|

Re: Jeff's 48 Custom 8 Victoria Project

|

||||

|---|---|---|---|---|

|

Home away from home

|

Great job, Jeff. Terrific pix. Beautiful model.

Posted on: 2013/7/1 23:07

|

|||

|

||||

|

Re: Jeff's 48 Custom 8 Victoria Project

|

||||

|---|---|---|---|---|

|

Home away from home

|

The Packard would wait a over a month as I worked on more daily drivers, took care of some tasks that needed my attention, and made my yearly pilgrimage to Chryslers at Carlisle.

Now it was time to get the engine compartment cleaned up and painted. Nothing groundbreaking here, lots of scraping, a thorough power washing, and some paint. It's amazing how rock-hard 60 year old dried up grease that's mixed with sand can get. It was almost like trying to scrape off cured concrete. I removed what I could by hand, and the hot water pressure washer was able to melt off the remains. I used Eastwood's single stage urethane for the color coat. Even though the paint sprayed and covered well, I wouldn't recommend the black for an exterior paint job on a car. It's not a pure black and has the same grayish-brown hue under direct sunlight that you get with black Rustoleum or Krylon spray cans. It would be ok to use their colors for a budget-minded paint job, but just not the black. Also, don't trust the paint chip chart that they supply. For a different project, I ordered what I thought would be a medium metallic red and ended up with a metallic pink car. July to September 2012. Engine bay cleanup and painting Attach file:  (76.09 KB) (76.09 KB)  (95.81 KB) (95.81 KB)  (137.89 KB) (137.89 KB)  (150.69 KB) (150.69 KB)  (182.64 KB) (182.64 KB)  (119.06 KB) (119.06 KB)  (79.82 KB) (79.82 KB)  (79.20 KB) (79.20 KB)  (89.04 KB) (89.04 KB)  (87.36 KB) (87.36 KB)  (65.04 KB) (65.04 KB)  (66.52 KB) (66.52 KB)  (77.18 KB) (77.18 KB)  (87.95 KB) (87.95 KB)

Posted on: 2013/7/1 23:37

|

|||

|

||||

|

Re: Jeff's 48 Custom 8 Victoria Project

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks Kevin and Joe.

Sadly, all the hardware had to be mixed together when it was cleaned and de-rusted, but the pictures I have of the cart will make great references to figure out what goes where. The originals are 3 megapixles, so they blow up huge for lots of detail. I didn't like the looks of some of the hardware, so I decided to replace it with new stuff. Many of the bolts had a porous appearance, with lots of tiny holes in the heads. I will save all the original pieces in case someone wants to do a concourse resto in the future. There's what appears to be an identical '48 Custom Eight convertible in the Registry that's fully restored, and it's a real looker. Jeff

Posted on: 2013/7/2 0:00

|

|||

|

||||

|

Re: Jeff's 48 Custom 8 Victoria Project

|

||||

|---|---|---|---|---|

|

Home away from home

|

This chapter is long on words and light on Packard progress, but it fills in a big gap in the timeline and some may find the shop upgrades helpful.

