|

|

Home away from home

|

Here are some pics of the mess, taken from drivers side under the car...

Posted on: 2011/5/21 19:56

|

|||

|

Bob

IF EVERYTHING IS COMING YOUR WAY ... - - - - - - - - - - - - - - - - - - - - - - - - YOU'RE IN THE WRONG LANE! '56 Executive Touring Sedan |

||||

|

||||

|

Re: All wiring nominal and TL not working

|

||||

|---|---|---|---|---|

|

Home away from home

|

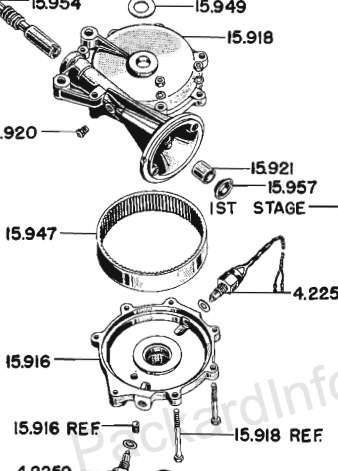

Here it is. NOTE that u do NOT need one this fancy unless u plan to run with TL MOTOR removed.

Get some 1/2" round stock and a 13/64 roll pin. Roll pin size coould be a little larger maybe. U'll have to check the slot width when u get the motor off. 13/64 roll pin worked just fine for me tho. Drill the 1/2" round stock 5/8" from the end for the roll pin. Drive in the roll pin. Mite want to choose a better bolt head configuration to suit a drill motor chuck. AS HH56 indicates turning by hand is EXTREMELY slow. A= 5/8". Z= 3/4". To use strictly as a tool do not need spring on end nor threaded protion that spring is screwed onto. My particular tool was made from a lawn mower wheel/axle bolt. But it was also special for allowing operation of car withOUT TL motor.

Posted on: 2011/5/21 21:36

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: All wiring nominal and TL not working

|

||||

|---|---|---|---|---|

|

Home away from home

|

PackardV8 beat me to it, but here are some photos of the T/L unit that might make things more clear. Removing the motor from the gearbox is simple and safe - just undo the 2 thru bolts.

Posted on: 2011/5/21 21:52

|

|||

|

||||