|

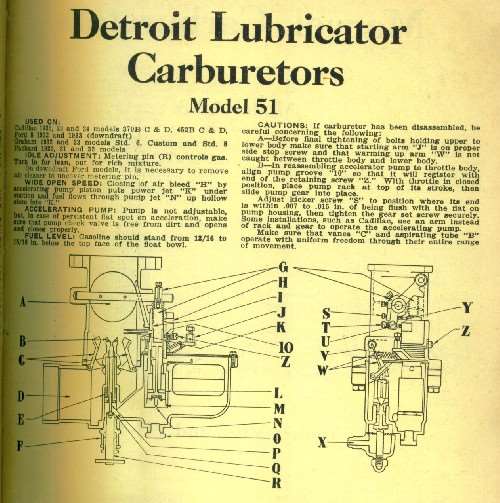

Re: 1930 Detroit Lubricator Model 51

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Have you tried the "search" function? I don't have a lot on the DL51 but I did post some original service information here a while back in response to a similar inquiry, and as I recall there was additional information posted by someone else.

And although they will no longer rebuild them (new ones are now available), you might talk to Daytona Parts who did rebuild them for years and they are quite knowledgeable about them. From the little first-hand experience, check the accelerator pump check valve, but also suspect would be warped vanes. Repro vanes were available for some time from (now deceased) Henry Yeska but I also heard comments that their quality was poor. There also is a man who does rebuilt the DL-51s, John Hardgrove. I understand the cost of a rebuild is about $1500+, no personal experience with him or his work.

Posted on: 2014/8/2 16:18

|

|||

|

||||

|

Re: 1930 Detroit Lubricator Model 51

|

||||

|---|---|---|---|---|

|

Home away from home

|

Posted on: 2014/8/3 16:08

|

|||

|

||||

|

Re: 1930 Detroit Lubricator Model 51

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks for the info,

Gene

Posted on: 2014/8/3 16:37

|

|||

|

||||

|

Re: 1930 Detroit Lubricator Model 51

|

||||

|---|---|---|---|---|

|

Home away from home

|

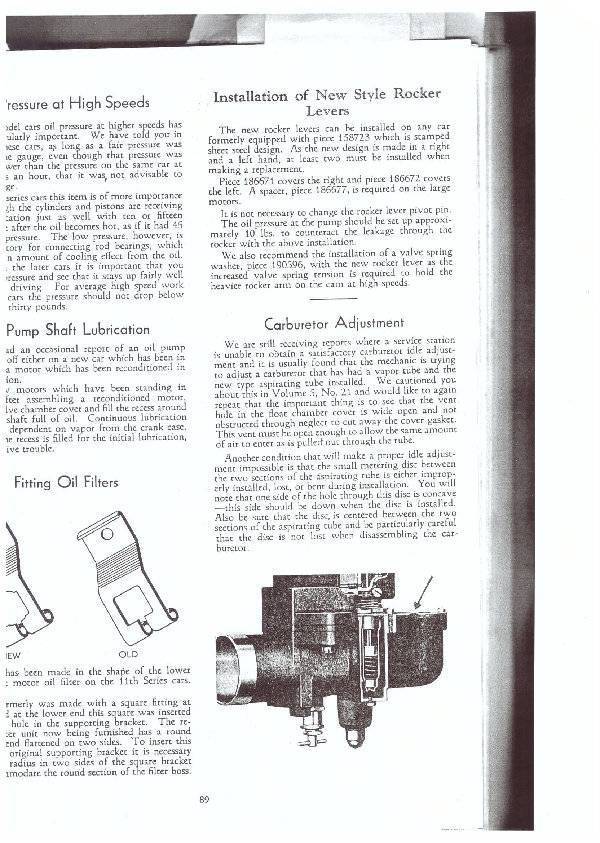

Just posting for future reference this bit from an AACA forum regarding the DL-51 aspirator and its infamous wafer:

forums.aaca.org/topic/107702-replacing-a ... del-51/?tab=comments#comment-469558 If one WISHES to remove the aspirator valve spring, it does require a special tool that has been out of production for about 77 years. However, one may be fabricated: (A) measure the inside diameter of the threaded area where resides the gland fitting for the adjustment screw. (B) subtract 0.010 inch, and turn a piece of steel approximately 4 inches long in your lathe to this dimension. ? CAREFULLY measure the center to center distance of the two small holes in the bottom of the aspirator valve AND the diameter of these holes. Subtract 0.002 inch from the diameter (D) Drill corresponding holes of the 0.002 inch diameter in the end of the 4 inch steel bar. (E) Insert steel pins of the proper diameter in the two holes. Tool is finished. Clamp the free end of the tool in a good vise on your workbench. Now set the carburetor bowl assembly on the tool (it doubles as a holding fixture for the bowl, and carefully rotate the top of the aspirator valve until the pins catch in the the holes. Now using an open end wrench, loosen BUT DO NOT REMOVE the aspirator valve. Place the bowl with the loosened aspirator valve in a large pan (a clean oil drain pan works well). Now carefully remove the 2 halves of the aspirator valve, the aspirator spring, AND THE TINY WAFER MAIN JET SANDWICHED BETWEEN THE TWO HALVES! Lose the jet, and the carb won't work. I would give you the dimensions, but "Detroit Lubricator" and "standard sizes" is an oxymoron. I have made several different tools for our own use. Going from memory, Packard used more than 30 different Detroit Lubriactor Carburetors. The need for this wafer has been verified by David McCredie who discovered the relevant section in a re-print publication of 7-12th Series Packard Service Letters. (BTW, A person need not make the tool above-described as David Frear of Packard Carburetors sells the tool.)

Posted on: 2019/6/23 14:18

|

|||

|

Rob

1930 Custom 8 Club Sedan |

||||

|

||||

(186.59 KB)

(186.59 KB)