With the engine bay all painted it was time to prepare to work on all the bits and pieces that I had removed from the Packard. Considering that almost every part that came off of the car was rusted or corroded, media blasting equipment would be a must. I had one blast cabinet that I built back in the early 1980's when I was still a kid. It was poorly designed, so it would need to be upgraded or replaced. My shop air supply wasn't up to the task of providing the dry air needed for blasting either. All I had was a hose connected directly to the compressor. After much consideration, I planned out a system consisting of 70 feet of ?" steel pipe that will cool down the air before it arrives at the water separator. The separator is about twenty feet from the compressor, but the air travels through 60 feet of pipe on the way. The extra ten foot section goes to the hose reel that I use for my air tools. I installed a ball valve drain on the bottom of each pipe section, along with a regulator/separator and a Motor Guard filter. The system works excellent, especially considering how much water and oil my cheesy compressor pumps through the lines. Next on the to-do list, I decided to improve my old blast cabinet instead of spending $1000 on a new one. I had originally built it with a vertical front panel, not taking into account the shape of the human body. When you put your arms into the glove holes, your face was smashed against the viewing window. There's a good reason that all blast cabinets have the front panel angled back, away from your head. To use it for any length of time, I had to put wood blocks under the front to tilt the entire cabinet back. I stripped off the top section of the cabinet and made all new pieces. I bought all new accessories from TP Tools, such as gloves, glove holders, window and frame, pickup tube and gun, along with a media reclaimer. I decided to purchase a second blast cabinet for glass bead. I have a more aggressive media my original cabinet, which does a much better job cutting through rust than the glass bead does. Unfortunately, the new cabinet turned out to be one of the biggest pieces of junk that I've ever bought. It's a blow molded plastic cabinet made by ALC. Take my advice and never even consider buying one of these. I thought that it would be a quality piece since it was made in the USA, but it's really poorly designed. The sad part is that it wasn't cheap either. I found out later that I could have had a nice TP Tools metal cabinet that was on sale for only $50 more. One week into November, news came that the Packard engine was finally ready to be picked up. The final list of repairs included cleaning and sonic checking the engine block and cylinder head, resurfacing of the block deck and head, replacement of the exhaust guides and one valve seat, a complete valve job, setting the valve stem heights, replacement of the cam bearings, cylinder bores were ball-honed, along with magnafluxing and polishing the crankshaft. When I got the engine back to the shop I used a heavy duty wire wheel in an angle grinder to clean the rust off of the exterior of the block and head. A few weeks earlier I had spent way too many hours trying to find a suitable engine stand to hold the long and heavy Packard straight eight. I had found a real nice stand on a manufacturer's website, but it turned out to be discontinued, and I couldn't find anyone who still had one in stock. I settled on a Torin 1500 lb capacity stand that Northern Equipment sells. So far it seems to be handling the engine well, though it became tough to steer the stand once the engine was fully assembled. These modern engine stands aren't designed to bolt to the older engines with small bellhousing bolt circles, so I had to rig it up a bit. Later on I found that I had to space the engine out another inch to make room for the crankshaft flange. The 1985 Mustang GT that can be seen sitting outside the shop was going to push the Packard aside for the entire winter and into spring. The Mustang had been here for a year and a half and the owner was starting to miss it. It was here for an engine rebuild, an engine bay detail and preparation for a color change, along with an upgrade from a 7.5 to 8.8 rear axle. I'm really pleased with how it came out, so I had to throw in a few before and after pics. The Packard should look as good when it's done. The only other Packard-related progress for this time period was the rebuilding of the starter and generator by a local electrical shop. I've known the guys who run the shop since high school and they only charged me $160 to do both items. A real bargain. October 2012 to May 2013. Shop is upgraded. Mustang gets my attention while Packard waits it's turn. Attach file:  (33.86 KB) (33.86 KB)  (75.51 KB) (75.51 KB)  (60.91 KB) (60.91 KB)  (71.97 KB) (71.97 KB)  (79.03 KB) (79.03 KB)  (148.64 KB) (148.64 KB)  (79.50 KB) (79.50 KB)  (86.98 KB) (86.98 KB)  (84.57 KB) (84.57 KB)  (116.66 KB) (116.66 KB)  (100.37 KB) (100.37 KB)  (92.25 KB) (92.25 KB)  (65.20 KB) (65.20 KB)

Posted on: 2013/7/5 0:51

|

|||

|

||||

|

Re: Jeff's 48 Custom 8 Victoria Project

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Very nice on the engine stand. Beats the heck out of the typical HF offering.

Should you need to modify your mount any, Packard did some tests on various stands just after the war. Their mechanics chose one which mounted the long engines from the side. Attach file:  (20.01 KB) (20.01 KB)

Posted on: 2013/7/5 8:34

|

|||

|

Howard

|

||||

|

||||

|

Re: Jeff's 48 Custom 8 Victoria Project

|

||||

|---|---|---|---|---|

|

Home away from home

|

That's a neat looking engine stand. I bet that sucker is heavy, as it appears to be all cast iron. That's the way most of the currently available heavy truck engine stands are set up. They attach to the side of the engine to spread the load evenly. That vintage stand would make a nice display piece in an automotive memorabilia collection. There's probably a few of them still around.

Jeff

Posted on: 2013/7/6 1:24

|

|||

|

||||

|

Re: Jeff's 48 Custom 8 Victoria Project

|

||||

|---|---|---|---|---|

|

Home away from home

|

Sorry to keep everyone waiting for the next chapter in my Packard project blog. I started school in mid-July to get a commercial driver's license, and I haven't had much free time for non-essential endeavors lately.

