|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Quite a regular

|

Howard/Kev;

I think we might be on to something. In the attached photo, the four way fighting on the left is what was on the engine and both sides are restricted to 5/64" (#47 bit) (filter side and feed to the lifter valley) and four way on the right is one I pulled from my stash and it too is restricted on both sides. Interesting, hmmm. I'm wondering if we should open the restriction to the valley feed based on your comments. Regards, Eric

Posted on: 2023/7/3 15:27

|

|||

|

||||

|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Home away from home

|

If this is a 359, it has the incorrect head too but you probably already know that.

Posted on: 2023/7/3 16:18

|

|||

|

All generalities are false.

Once I thought I was wrong but I was mistaken. Don Pierson Packard / IMPERIAL page CA DMV Licensed Vehicle VIN Verification 1951 Henney-Packard 3-Door Long Wheelbase Air Force Ambulance The 1951 Henney-Packard is For Sale! 1954 Packard Patrician 1954 Packard Patrician Parts Car 1956 Clipper Custom Sedan |

||||

|

||||

|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Home away from home

|

The 4-way fitting measurements you report below is is the same as what I have on my car, 1953 Cavalier - which is what came with it when I bought it. The lifters were quiet then.

Posted on: 2023/7/3 16:30

|

|||

|

||||

|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Quite a regular

|

As for the cylinder head, customer directed to use the 327 head from his 53 Caribbean which the 359 is going in

Posted on: 2023/7/3 16:35

|

|||

|

||||

|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

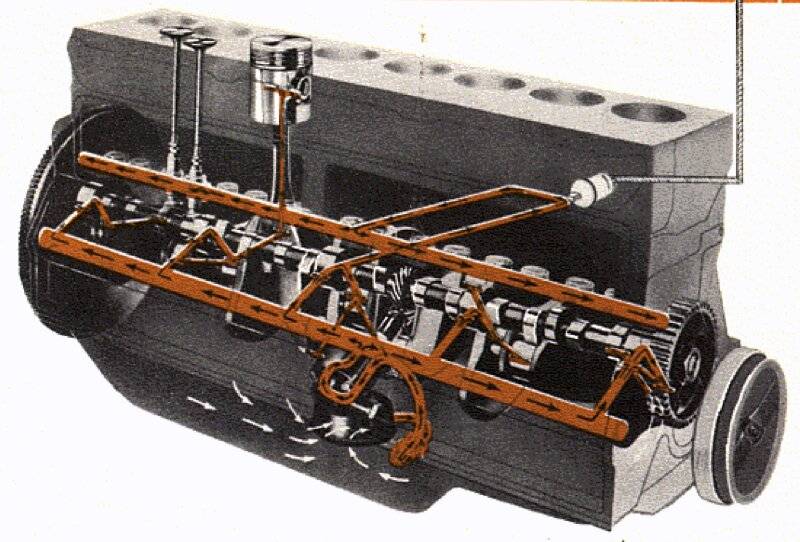

One relatively easy way you could test the possibility of too much oil thru the filter as the issue would be to temporarily disconnect the filter and install a 1/4" inverted flare plug in the filter side outlet of the 4 way fitting. All oil would then be forced into the lifter gallery circuit and if things quieten, look to not having enough filter restriction.

If still noisy then look to something with the lifters, stem clearance, or maybe something blocking full flow or possibly even a plug loose or missing allowing oil to escape too easily. On the head, only certain cast iron heads are interchanges for the aluminum 359. If someone remembers the specific heads Ross posted, please repost the info as I don't have it. Those that interchange can be used with hi octane fuel and tweaking the timing but others won't because it will be all but impossible to get rid of pinging. Just for grins, here is an illustration showing the oiling system. Their drawing only shows the 5 mains but 9 mains are the same except there will be the additional horizontal runs to each main bearing. For anyone interested, on an unknown engine count the number of exposed 1/8" plugs on the main gallery running along the length of the engine to quickly see whether it is a 5 or 9 main engine.

Posted on: 2023/7/3 17:33

|

|||

|

Howard

|

||||

|

||||

|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Home away from home

|

Here's the link to the head interchange chart. All the heads interchange but they produce varying compression ratios.

packardinfo.com/xoops/html/modules/newbb ... 5667&post_id=246062#forumpost246062

Posted on: 2023/7/3 17:43

|

|||

|

||||

|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

Right, and that is an excellent list. What I am referring to is a post Ross made a few years back where he mentioned a few specific heads and the markings on them that he has found will work with only minor tweaks. He also mentioned some he suggested staying away from because of the pinging issue.

Posted on: 2023/7/3 17:59

|

|||

|

Howard

|

||||

|

||||

|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Home away from home

|

After checking back in after an exciting day of making work for folks at work, I see the easy answer - wasn't. I'm inclined to agree with blocking off the filter and seeing what remains.

Intuitively, it seems more like a flow issue than a lifter issue, Waiting for what solves it.

Posted on: 2023/7/3 18:49

|

|||

|

If you're not having fun, maybe it's your own damned fault.

|

||||

|

||||

|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Quite a regular

|

It will be couple of days before I can provide an update as I was fighting starter engagement issues and found the teeth on the ring gear to be bad and pulled the flywheel to hopefully replace the ring gear.

I've been studying the oil flow diagram (colorized version) and I'm puzzled as to why they would restrict the oil flow in the 4-way fitting to the valley. I'm going to run a scope through the port and see if I can identify any possible restrictions before I experiment with opening up the restrictor on the opposite side of the oil filter restrictor. Thanks again for all the input

Posted on: 2023/7/4 10:16

|

|||

|

||||

710108329.jpg (338.14 KB)

710108329.jpg (338.14 KB)