|

Re: Torsion Level System

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

That is odd. Maybe someone wanted more travel and removed the cushions or maybe the old ones gave up the ghost and a previous owner couldn't find a replacement. Anyway, without the cushion the A arm is dropping about as far as it can so don't think there is much more clearance to be had from that end unless something is disassembled. Possibly removing what is there would give another tiny bit but maybe not.

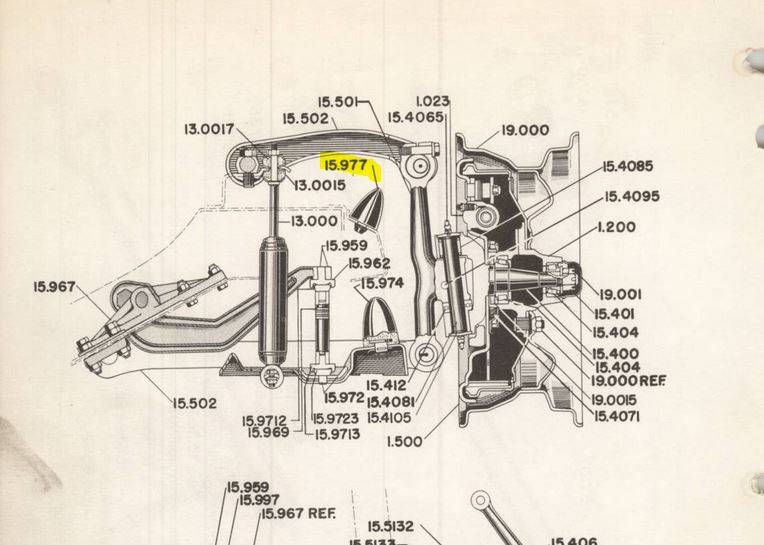

Troy made reproductions of the J-6065 tool but since he closed his shop I don't know if any of the other vendors picked up his inventory. Only ad I can remember seeing for the tool is from Dwight Heinmuller. If the load arm end is not as high as is shown in the service manual illustration with the tool in place and you can't raise it any more with the chain, maybe a tool would be a good investment.packardparts.org/products/parts/torsion-level-suspension/ Hopefully Ross will come along with another option and save the day.

Posted on: 2021/10/7 18:37

|

|||

|

Howard

|

||||

|

||||

|

Re: Torsion Level System

|

||||

|---|---|---|---|---|

|

Home away from home

|

Chevrolet uses the same.

As far as getting them in. Silicone grease .and lower the A arm. it will push in Jack up A arm to get it out. Or lower car..

Posted on: 2021/10/7 20:33

|

|||

|

Riki

|

||||

|

||||

|

Re: Torsion Level System

|

||||

|---|---|---|---|---|

|

Home away from home

|

I put the end pieces back in the #3 pin that I had removed and determined that a pin could only be another 3/8” to ½” longer and to be able to be inserted. Inspecting the Front Load Arm (FLA) shows that it points slightly down and not parallel with the ground (not sure what it should be).

I’ve examined the chain to ensure that nothing was hanging up with it and found there was plenty of clearance. I placed a piece of ½” threaded stock between the lower A arm and the FLA and using the nut on the threaded stock and tried to raise the FLA by turning the lower nut to no avail. I'm at a loss, but open to suggestions or thoughts.

Posted on: 2021/10/8 18:58

|

|||

|

||||

|

Re: Torsion Level System

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

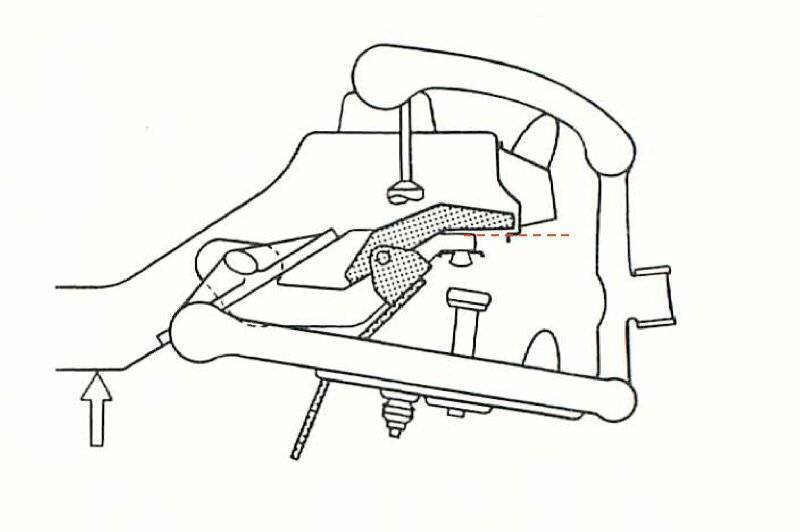

I can't tell where yours is from the photo but essentially with the tool, the top of the load arm is about even with the small ledge in the frame that the tool end rests on. It usually takes a bit of extra weight on the front to push down and lower the front end which raises the load arm to a position where the tool can be installed. After that the front end is jacked up so the A arms drop and rest on the top rebound bumper. That should give enough room to insert a pin even a bit longer than the 4 groove.

Posted on: 2021/10/8 19:19

|

|||

|

Howard

|

||||

|

||||

|

Re: Torsion Level System

|

||||

|---|---|---|---|---|

|

Home away from home

|

Problem solved. While the approach with a chain is a viable solution, my execution was poor. I noticed that while lowering the upper A arm the Front Load Arm (FLA) would also lower at a slower rate because of where the two steel bars were placed. Therefore, I changed anchor point to a place on the frame. To get things to work correctly I performed the following steps using ¼” Garde 70 chain, 3/8” grade 5 bolt & nut, spring compressor hook (SCH) , and a ½” x 6” carriage bolt with nut & washer.

1) Jacked up the car using the cross member until both front wheels were off the ground and rested the car on two jack stands. 2) Removed the wheel 3) Jacked the lower A Arm up until the car began to rising off the jack stands 4) Removed the shock absorber 5) Wrapped the ¼”chain around the FLA near it’s end and bolted it together with the 3/8’ bolt 6) Placed the SCH on the carriage bolt 7) Took the carriage bolt up through the shock absorber hole with the SCH under the frame side. Then screwed the nut/washer on the carriage bolt on engine side of the hole 8) Connected the SCH to the chain and the screwed the nut on the carriage removing all the slack in the chain. 9) Lowered the jack that was holding the A Arm up 10) At this point the existing pin falls out and there was plenty of room to install a #5 pin Right now I have a #4 pin in the car and the right side is a little over ½” lower. I’ve ordered the upper A Arm rebound bumpers for the car. When I get it, I’ll replace the #4 pin with a #5, install the rebound bumper, and new shock absorber. I want to thank everyone that provided input on the task

Posted on: 2021/10/10 19:27

|

|||

|

||||

Plate 31G.JPG (58.19 KB)

Plate 31G.JPG (58.19 KB)