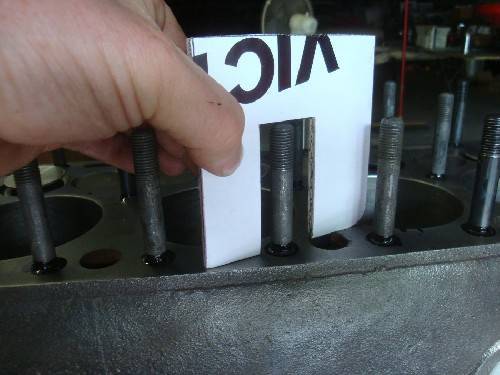

For this chapter, now that the long wait for lifter bodies and machine work is over, it's finally time to put the engine together. Assembling the Packard straight eight should have been pretty straightforward, but I didn't get very far before discovering a problem. First up was a fresh set of main bearings and a new rear main seal. I never put in a new rope seal before, but it turned out to be very easy after reading the instructions that came with the seal. The crank came next and I plastigauged the mains. The clearances on the bearings that I got from Kanter were inconsistent . The crank mic'd out at .001" below standard on all the journals, and I ended up with a touch over .0005" clearance on a couple of the mains. If the crank journals had been dead on standard, there would have been definite clearance problems with those bearings. Some bearings were right on the money at .001" and others were a bit over .0015". The bearings were of unknown origin and were supposed to be standard size. It was a close call, but all came out ok. Next came installing the pistons with new rings. That's when I discovered two cracked pistons. At first I thought that I would have to take a chance by installing the pistons and hope for the best, considering that it's unlikely that the engine will see more than 5000 miles in it's lifetime. I was surprised to find that Kanter had new standard-sized pistons, available individually. About three days later I had my new pistons ready to go in, only to find that they required different width rings and the piston pins were a slightly smaller diameter than the originals. I had to order new rod bushings from Kanter and my machine shop was able to order individual rings directly from Hastings so that I didn't have to pay for an entire new set. The machine shop installed the new bushings in the rods and sized them for the pins. The whole process took about two weeks from when I discovered the cracked pistons. With my last two pistons in, my rotating assembly was finally done. I had purchased .001" under rod bearings from Kanter. They were Clevite 77's, and the clearances were right on the money on all eight. New lifter plungers, valve keepers and springs were installed. I had previously inspected the oil pump and it was still in good shape. This was surprising, since the pickup screen was over 50% blocked solid. My tip of the day is to always remove the baffle from the screen to make sure that it isn't all caked up with crud. It's not obvious at all until the baffle is off. The oil pump was installed, along with the coolant distribution tube, the plate on the front of the engine, a new timing chain and gears. I decided to try something different on this engine to prevent it form leaking fluids. Over the years I've seen many nicely detailed vintage engines that are leaking oil and coolant, and I didn't want that to happen with this one. I fixed the paper and cork gaskets in place with 3M yellow weatherstrip adhesive, then ran a bead of Permatex Ultra-Black silicone on the inside of every gasket. My hope is that if the fluids never come in contact with the paper or cork, they should never leak. Time will tell on this one. Next up was the tedious task of installing all the head studs. I had purchased nine new studs from Kanter and found that the interference fit was too tight and needed to chase the threads so that they would go into the holes properly. I put sealer on all the threads for safe measure. The head gasket got a good coat of copper gasket sealer. That stuff is brutally sticky. I suggest hanging the gasket from a wire and spraying both sides. I sprayed one side, let it set up, then turned it over onto wax paper to do the other side. I barely got the wax paper back off of the gasket. I saved a little bit of money by buying new nuts and washers from Fastenall. The washers are a bit thicker than original, but acceptable for a driver. Lately I've been priming my engines with self etching primer before applying the color. Engine paint adheres well to cast iron, but tends to peel off of hardware and some smooth steel parts. Again, time will tell if it was a good or bad idea. The topcoat is Bill Hirsch paint from a rattle can. I'm pretty sure that the engine should probably be gray, but the owner wanted green, and I like the green much better too. There wasn't one single spec of paint left on the engine to tell what color it was when it left the factory. The Bill Hirsch paint lays on real nice. It'll be painful when the time comes to re-torque the head nuts. I have a special plastic-lined ?" inch socket for tightening chrome lug nuts, and I'm hoping it will minimize any damage to the paint on the nuts. May to June 2013. It's finally time to put the engine back together. Attach file:  (77.06 KB) (77.06 KB)  (79.73 KB) (79.73 KB)  (69.64 KB) (69.64 KB)  (83.04 KB) (83.04 KB)  (65.71 KB) (65.71 KB)  (61.77 KB) (61.77 KB)  (76.28 KB) (76.28 KB)  (87.84 KB) (87.84 KB)  (76.20 KB) (76.20 KB)  (73.11 KB) (73.11 KB)  (93.65 KB) (93.65 KB)  (96.48 KB) (96.48 KB)  (77.54 KB) (77.54 KB)  (73.89 KB) (73.89 KB)  (76.83 KB) (76.83 KB)  (85.76 KB) (85.76 KB)  (78.31 KB) (78.31 KB)  (90.95 KB) (90.95 KB)  (67.43 KB) (67.43 KB)  (81.98 KB) (81.98 KB)  (81.58 KB) (81.58 KB)

Posted on: 2013/8/9 1:17

|

|||

|

||||

|

Re: Jeff's 48 Custom 8 Victoria Project

|

||||

|---|---|---|---|---|

|

Home away from home

|

hi jeff; looks like you have a good start with your 2259, i got done with mine several years ago, it's in the registry. if you need any help let me know. mine is black with a black top. dell

Posted on: 2013/8/11 16:29

|

|||

|

35-1200 touring sedan 42-110 convertible coupe 48-2293 station sedan |

||||

|

||||

|

Re: Jeff's 48 Custom 8 Victoria Project

|

||||

|---|---|---|---|---|

|

Home away from home

|

Hi Dell, I did see your beautiful car in the registry. I was planning to contact you to ask if you had any more pictures of it posted somewhere on the net. If not, could you e-mail me some? I thought it would be good inspiration for the owner of the one that I'm working on. I was also curious if you had the same interior. It looks like you have red leather too, but do you also have the plaid cloth on your doors? If you do, the cars could have been twins, though I think this one may have originally had a light colored top on it.

Thanks, Jeff

Posted on: 2013/8/11 21:55

|

|||

|

||||