|

Re: How to pull engine and transmission

|

||||

|---|---|---|---|---|

|

Webmaster

|

H264097 would be a 1949 (23rd Series) 288, 135 HP, Solid Lifters

If the serial was H291001 or higher then in would be 1950 (23rd Series). But either way, the exact same engine.

Posted on: 2009/7/1 16:20

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: How to pull engine and transmission

|

||||

|---|---|---|---|---|

|

Home away from home

|

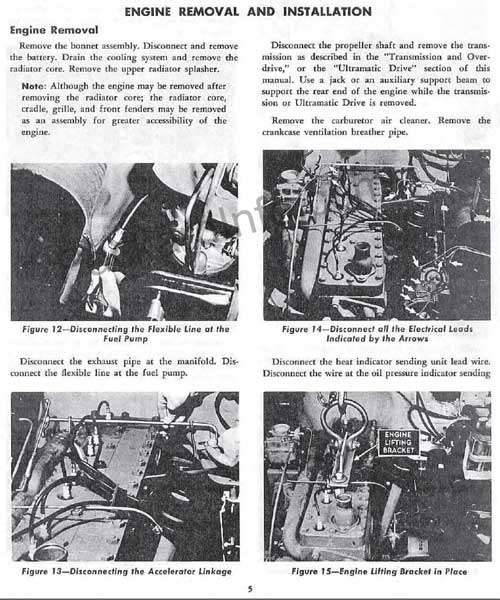

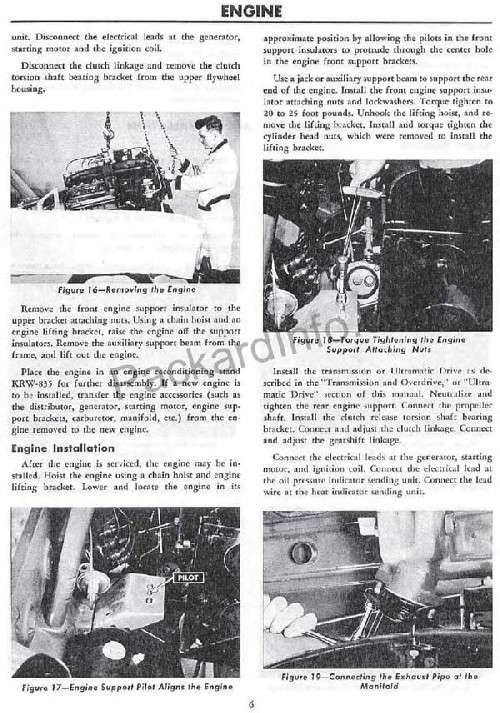

So, the original question was how to remove the engine, and whether to remove both engine and tranny at once or separate. I found in the 51-54 service manual you are to remove the tranny first and then the engine.

1946 - 1950 Service Manual 1951-1954 Service Manual

Posted on: 2009/7/1 19:33

|

|||

|

-Carl | [url=https://packardinfo.

|

||||

|

||||

|

Re: How to pull engine and transmission

|

||||

|---|---|---|---|---|

|

Home away from home

|

I have a spare engine that on Friday was pulled from a 1950 Packard that was being cut up for scrap. This spare engine is numbered H276066. Can you identify this one for me?

Posted on: 2009/7/5 12:27

|

|||

|

||||

|

Re: How to pull engine and transmission

|

||||

|---|---|---|---|---|

|

Home away from home

|

1949 288 5 bearing solid lifters, same as your other one. Not sure why the plugs are different, could be someone somewhere somehow in 59 years replaced the head or threaded for different size plugs.

You can check for yourself here: https://www.packardinfo.com/xoops/html/downloads/PackardEngineSerials.pdf

Posted on: 2009/7/5 12:54

|

|||

|

-Carl | [url=https://packardinfo.

|

||||

|

||||

|

Re: How to pull engine and transmission

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

IIRC, at some point during the 23rd (1950) series, the spark plugs were changed back to 14mm. Also lots of mechanics made their beer money drilling and retapping from 10mm to 14mm, usually after a stripped plug hole was encountered. Incidently, during 1951 Packard made a run of cylinder heads for the 356 engine with 14mm plug threads, these can easily be identified by the 1951 casting dates on 356 heads.

Posted on: 2009/7/5 14:15

|

|||

|

||||

|

Re: How to pull engine and transmission

|

||||

|---|---|---|---|---|

|

Home away from home

|

Dave, the information on the 14mm 356 heads is interesting. I was under the impression that the reason Packard used the 10mm spark plugs was to give them more flexibility in locating the spark plugs. Of course, now days there is more heat range selection with the 14mm spark plugs.

Posted on: 2009/7/5 16:24

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: How to pull engine and transmission

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I believe GM was the driving force behind the 10 mm plugs in the mid-30s. Their (Buick's) claim was they were better suited to the emerging higher compression ratios. Hard to think that at that point people thought 6.75 was high compression.

Posted on: 2009/7/5 17:47

|

|||

|

||||

|

Re: How to pull engine and transmission

|

||||

|---|---|---|---|---|

|

Home away from home

|

When I got the Packard I replaced the 10mm plugs trying to make it run better. When I recently pulled the head some of the plugs were almost finger loose! The tiny 12 ft-lb of torque is not enough to keep a preload on the plug. I noticed the short threads also, just wanting to be stripped. A 14mm plug would be more rugged and reliable and that is why I plan to swap to the slightly newer head with the bigger plugs.

By the way I managed to pull the oil pan and checked the bore condition before I pull the engine. The bore is standard 3.500" with a taper of .004 to .014 depending on the cylinder. Most are .010 taper. According the the Packard book this is marginally OK to just replace the rings (for minimal driving this may be a good choice right now). Does anyone have experience putting rings in an engine with this much bore taper? How long do you think it might last?

Posted on: 2009/7/7 14:15

|

|||

|

||||

|

Re: How to pull engine and transmission

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Some years back I re-ringed a 356 with about 0.007 taper; just cut the ridge, honed, and used standard rings. Thereafter it made no visible smoke, and still doesn't some 25 years later, though I don't know the accumulated mileage, probably less than 20,000. Sorry, no experience with taper of up to 0.014", but other than your labor and the cost of rings and a head and pan gasket, what do have to loose?. Since you're doing a "band aid" job you might also consider knurling the pistons or installing piston skirt expanders; though not something particularly admired by many, these things do have their place in the type of job you're contemplating.

Posted on: 2009/7/7 15:14

|

|||

|

||||

(63.28 KB)

(63.28 KB)