|

Re: Rear end seals

|

||||

|---|---|---|---|---|

|

Home away from home

|

My plan was to wrap a thick rag around the pinion, double duct tape it, and the sandblaster is pretty cautious. I don't have any intention of disassembling the gear set.

Posted on: 2011/6/23 8:39

|

|||

|

1937 120 1092 - Original survivor for driving and continued preservation. Project blog / Registry

1937 115 1082 - Total basket case, partial restoration, sold Hershey 2015 Project blog / Registry |

||||

|

||||

|

Re: Rear end seals

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I would NOT!

Posted on: 2011/6/23 12:58

|

|||

|

||||

|

Re: Rear end seals

|

||||

|---|---|---|---|---|

|

Home away from home

|

Recipe for disaster. Sandblast comes out at about 100 mph and some of it is microfine. Rags are porous. You made no mention of how far apart the rear would be, drums removed?? backing plates??

If above are not removed, they must be afterwards and evrything cleaned and flushed with solvents. Pinion, clean the area, seal with duct tape, then seal again. This stuff gets through almost anything. Remember, dict tape is much cheaper than rebuilding a rear end.

Posted on: 2011/6/23 13:01

|

|||

|

||||

|

Re: Rear end seals

|

||||

|---|---|---|---|---|

|

Home away from home

|

my 39 120 was leaking from the rear end - it had the original leather seal. Terry Weiss in Tyler TX replaced it with a modern bearing about 7 years ago. Still no leaks.

Posted on: 2011/6/23 15:36

|

|||

|

||||

|

Re: Rear end seals

|

||||

|---|---|---|---|---|

|

Home away from home

|

Remove the seals BEFORE ordering any seals. For some general seal applications there are seals available with an offset rubber lip. The offset rubber lip is designed to avoid any groove that may have worn into the shaft due to the old seal.

So it is advisable to disassemble, inspect for any groove worn in the shaft sealing area and then try to order seals accordingly. As a side note: the snadblasting warning has been well advised here. I won;t bother to emphasis those warnings any further.

Posted on: 2011/6/23 16:25

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: Rear end seals

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks to everyone for all the thoughts. I appreciate all the thoughts, concerns, and opinions. I am still planning on sandblasting the rear end however. It will be fully assembled, with doubled duct tape and cloth over the pinion. I will also seal the axle vent and the bolt hole for the brake line distribution manifold tightly and instruct the sandblaster to avoid getting too close to those areas.

I'm sandblasting the rear end because it has a heavy layer of surface rust and scale, and I don't see any other way of getting it all removed. I could spend a month with a wire wheel, and I don't think it would get all the rust off. The frame is restored, so I don't want to half-ass putting the rear end back together.

Posted on: 2011/6/26 8:13

|

|||

|

1937 120 1092 - Original survivor for driving and continued preservation. Project blog / Registry

1937 115 1082 - Total basket case, partial restoration, sold Hershey 2015 Project blog / Registry |

||||

|

||||

|

Re: Rear end seals

|

||||

|---|---|---|---|---|

|

Home away from home

|

Before you get your underpants in a bunch consider the following. There are no "general" seal applications, each and every application is specific as to make model ID,OD width, lip type etc. You cannot walk into an auto parts store and ask for a pinion seal, oh any general type more than you can order a "general " type engine piston.

I have disassembled hundreds of Packard rear ends and never saw a groove worn in an axle or pinion shaft, Packard knew its metallurgy and never skimped on quality of these items. Yes, I've heard there are offset seals and repair sleeves for grooves, but I believe they are for newer cars that have such a history. Relax, get your seals before you do the job and you'll have a great drip-free Packard

Posted on: 2011/6/26 20:01

|

|||

|

||||

|

Re: Rear end seals

|

||||

|---|---|---|---|---|

|

Home away from home

|

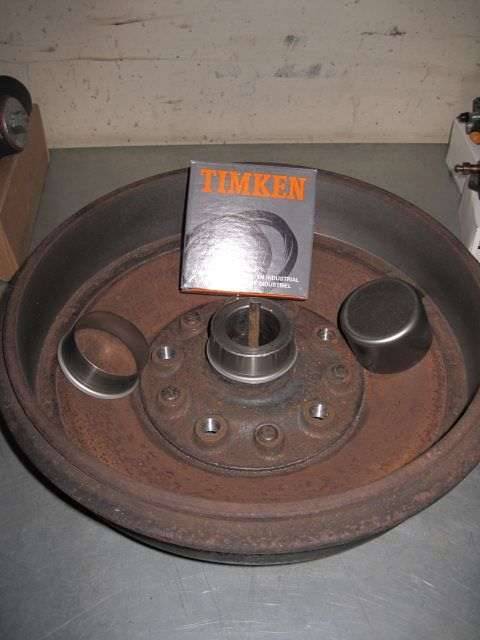

SpeediSleeve/RediSleeve have a broad range of repair sleeve sizes to fit many applications. You just have to get a good bearing and/or seal person who will take the time to go through the catalogs and find the right application. I used them on my '47 Clipper Custom to repair the area where grooves had been worn on the brake drum areas where the outer axle seals had rubbed.

Attach file:  (28.82 KB) (28.82 KB)  (33.33 KB) (33.33 KB)

Posted on: 2011/6/26 21:16

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: Rear end seals

|

||||

|---|---|---|---|---|

|

Home away from home

|

Seals are NOT necessarily excliusive to ANY Make model and year of vehicle. There mite be a few such seals that are but none that i have ran in to over 40+ years.

Some but not all OEM seals (installed AT THE FACTORY) may not have a number on them. IF the seal has a number on it then most likely it can be found at any parts store and fits a VARIETY of applications of different Make, model and year. ANy good parts store or mechanic worth his salt knows this. I have a large box full of about 150 seals here ranging from early 1950's up to present. Mostly originaly acquired for GM and AMC application that i know of. But they are direct and perfect fit and replacements across Ferguson, Jeep, Dodge, riding lawn mowers, 56 Packard Executive, John Deere, and the list goes on.

Posted on: 2011/6/26 21:34

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||