|

Re: One oil pump modification now on file

|

||||

|---|---|---|---|---|

|

Home away from home

|

Interesting thoughts outside the box Rikki.

1. I've never seen an automotive oil pump with a ball or needle bearing. Those don't hold pressure. The major design flaw of the Packard V8 oiling system is the top of the pump body where the shaft exits is above the oil level of the pan. When the pump wears a bit, air can be sucked down the shaft and that's a bad, bad thing; that's why the lifters clatter. 2. The cast iron body itself is an excellent bearing material for the steel shaft. The problem with the OEM Packard V8 design is the bearing area isn't sufficiently long for the load it carries. Thus, it wears cone-shaped at the top. When I redesigned the Packard V8 pump, I doubled the length of the bearing area in the pump body. Then, I added a cast iron bottom plate with a cavity for an extended shaft on the bottom of the gear. That one isn't going anywhere. As proof of concept, I used one of my redesigned pumps in the Packard V8 I built for my '55 Studebaker truck. Oil pressure is just fine, as it will be on any engine with all clearances to spec. jack vines

Posted on: 2014/3/17 12:13

|

|||

|

||||

|

Re: One oil pump modification now on file

|

||||

|---|---|---|---|---|

|

Home away from home

|

i am sure this question is somewhere,,but why does the 56J oil pump use a gasket and Packard did not?, sucking air at main?

Posted on: 2014/4/26 22:21

|

|||

|

Riki

|

||||

|

||||

|

Re: One oil pump modification now on file

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

sucking air at main? That side of the pump is always under pressure. Don't see how it could be sucking any air. jack vines

Posted on: 2014/4/27 6:35

|

|||

|

||||

|

Re: One oil pump modification now on file

|

||||

|---|---|---|---|---|

|

Home away from home

|

lack

any ideas on the gasket?

Posted on: 2014/4/27 16:58

|

|||

|

Riki

|

||||

|

||||

|

Re: One oil pump modification now on file

|

||||

|---|---|---|---|---|

|

Home away from home

|

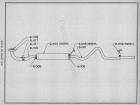

Per request, here is an easy modification I made to the oil pump in my Packup to prevent wear to its newly rebushed housing, and even it it does wear, to prevent any air from being drawn down the shaft. As discussed long ago here, this influx of air is what causes lifter collapse and bearing failure.

I crossdrilled the housing so that a small amount of oil from the output side is fed into the input shaft bushing. First photo shows the general trajectory of drilling. The vertical location is approx. in line with the centerline of the relief valve and the object is to hit the output passage just past the relief valve seat area. First step was to drill a hole from the outside only as far as the input shaft bore and make just a drill point mark on the far side of the bore. I used a 9/32 for this. Second step was to drill a very small hole, about 5/64 through into the oil output passage. Done If you like you can plug the entrance hole with a wee screw, but if your shaft fits nicely that will hardly be necessary. Last photo shows the drill bit through.

Posted on: 2014/7/1 6:35

|

|||

|

||||

|

Re: One oil pump modification now on file

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Some years back, member PackardV8 discovered an important feature in the SBC oil pump body that was lacking in the Packard unit - a cast channel that provided a bit of oil to lubrictae the driving shaft.

Yet, I was never quite sure how I would go about carving a similar channel in the Packard pump body without possibly creating more problems. Later, I decided it would be simpler and better to drill a small hole from the output passage of the pump to the driving shaft bore, but - again - I wasn't quite sure how to accomplish that (trajectory, diameters, etc.). Ross, I think your approach - requiring nothing more than a vise, an electric drill, and some bits - is exactly what's needed. It seems very much in the spirit of what the factory might have recommended as a field fix (if only they had more time).

Posted on: 2014/7/1 8:30

|

|||

|

||||

|

Re: One oil pump modification now on file

|

||||

|---|---|---|---|---|

|

Home away from home

|

Ross Quote:

As discussed long ago here, this influx of air is what causes lifter collapse and bearing failure. I beg to differ. Like many things Packard V-8, there are multiple causes of lifter collapse and bearing failure, not just influx of air. Also, there is poor pressure relief valve design which causes it to eventually stick "open" resulting in zero oil pressure. Then there is the fact that in a 60YO engine ALL the clearances open up after a while including that between the pump body and the gears making an already marginal oil pump into an inadequate one. With all due respect, I think you are just "putting lipstick on a pig," particularly when there is an excellent solution available involving new, proven parts (Olds pump & conversion). Craig

Posted on: 2014/7/1 9:07

|

|||

|

Nuke them from orbit, it's the only way to be sure! Ellen Ripley "Aliens"

Time flies like an arrow. Frui |

||||

|

||||

|

Re: One oil pump modification now on file

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks for posting this Ross.

Pictures, pictures, never enough pictures! Is the drilled hole through bushing, or underneath it?

Posted on: 2014/7/1 21:23

|

|||

|

||||

|

Re: One oil pump modification now on file

|

||||

|---|---|---|---|---|

|

Just popping in

|

I try to contact Jack vines no result?i have a problem to white my 400 from 1956.what to do?

Posted on: 2015/11/14 16:30

|

|||

|

||||

(77.54 KB)

(77.54 KB)