|

Re: 29 packard 626 wheel shimmie

|

||||

|---|---|---|---|---|

|

Home away from home

|

wheel shimmie update I was able to work on the car a good bit today I checked everything mentioned and a few more things.I also checked the wheels for being bent they where also ok . I took the tie rod ends apart and found the sockets that go around the ball have actully wore the housing away and some one had tried to shim them tighter. also found something else the pins and bushings that go through the spring trunion and rear spring mount of the front spring are wore very bad. I was wondering if anyone reproduced these.also I tried to drop the front axle down and found the left side would not come down the shock was almost completely siezed up so I guess I have to send them somewhere. I hope fixing these areas will solve my problem. I have very little time to work on the car do to working 65 hours a week manditory

Posted on: 2012/4/15 11:38

|

|||

|

||||

|

Re: 29 packard 626 wheel shimmie

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Sorry to hear of your findings, but not surprising. Years of neglect and perhaps the assumption at some point that the Bijur was a novelty and not really essential and thus not maintained - seen it too many times.

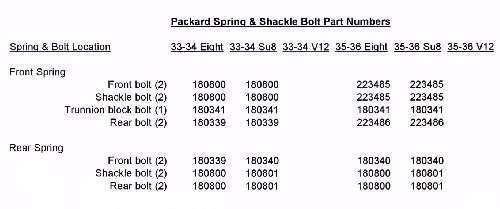

Spring shackle bolts properly drilled for Bijur lubrication are available from Bruce Blevins; as I recall he offers both stainless and tool steel. For this application stainless would not be the best choice. Check your parts book first and note which shackle bolt came from where - they are NOT all the same; there may be as many as 4 or 5 different drilled passage patterns dependent on oil flow routing. I don't believe Bruce offers the bushings but there is nothing unique about them and they are easily made from bronze round stock if you can't find them in a good spring shop, or perhaps even places like McMaster, MSC, etc.; I wouldn't use brass. For shock rebuilding, good results have been reported for Apple Hydraulics in the East and Five Points out west. PS - just to demonstrate the point on how shackle bolts are different to accomodate oil paths, here's some data for 33-36 8-cylinder models.

Posted on: 2012/4/15 11:53

|

|||

|

||||

|

Re: 29 packard 626 wheel shimmie

|

||||

|---|---|---|---|---|

|

Home away from home

|

Dear 29tons:

It is important to differentiate high speed from low speed shimmy. High speed shimmy is usually a tire related problem, while low speed (25-35 mph) indicates a suspension problem. Given this problem showed up suddenly, if you moved wheels around you may have created a problem. However, that frozen shock absorber is definitely a problem. Oh, and if you go back to 1925, that Bijur system is even more elaborate, but the king of Bijur is certainly Rolls-Royce. They had Bijur oil points by the dozen and stuck with the manual pump right through to the Cloud II.

Posted on: 2012/4/15 12:50

|

|||

|

||||

|

Re: 29 packard 626 wheel shimmie

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Since the Bijur system was costly and complex and I think mostly found on high end models, question is what did the lower price cars without it do.

Assume grease gun type equipment and lube was not generally available then so was that the need for Bijur or is that a wrong assumption and there is a different advantage. Sometimes wondered when you guys discuss Bijur related issues if low cost cars just did not have as many places needing attention or the driver had to use an oil can every morning or the car had to be disassembled to service with bear grease and pig fat or some such.

Posted on: 2012/4/15 13:26

|

|||

|

Howard

|

||||

|

||||

|

Re: 29 packard 626 wheel shimmie

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Since the Bijur system was costly and complex and I think mostly found on high end models, question is what did the lower price cars without it do.

Grease fittings and oilers, and lots of them. And later, for Packard beginning in 1937, the rear springs became mounted in rubber and the mechanical brake linkage was gone so the need for it diminished. The advantage - to do automatically (with the later Bijurs) or daily (earlier Bijur) what many drivers neglected to do at proper intervals - chassis lubrication. Last US car to use Bijur was, I believe, 1956 Lincoln. The Bijur has been credited with saving many a chassis from expensive repair.

Posted on: 2012/4/15 15:04

|

|||

|

||||

|

Re: 29 packard 626 wheel shimmie

|

||||

|---|---|---|---|---|

|

Home away from home

|

There dose not seem to be a parts manuel listed for a 1929. Also in the winter I did have all wheels off the car at one time but I guess there is no way to know for shur which wheels were on the front they are all the same. I see no difference in the wheels or wear patterns the tires are in near new condition. Thanks for all the replys I just hope I do not loose the whole summer trying to solve this.

Posted on: 2012/4/15 15:56

|

|||

|

||||

|

Re: 29 packard 626 wheel shimmie

|

||||

|---|---|---|---|---|

|

Home away from home

|

29 Tons, I had the same problem on all my shackle and spring bolts on the 733 as well. The hardened steel bolts were all worn and pitted with rust and the brass bushings were also worn, some of them as bad as 1/16" out of round. I bought an extra used set from a guy in California however these too were worn and so I had to replace all the bolts and all the bushings. I bought them all in one kit from Max Merit for about $950. It's not too difficult a proceedure but make sure to buy or borrow a good adjustable 3/4" reamer. After the new bushings are pressed in to the springs and frame horns you will have to hand ream them all. If you have access to a lathe I would have them all reamed or bored out .002" oversize before pressing them in to place.

Good luck Todd

Posted on: 2012/4/16 11:54

|

|||

|

||||

|

Re: 29 packard 626 wheel shimmie

|

||||

|---|---|---|---|---|

|

Home away from home

|

thats good to know the pin and bushing at the trunion pivit was about 3/8 of inch total wear so bad that when I turned the left front wheel with my hands you could see the trunion and back part of the spring twisting sideways. I never saw a trunion like this on a car before. Maybe thats the over engineered part

Posted on: 2012/4/16 17:32

|

|||

|

||||

|

Re: 29 packard 626 wheel shimmie

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The trunnion block is quite effictive at minimizing shimmy. Nothing over-engineered about it in my opinion, actually a rather clever bit of engineering which Packard allegedly stumbled across quite by accident.

3/8 slop in the shackle bolts is HUGE, I'll bet replacing them and the bushings will make all the difference in the world.

Posted on: 2012/4/16 19:01

|

|||

|

||||

(47.43 KB)

(47.43 KB)