|

Re: Beating a Dead horse - 6v AC

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

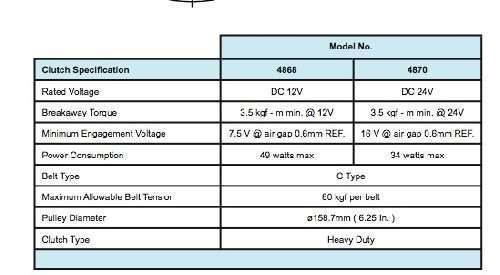

You've nailed the options since nothing 6v is available with a clutch unless you can find an old one--and then any parts to repair if needed probably won't be easily found. A few guys on other make forums have tried the decreased gap and apparently with mixed success. The Sanden FLX series (chart below) says minimum 7.5v needed so MIGHT possibly work on 6 if you can reduce that gap even further. Not sure how much current draw at 6v though or if heat due to wrong voltage and slippage or improper engagement would be an issue. If you are going to go clutchless as Packard did thru 54 then might be able to find a pulley for the shaft of the GM A6 or Sanden and replace the clutch entirely---HOWEVER--.

Temp control to keep evaporator from freezing will be the prime issue with the always on route. Secondary issue will be the increased load of compressor always moving refrigerant when trying to start engine. Postwar Packard (& others of that era) used hot gas bypass either via electrically adjusted thermostat & solenoid valve thru 54 and then a clutch for off but a self contained fixed temp modulating valve set above freezing for temp in 55-6. Those methods regulated temp and also enabled compressor to short circuit the freon to reduce load. To do that today would require some engineering, parts, and worse, is a hard system to diagnose issues should they arise. In the 50s, 60s & up thru gas crisis GM type reheat systems most used, the suction throttling and then later POA & other assorted named methods of restricting refrigerant flow to starve the evaporator might be adaptable for the freezing but still had clutches for the load. Even parts for those alphabet named systems are getting thin to the point some AC places now offer dummy valves to maintain the plumbing connections as replacements when those need work & suggest converting to cycling clutch like modern cars use. Guess what I've taken the long way to say is I don't see anyway around a clutch today. The 6v motor turning a compressor I don't know if it has ever been tried but as you mentioned, it would take a pretty good sized motor and pretty heavy current. There have been some who add a 12v battery and use another alternator to keep that charged for the AC and other 12v options while keeping the rest of car 6v.

Posted on: 2010/1/10 14:46

|

|||

|

||||

|

Re: Beating a Dead horse - 6v AC

|

||||

|---|---|---|---|---|

|

Home away from home

|

All very good information. I've been mulling this over in my head while out and about. If i have to put a compressor under the hood, i'd prefer a somewhat common one and a rotary as opposed to piston type and one that doesn't look too new (hence spending the bucks on an alternator that looks like a generator, to preserve the general time period "look". With that in mind, i think the compressor of choice is probably the GM A6 that was used in the 60's. Still lots of parts around, about 175 rebuilt without core, and looks kind of old, especially with receiver/dryer strapped to the side and painted factory black.

With that in mind, i'm going to yank mine of the shelf and take it apart to study it to see how the air gap adjustment works. I'm going to pickup a 2000lb engine stand and get the 327 mounted and hold it up to see what kind of mounts i could work with before getting it in the car. Then i'll make a decision. At the same time, i have a bigger around but way shorter GM one that i will research doing direct drive with. If i cold gut an old coke cooler or something else period correct looking, sand blast and paint it up all nice, and put it all in there, THAT'D be awesome. Maybe a deep cycle battery in there with it and some sound insulation, with nice big gauge wire running to it from the healthy charging system up front. So next steps i guess are play with the compressor i have and a 6V power source with ok amps and a power drill to see what kind of lock up i can get for option A and research decent 6v motors and compressor RPMS for option B and leave the always on option for last if need be.

Posted on: 2010/1/10 15:45

|

|||

|

||||

|

Re: Beating a Dead horse - 6v AC

|

||||

|---|---|---|---|---|

|

Home away from home

|

According to this link from hemmings:

hemmings.com/hmn/stories/2006/10/01/hmn_feature32.html The GM A6 was available in a 6V clutch version. I'll read up on that as well. From what i've read just lightly, you need about 1700-2000 rpm for this kind of compressor to work. We'll see what we can find in 6V motors along those lines.

