|

Re: 1930 7th series standard eight Motor Oil Pump Cleaning

|

||||

|---|---|---|---|---|

|

Home away from home

|

Go buy a gallon of E85 and let it soak in that for a week or so, it'll be all shiney and new when you're done. The alcohol will get rid of all the gunk that's hiding in there. I'd run it with a drill every couple of days or so to work it through, though.

Posted on: 2008/12/26 13:50

|

|||

|

||||

|

Re: 1930 7th series standard eight Motor Oil Pump Cleaning

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

A simple adjustable pin spanner, a rather standard tool, should remove the cap easily, though I've never gone this far with this vintage pump either. I know you want it clean inside, but despite the fact that lacquer thinner is a great solvent, I'd be a bit reluctant to use anything other than kerosene if you're going to power the gear rotation. I doubt new gears are obtainable for this pump and as you know the fit between the gears and housing is tight, and critical. I hate to think of all the grit swirling around the gears. Perhaps you remember the old caution about never cleaning roller and ball bearings in gasoline or strong solvent, but to use kerosene which has a (slight) lubricant quality to it (think of the gear pump in your home oil-burning furnace). I think I'd either try to get it fully apart, or rely more on soaking and rinsing than powering it with gritty solvent.

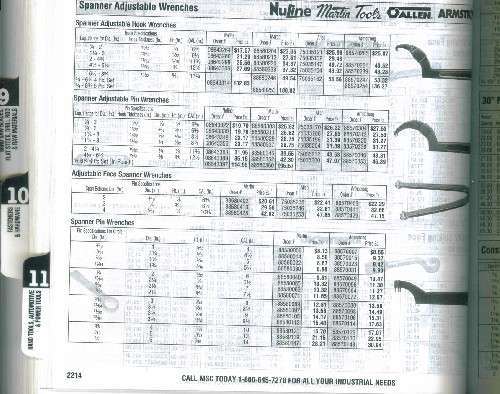

EDIT. Picture is worth how many words? Second from the bottom in this page from the MSC master catalog.

Posted on: 2008/12/26 13:57

|

|||

|

||||

|

Re: 1930 7th series standard eight Motor Oil Pump Cleaning

|

||||

|---|---|---|---|---|

|

Home away from home

|

Eric, Owen,

Thanks tons for the advice. I have kerosene here, so I will go with the soaking. I appreciate the warning. Hopefully the speed at which I spun (very slow), and the length of time (30 seconds) will not have resulted in any big damage. Also thanks for the catalog page. Very handy looking tool, but I guess not needed for now. Happy New Years folks! Tom

Posted on: 2008/12/26 14:46

|

|||

|

||||

|

Re: 1930 7th series standard eight Motor Oil Pump Cleaning

|

||||

|---|---|---|---|---|

|

Home away from home

|

Tom, seasons greetings. It seems you could make a "spanner" type tool easily enough with a length of strap steel drilled with two holes in which to insert cap screws. Fasten the cap screws to the strap with nuts and away you go. This would be a MBT (Made by Tom) original. Take care.

Posted on: 2008/12/26 16:18

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: 1930 7th series standard eight Motor Oil Pump Cleaning

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

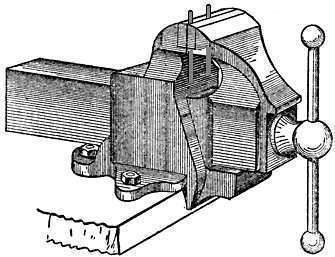

Hi Tom, Here is a technique that has been successful for me in getting these special spanner required pieces apart. Simply select 2 drill bits that fit your holes, mount them in your vise appropriately, and apply torque to the part.

You need the bits sticking up out of the vise as short as possible for obvious strength reasons. Attach file:  (17.73 KB) (17.73 KB)

Posted on: 2008/12/26 20:47

|

|||

|

||||

|

Re: 1930 7th series standard eight Motor Oil Pump Cleaning

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Now that's a tip. Have made many a custom spanner as JW suggests, but would never have thought of the other way around.

Posted on: 2008/12/26 20:51

|

|||

|

||||

|

Re: 1930 7th series standard eight Motor Oil Pump Cleaning

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

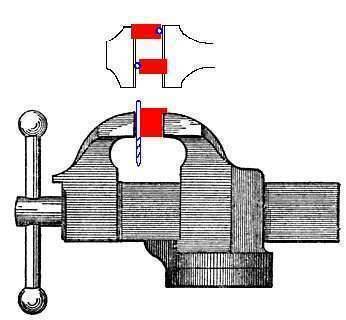

Just for a follow-up. If you need some space for shaft or protrusion, you can make up steel vise block as shown. the blocks can be 2 piece, no need to mill something out, but you do need a top lip on each block to keep it from dropping out as you adjust the distance. We all have a supply of dull drill bits that can be matched for size to use for these tasks. i hope this will help.

Oh yes, a groove cut in the clamping face of each block to keep the bit in place (with a Dremel or cutoff tool) is needed as well. Craig Attach file:  (15.15 KB) (15.15 KB)

Posted on: 2008/12/27 12:28

|

|||

|

||||

|

Re: 1930 7th series standard eight Motor Oil Pump Cleaning

|

||||

|---|---|---|---|---|

|

Home away from home

|

Craig,

Great Idea! Thanks tons

Posted on: 2008/12/27 14:35

|

|||

|

||||

|

Re: 1930 7th series standard eight Motor Oil Pump Cleaning

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

There is certainly a nice sense of accomplishment in making your own tools, as in the pins held in the vise and I admire that creativity. That said, don't neglect as you browse thru auto flea markets that there are usually a couple of guys selling tools. My face spanner has 6 sets of different size pins and was $1.00. I haven't used it often, mostly adjusting bearing races in differentials which often use this type of adjustment. But for a Buck it's pretty handy.

Posted on: 2008/12/27 19:19

|

|||

|

||||