|

Re: Adjusting the PB switching mechanism

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The primary thing that controls where in the space the motor stops is drag. There is a balancing act between a resistor and the friction brake on the end of worm. Turning one way, with thrust moving the worm away from brake, a resistor slows motor a bit. In the other direction with thrust moving the end play toward the brake, it is the friction. If it's reliably stopping at pretty much the same place in the space, doesn't overshoot or click more than once and then have to back up to get there, nothing needs to adjust on that part. There is enough play in things that anywhere in the center space is OK. If it backs up repeatedly, the adjustment is covered under anti-hunt adjustment.

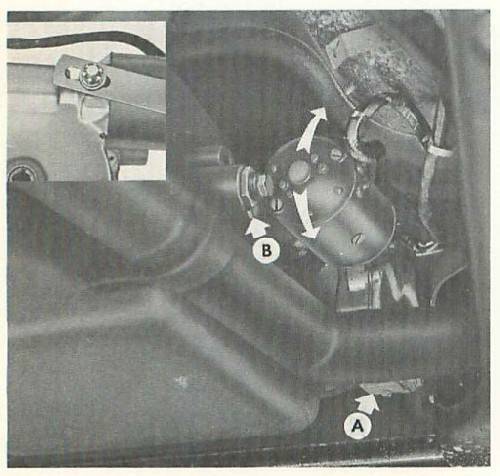

Once stopped, you need to verify the worm sector screw to trans shaft is tight. Then loosen the two bolts that hold the long strap and rotate the motor assembly up or down slightly to make sure the transmission valve is centered in the detent and then lock the bolts down. Motor end shouldn't move more than a very slight amount before you feel the detent limits on either side. Where you can run into trouble is if the pot metal lever in the transmission is loose on the shaft. Those threads stripping and setscrew loosening is a known issue and if that's the case, while the motor stops on a dime the valve may not be fully in position due to the slop in lever. That can lead to transmission problems. You can tell if that might be a problem if the motor end needs to move a fair amount before feeling detents. The adjustment procedures are documented in the Twin Ultramatic 56 supplement of service manual.

Posted on: 2012/4/11 10:01

|

|||

|

Howard

|

||||

|

||||

|

Re: Adjusting the PB switching mechanism

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Thanks. The reason I'm looking at this is because I have to occasionally push my desired button(s) more than once before it actually goes into that gear. It appears that it's stopping at pretty much the same place every time every time I push a button (not directly in the center of the space, but just barely missing the left edge of the contact segment). So I gather this is what you're saying I should consider doing:

1. Check, and ever so gently, turn the worm sector screw until it's tight if it's not already tight. Is the worm sector screw the screw that's at the end of the motor? 2. Loosen the two bolts that hold the long strap and then slightly rotate the motor assembly up or down to make sure the transmission vale is centered in the detent. Was your reference to the adjustments in the service manual pertaining to what has to be done when/if it's discovered that the pot metal lever in the transmission is loose on the shaft because of stripped threads or the setscrew loosening on its own?

Posted on: 2012/4/11 14:58

|

|||

|

||||

|

Re: Adjusting the PB switching mechanism

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The anti hunt adjustment needs to be done once in awhile. Symptom indicating need will be several clicks of the relay as the actuator hunts back and forth before stopping. If you don't have that, then that adjustment probably OK. Wouldn't hurt to check the detent now if it has been a long time or unknown history but normally it needs to be done only when the actuator is removed & reinstalled or if symptoms. You can tell if the lever inside has loosened though if you push up and feel a detent, bring it down and don't feel anything for several degrees. I forget how much play there is but not very much -- maybe 1/2 inch or so at end of motor. If someone has done it recently, maybe they can give a better answer. If it goes into gear with no hesitation and no strange symptoms from trans, it too is probably OK.

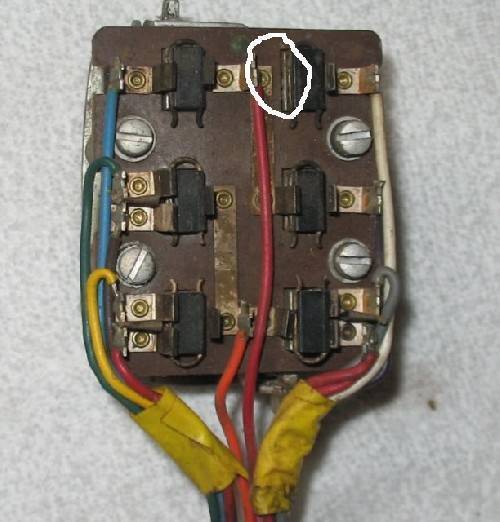

As to the pushbuttons, hopefully MrPushbutton will check in soon. He probably has seen the problem and has a ready answer but until he does-----. IMHO, if you have to push the button more than once, I would look at the PB assy first. It's easy to get to and there are several things that can go wrong. Here is a picture of the underside. This switch has a problem. Note in the circled area there is a contact missing. These are thin pieces of a spring bronze type material which flex and sometimes break at the bottom bend. In the case of the white wire or "H" button, it has broken on the common or feed side so that button will never work. It is possible for these to flex to the point of losing tension and not make good contact. The other issue is the horseshoe clips that make the actual contact. These can wear and even burn if there is a problem somewhere else. If it's more than one button acting up then would have to be something common to the buttons acting up. Pressure switch feeds 3 of the buttons and those are known to act up. The connector under dash has a habit of pins working or getting pushed loose so check all those are seated well. If everything good so far, then that leaves the finger(s) at actuator which might have worn a groove at the contact area or gotten hot and lost tension-- although if a problem with those, would think it would be very persistent or not work at all.

Posted on: 2012/4/11 15:19

|

|||

|

Howard

|

||||

|

||||

|

Re: Adjusting the PB switching mechanism

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Someone call?

What I have noticed on some "on-car" jobs I have been involved with, and seeing/hearing more about every day is the fact that between the gear-collar on the PB actuator and the valve body "plunger" that selects with gear the TU goes into is some linkage, and all of those items are subject to wear, and by now are worn. the connection from the actuator to the shaft is solid, as long as the set screw is correctly tightened, meaning first with the lock nut backed way off, so that you are sure the tapered portion of the set screw seats completely, then tightening the lock nut down. The arm coming off of the shaft pointing downward is a problem, it's soft pot metal and can weaken and wallow out after time. The two stamped steel yoke pieces and their pin (going into the above arm) can wear, and then everything is loose and subject to finding a happy medium by shifting back and forth from one direction to another to get to the proper gear. A good machinist could turn out an oversized pin, then the corresponing holes could be overbored to give a more precise fit. It is important to remember that the actuator does one simple thing, and that is all--it moves the gear-collar a specified number of degrees when actuated and after it comes to rest, that's all. It is a simple device with very few adjustments--the engineered drag of the anti-hunt function bening an important one. The trans has opportunities for compound slop into a valve body that I suspect wants a limited amount of variation. I notice on my test board (I have probably seen more of these things operate than anyone after 1956) that the stop repeatably at the same point, and that point will be to one side of the gap. That's fine, as long as it does so repeatably. what matters is the uniform angles of movement time after time. The contact segment is going to stop to one side of the gap, don't get hung up on it stopping in the center, the important thing is the uniformity. The angle of rotation is what matters, and the repeatability of the same.

Posted on: 2012/4/15 15:01

|

|||

|

||||

(30.66 KB)

(30.66 KB)