Posted on: 2010/1/10 16:13

|

|||

|

||||

|

Re: Beating a Dead horse - 6v AC

|

||||

|---|---|---|---|---|

|

Home away from home

|

Posted on: 2010/1/10 16:28

|

|||

|

||||

|

Re: Beating a Dead horse - 6v AC

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Didn't see the reference to 6v version in the article so be interested in what you find out. I hadn't heard any of those available since came out late 50's. Not impossible as they mentioned uses in industrial applications-but believe all the cars listed were 12v. I have a 54 GM rotary style predecessor with clutch. Not sure what it's designation is but looks like the Packard version in manual which was without clutch. The clutch is a solenoid mounted atop the frame with a lever that goes over front of pulley & is hinged at bottom. When energized, solenoid pulls lever which pushes on a small "button" in center of pulley and engages the mechanicals.

Posted on: 2010/1/10 16:30

|

|||

|

||||

|

Re: Beating a Dead horse - 6v AC

|

||||

|---|---|---|---|---|

|

Home away from home

|

LOL Turbopackman i get your point, but for the same race that built the internet and got to the moon...we find 6V AC impossible. I have too much $$$ wrapped up in 6V on this car to convert UNLESS the cost to make a somewhat reliable 6v system exceeds the cost to convert to 12 AND replace the 6V parts i have (namely that pertonix kit at $100). Plus, i like to be different. Even if i don't build the system, just want to know it's out there if i decide to.

I think the trunk mounted electric motor driven option is out, i think i'd need like 24 volts or more. After all that work and price, might as well go 12 V.

Posted on: 2010/1/10 17:18

|

|||

|

||||

|

Re: Beating a Dead horse - 6v AC

|

||||

|---|---|---|---|---|

|

Home away from home

|

Read this then convert to 12V and be done with it. This guy makes a LOT of good points on the 6V a/c issue.

Posted on: 2010/1/10 17:32

|

|||

|

||||

|

Re: Beating a Dead horse - 6v AC

|

||||

|---|---|---|---|---|

|

Home away from home

|

Did come across that but he misses a few points:

-AC was invented before 12v was standard in cars and worked great (came across a guy with a mopar always on compressor that he said was one of the best AC systems he ever played with) -There were 6v compressor clutches. Availability is the only issue, and finding the applications. -Not all 6 volt systems are "poor old won't start while compressor is pumping break down"...mine is excellent. Car starts, runs, idles great, lights bright, voltage and amps there for the taking. More than enough for a good fan and plenty of accessories. -I don't expect like new AC performance...something vintage looking and vintage performing, like my half way working windshield defroster and crappy reception AM radio. Cooler air is great, but even with 12v I still wouldn't put an electric fan on the condenser, etc. -Honestly, it'd be as easy to convert this car to a chevy motor and be done with it. 12 volts, lots of power, tranny with sane ratios and take off. Cheap available parts for any option you desire. But i like the charm (like taking belts off or other issues you wouldn't do today for maintenance) and the look of vintage. I know they say you have to find your own line for the "when have you modified too much" issue, and adding an AC compressor for me isn't too much, 12v is. The most i think i'd do is add the second alternator and 12v circuit when it comes to wiring. The car is just working too well the way it is to replace bulbs, motors, etc. The most important issue here is....it's a challenge! It doesn't cost much to play around, and if we come up with a solution, how many 6V car hobbyists will be excited! Also, we forget, it was done once reliably before 12v came out and people enjoyed cool air. All we have to do is retrace out steps.

Posted on: 2010/1/10 17:45

|

|||

|

||||

|

Re: Beating a Dead horse - 6v AC

|

||||

|---|---|---|---|---|

|

Home away from home

|

I never said anything about putting a crapolet engine in your car.

As for 6V a/c systems, here's your best bet:

Posted on: 2010/1/10 17:51

|

|||

|

||||

(21.74 KB)

(21.74 KB)