|

Re: R9 vs R11 Governor question

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Thru 50 the R9 and R11 governors are almost identical in appearance. Drive pinions may have differed between OD units but the inner guts were the same. Thru 50 where the Electromatic Clutch was still an option there are two wire pigtails on the governor. 51 and later units only have a single wire. If the action seems reversed I wonder if the wrong pigtail is connected to the OD.

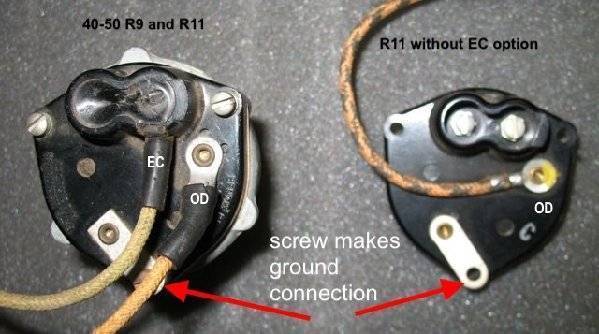

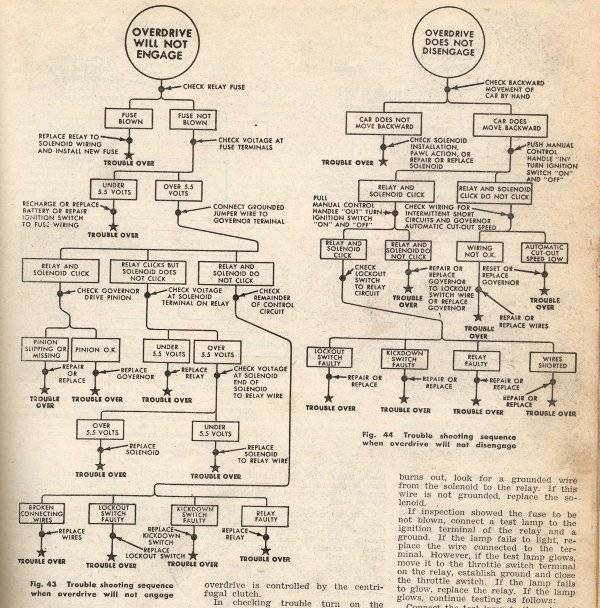

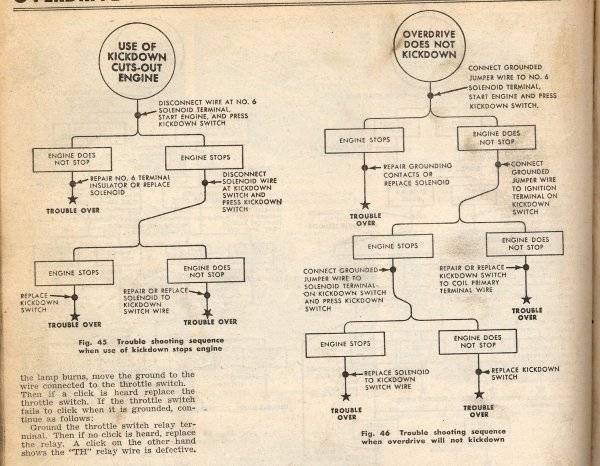

The OD wire comes off a bare riveted terminal exposed on the bakelite back. That wire is open and has no continuity to the case ground when the governor is below cut in speed. The wire for the EC comes out of a sort of a raised enclosure usually filled with tar and will show continuity to ground when the governor is still. When the governor reaches speed, the two wires change state with the OD wire going grounded and the EC wire now open. Ground supply for the contacts comes via a small metal jumper bar which connects via one of the screws holding the case bottom. The screw makes contact between the jumper bar and governor body which in turn is grounded by being screwed into the grounded OD body. If the connecting screw is loose or dirty that could cause some intermittent issues. The contacts are somewhat delicate and operate much like a microswitch. A very small movement by the governor flyweights moving the actuating collar is all it takes. Adjusted at the factory with special calibration equipt, there is an adjust screw under the tar. If someone has tried to adjust the cut in speed and moved the screw too much they could have damaged the contacts beyond repair. Here is a photo of the governor back and an R9 flow chart out of an old aftermarket manual that might help diagnose. Also, there is the Econodrive training manual in the literature section that has a lot of troubleshooting info.

Posted on: 2019/1/21 17:14

|

|||

|

Howard

|

||||

|

||||

|

Re: R9 vs R11 Governor question

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Howard Rules!

Posted on: 2019/1/21 19:24

|

|||

|

||||

(43.56 KB)

(43.56 KB)