|

Re: 56 Patrician bought off ebay

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Brian, thanks for the additional comments. A big thank you also for your work in documenting all the various codes that made my looking it up so easy. We all appreciate the effort that goes into that type of research.

Posted on: 2010/7/5 13:06

|

|||

|

||||

|

Re: 56 Patrician bought off ebay

|

||||

|---|---|---|---|---|

|

Webmaster

|

Quote:

This has now been fixed. Thanks!

Posted on: 2010/7/5 14:18

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: 56 Patrician bought off ebay

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Today, I got all the T-L links hooked up on the Pat and made a new gasket for the T-L control box. I plugged all the wires into their proper coded terminals. An observation that I have not seen documented, but became important is where each limit switch goes. The switch with the orange/pink wires is installed on the drivers side of the T-L gearbox.

I hooked up the battery and slid back underneath the car. I had not yet installed the turnbuckle link as I wanted to manually move the lever on the control assy (4.2253) to test everything. I swung the arm to one side and after 3-4 seconds the T-L came to life and rotated the auxiliary links. I swung the lever to the other extreme and waited - and waited. I heard the solenoid kick in but no movement from the motor-compensator. I let the lever return to the neutral position and waited about thirty seconds. I pushed it to the stop once more and after a few seconds I heard the solenoid engage but no movement. I crawled out from under the car and walked into the next bay for a cup of coffee and to ponder the problem. While explaining the problem to friend AL, I heard the motor kick in. Running back to the Pat bay, I disconnected the battery. I slid underneath the chassis dreading what I might see. No harm done. Now I had to figure out why the solenoid completed the circuit when the control lever was in the neutral position. My theory is that the solenoid moved internally when I moved the control lever, but didn't complete the circuit because of rust/oxidation on the plunger. It stuck there in the engaged position and later (while I was drinking coffee) it finally made internal contact and completed the circuit. I have no other logical explanation. Perhaps this is what happened to the original T-L?? In my mind, I had been blaming someone who manually grounded the solenoid which will damage the links and gears. It now seems likely that the old solenoid is the culprit. I am going to order two new Cole-Hersee solenoids #24046 as recommended by Mr. Pushbutton. If anyone else has a theory, I'd like to hear it.

Posted on: 2010/10/1 20:46

|

|||

|

||||

|

Re: 56 Patrician bought off ebay

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

A good theory. If the switch felt mechanically good and you heard the solenoid come in and no action, not much else left is there. Be interesting when you change them if you tore it apart and let us know.

Posted on: 2010/10/1 21:28

|

|||

|

||||

|

Re: 56 Patrician bought off ebay

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I always enjoy autopsies to determine why a component failed and will do so on this solenoid.

Posted on: 2010/10/1 21:32

|

|||

|

||||

|

Re: 56 Patrician bought off ebay

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The old solenoid had a lot of "mung" on the copper ring that engages the studs and routes current to the T-L motor. I can understand why it didn't make contact, but it doesn't seem like it would stick in the engaged position. I may have freed any internal corrosion just by slicing open the end of the solenoid.

The new solenoids are a little longer and almost touch when fitted up. The copper threaded studs are a bit shorter and a different thread. But everything did bolt up and the T-L system now works as designed. The next one of these I do, I will remove the lever assembly (15.933) so that I can easily torque (20 ft lbs) the end plugs in the links without fighting the tension of the auxiliary torsion bar. I would torque the end of the link attached to the lever and then attach the link to the lever assy - compensator (15.922). When done you can manually run the motor to align the lever assembly (15.933) with the aux T-L bar and align it to slip onto the end of the aux bar.

Posted on: 2010/10/10 0:18

|

|||

|

||||

|

Re: 56 Patrician bought off ebay

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Sent the water pump off to Arthur Gould to rebuild. He was able to save the bakelite impeller, which in my opinion, pushes more water than the normal metal impellers. Also called Daytona carburetor and ordered the kit for #7008610.

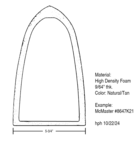

Removing the AC compressor is a real PITA because one nut is hidden up under the compressor support. Had to remove it to extract an old cruddy thermostat. Attached pic of NOS impeller. You can see the vanes sticking out beyond the hub.

Posted on: 2011/4/1 22:42

|

|||

|

||||

|

Re: 56 Patrician bought off ebay

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Is your compressor in good shape, I hope. You're right, mount is a PIA and location is not one of Packards better ideas.

Next time you are near the car, would you mind checking that measurement on the box. I ordered the silver and will see what it looks like. Found another place that has more options.

Posted on: 2011/4/1 22:52

|

|||

|

Howard

|

||||

|

||||

|

Re: 56 Patrician bought off ebay

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I apologize Howard - meant to measure that box today. I will tomorrow. Finally used a stubby ratchet wrench to remove the nut (no, not me!). Have to buy all new belts tomorrow. Does anyone still make the old style belts or all they all cogged now?

Posted on: 2011/4/1 23:18

|

|||

|

||||

(57.38 KB)

(57.38 KB)