|

Re: Ultramatic reactor end play measurement

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

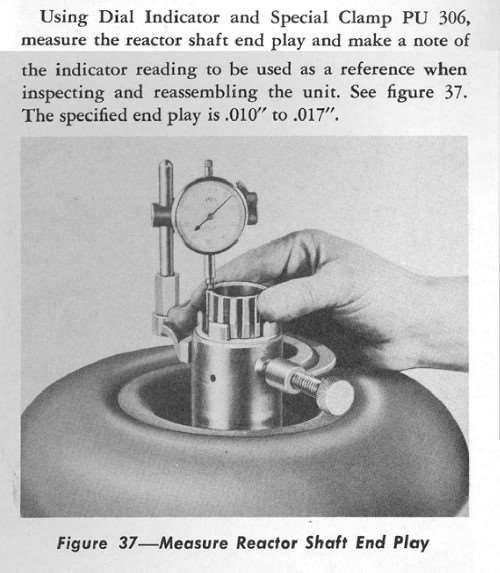

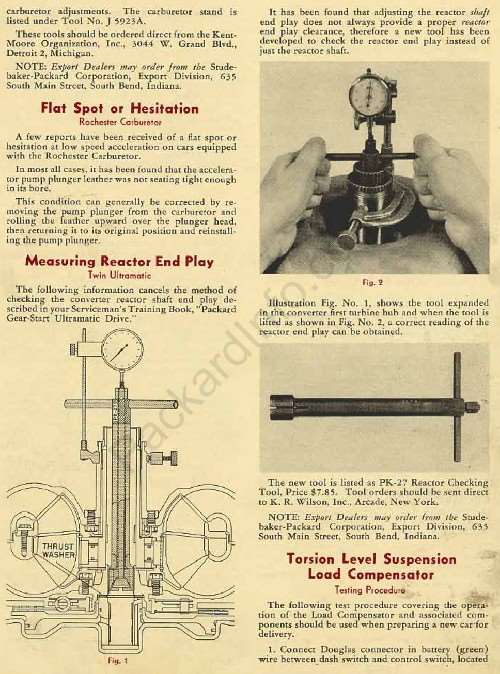

I don't know how inaccurate the original method of checking end play was but due to the reactor shaft being a separate piece, I guess with wear or if the sprags were loose there was potentially enough play between the two pieces that by lifting the shaft only the reactor might slip giving a wrong measurement. They came up with the PK 27 tool to lift the turbine, reactor and shaft as a unit.

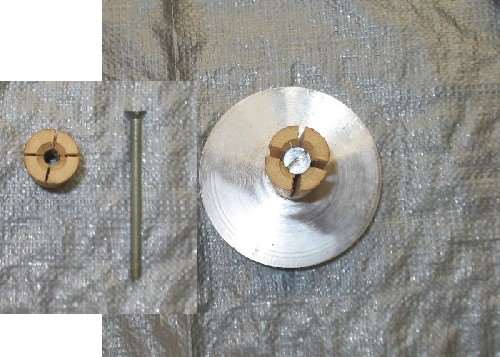

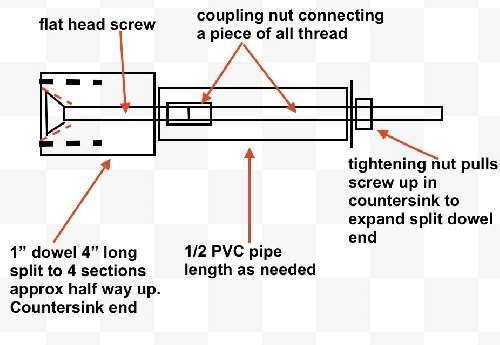

You could try the original measuring method on yours but if you want to go farther, I made a quickie and crude contraption out of scrap on hand to test the concept of making a home made tool. I didn't have a good enough scrap selection to make a proper tool but with what I had I believe everything needed could be bought at the hardware store for not much money. The method sort of duplicates the original and, with proper hardware looks like it might work for a limited use tool. The turbine spline space is about 1 1/16" diameter so I used a 1" hardwood dowel about 4" long. Nylon rod should work too. Drilled it thru the length and then did a counter sink on one end for a flat head 1/4-20 screw. Sawed upward from the end of dowel about 2" so end can spread outward in 4 sections. By tightening the nut, it pulls the screw head up against the countersink bevel and forces the sections outward to grab the splines on the turbine. The dowel ends move a bit and may want to split so wrapping a layer of tape on the unsawed section should prevent that. It only needs a layer or two of tape so tape doesn't bulk up and prevent the dowel from sliding into the turbine splines I would guess the entire tool needs to be about 8" long. Finding a single screw that long might not be easy so a coupling nut in the center to add a section of all thread or another screw would take care of needed length. Use a piece of 1/2" PVC pipe to complete the tool not forgetting to leave enough space to grab the screw end with vise grips to hold it while tightening the nut to pull up the head and expand the end. Some washers would spread the load at the end of the PVC pipe.

Posted on: 2017/8/2 11:48

|

|||

|

Howard

|

||||

|

||||

|

Re: Ultramatic reactor end play measurement

|

||||

|---|---|---|---|---|

|

Home away from home

|

Howard,

Thanks. I had been looking at using expanding rubber plugs, but they required a tight initial fit to be able to expand the plug. Attached is a picture of the tool made from your info. It needs to be tightened until it spins the turbine to keep it from moving when lifting. It provides consistent readings. Thanks again

Posted on: 2017/8/13 14:02

|

|||

|

||||

|

Re: Ultramatic reactor end play measurement

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Sometimes crude and simple pays off. Glad you were able to run with it and make it work.

Posted on: 2017/8/13 19:02

|

|||

|

Howard

|

||||

|

||||

(95.48 KB)

(95.48 KB)