|

Re: 51Packard's....51 Packard

|

||||

|---|---|---|---|---|

|

Home away from home

|

2-18-11

Well, looks like my power antenna project is a failure. I cleaned everything that I could in my media blaster (not the spindle or bottom of the electromagnet). Reattached the wires with the crimp connectors and heat shrink. That insulator plate had a rub mark on it so I assumed it was used to protect the wires from the turning spindle so that is where I installed it. The felt was coming off the bottom inside of the housing, so I glued it back on. The glue made the felt hard though. I "crushed" it with a wood dowel and hammer. Next I put some grease on the ball bearing and put it in the middle of the felt ring. I also put grease on the bearing and bottom post of the spindle. Also used grease to hold the spring in place. When I put the internals back in the housing, the electromagnet does not go all the way to the bottom to use the small screws (the ones I had to drill out). The spindle still turned freely. Put oil on the felt locations on the gear section of the motor. Then I added the gear section and screwed it together. Hooked it up to the battery charger and nothing happened. No hum or anything. I have no idea what went wrong (or what went right for that matter).

Posted on: 2011/2/18 19:42

|

|||

|

[url=h

|

||||

|

||||

|

Re: 51Packard's....51 Packard

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Don't give up yet. If you haven't discovered anything obvious, it would help to do a continuity check & make sure each field coil is good. It looks as if they sat in whatever got in there and do look a little sad. Also, there is a little copper strip on the bottom of that fiber board from one of the brush terminals to make contact with the case for ground. If no luck finding a problem there, then I would do a check in sequence to isolate the problem.

Place one meter lead on the terminal where one brush attaches to the two coil leads. With the meter on ohms, use the other probe to touch the metal support and make sure a coil isn't shorted. If good there, then connect to each of the harness wire leads in turn. Each should read a short there since there is no resistance to speak of in those coils. If those are both good, then put the armature in so it makes good contact with the brushes. With the meter still connected to the coil and brush terminal, check for a shorted armature winding by touching the probe to the steel in armature--both the shaft and the outer part. If good, then connect the other meter lead to the other brush and check continuity as the armature is rotated in the brushes. If that checks OK, then reassemble and put one lead on the case ground. Connect the other lead to harness wire(s) to make sure that little copper piece is making a good internal ground connection when assembled.

Posted on: 2011/2/18 20:28

|

|||

|

Howard

|

||||

|

||||

|

Re: 51Packard's....51 Packard

|

||||

|---|---|---|---|---|

|

Home away from home

|

I dont mean to be a kill joy here but I too have been down this road.the guts of my unit was worse than yours but be careful, it will not take long to fry the feild or the windings when you try it.Do your self a favor send it in to some one who knows this unit.Arizona Packards comes to mind.It will save you MUCH greif and maybe MUCH $$$ If you really want this unit to work, this is the way to go, no not cheep but cheeper in the long run if you dont send it in and it fails in almost a for sure fry job in the car underway later. BHW

Posted on: 2011/2/18 22:04

|

|||

|

||||

|

Re: 51Packard's....51 Packard

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks guys. I'll try HH56's tests first. I know how a motor works in theory, but I have no experience actually testing one to find out what is wrong.

Brians51, how much was it to rebuild your motor? I remember you posting something a while back asking how to get the antenna out of the car when it was still extended so I guess that is when you had trouble. From the price of the one on ebay, I would rather convert this one to a manual antenna. The one on ebay is almost as much as I paid for this whole car!

Posted on: 2011/2/18 23:57

|

|||

|

[url=h

|

||||

|

||||

|

Re: 51Packard's....51 Packard

|

||||

|---|---|---|---|---|

|

Webmaster

|

I fixed mine, and I am dumb as a post! So anything is possible with a little tinkering.

Posted on: 2011/2/19 0:14

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: 51Packard's....51 Packard

|

||||

|---|---|---|---|---|

|

Home away from home

|

While I respect and look up to Big Kev no one "as dumb as a post" can fix these unless they are not to bad off in the first place.Also that was not me with the stuck antenna.My saga goes on much longer than that.And is more involved than that. If you really want to know what it cost I will tell you but suffice it to say it was "Cast in Gold,Platinum plated and Diamond studded!More than my house payment ever was!That is why I cautioned you on it.It would not take long to fry it If you goofed.Mine was hopeless from the beginning.It just went down hill from there.While I agree anything is possible, yours doesn't look too good. B

Posted on: 2011/2/19 2:06

|

|||

|

||||

|

Re: 51Packard's....51 Packard

|

||||

|---|---|---|---|---|

|

Webmaster

|

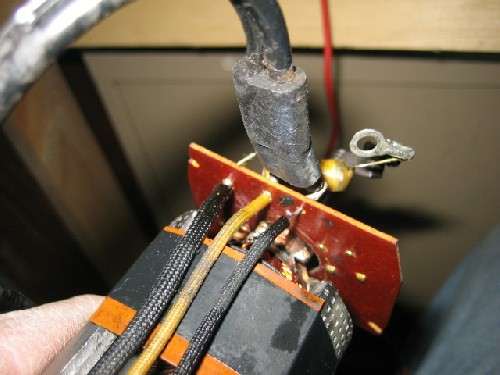

Some pics for reference:

Posted on: 2011/2/19 2:33

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: 51Packard's....51 Packard

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Kev, any idea what year yours is. The one I have is early--probably off a 51 and believe the one being worked on is too.

There appear to be several changes between the two. Maybe for a reason because of problems? There was a service article or two early on about sending non working antennas back to the factory for credit. Must have been a problem because there was another a bit later saying too many antennas returned were unrepairable because of damage. Had instructions on how to collapse or remove the mast from non working antennas so they could be shipped. Any coming back from then on with broken or bent masts would not get credit. The noise or arc supressor capacitor is probably minor but a bigger change is the brush screwing directly to ground on yours instead of being connected to a terminal. Mine has ground being made by a copper strip connected to a terminal under the fiber and squished or otherwise making contact with the case. It also has a contact between which appears to be a circuit breaker affair. If 51Packard's is the same, seeing both were eliminated on later antennas, either might be a good place to concentrate. Attach file:  (27.44 KB) (27.44 KB)

Posted on: 2011/2/19 10:16

|

|||

|

Howard

|

||||

|

||||

|

Re: 51Packard's....51 Packard

|

||||

|---|---|---|---|---|

|

Home away from home

|

I think my antenna is original to the car, but can't be sure. The antenna mount was just as nasty as the motor so I think it is original. It seems to be somewhere between HH56's and BigKev's. One of my brushes screws directly to the base, but I do not have the suppressor. I also do not have the silver strip shown on HH56's. I'm not seeing any copper strip on the fiberboard of mine. The wires on both of yours look a lot cleaner than mine. When I was taking it apart, I know there was some magnetism to it because metal was sticking to it.

I'm not too good on the terms HH56 was using in the descriptions of the tests I should make, so I will probably take pictures while I do them to make sure I am understanding what he is saying and doing it right.

Posted on: 2011/2/19 11:18

|

|||

|

[url=h

|

||||

|

||||