|

Re: 356 crankshaft weights question

|

||||

|---|---|---|---|---|

|

Home away from home

|

I consider Earl Sejrup to be one of the most knowledgable 356 rebuilders, and we have used him for several cars, and recommend him highly. In fact, he's building a spare 356 for us right now.

His phone number is 952-758-2360

Posted on: 2011/6/22 15:32

|

|||

|

West Peterson

1930 Packard Speedster Eight Runabout (boattail) 1940 Packard 1808 w/Factory Air 1947 Chrysler Town and Country sedan 1970 Camaro RS https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=4307&forum=10 http://aaca.org/ |

||||

|

||||

|

Re: 356 crankshaft weights question

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Perhaps he might be better advised to send it to a crankshaft shop that had done this successfully before. Here's how it's been described to me by a shop that does it; set up a milling machine to cut the welds and heads from the counterweight retaining bolts. Then lift the weights off, and then remove the remains of the bolts. Turn the shaft as needed.

They then make their own new retaining bolts with long extended shanks the diameter of the opening in the weight, and have them heat-treated. Bolt the weights back on TIGHT; cut off the excess bolt shank length, mill a bit of relief to the shanks into the recess in the counterweight, and then weld them up. Then balance. Don't forget to note which counterweight went in which position, I seem to recall they are not identical. Or Dave, if you get that call from Steve Babinsky who I referred to you the other day, ask him - he does this type of crankshaft on a regular basis.

Posted on: 2011/6/22 15:38

|

|||

|

||||

|

Re: 356 crankshaft weights question

|

||||

|---|---|---|---|---|

|

Home away from home

|

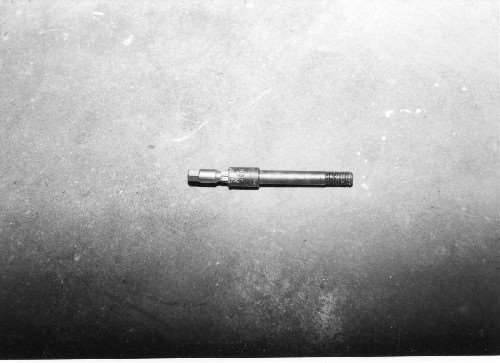

I used a spline type screw extractor to remove the bolts by carefully drilling a hole of the recommended size for the extractor in the center of the bolt. I broke a standard socket on the first try but was successful when I used an impact socket in the 5/16' size needed for the hex on the extractor.

The attached photos show the holes drilled in the bolts, extractor driven into a bolt, removed bolt with extractor still in place and the removed counterweights. For those who have never seen one of these crankshafts, removal of the counterweights is necessary for grinding the throws to undersize since the weights overlap the edge of the throws by about 1/16" Brian

Posted on: 2011/6/22 22:00

|

|||

|

||||

(108.51 KB)

(108.51 KB)