|

Re: Head Torque

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

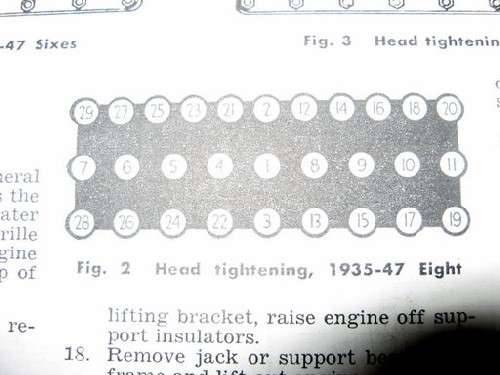

Couple of pic's from an old Motors Manual.

Tightening sequence for a 282 eight - sorry for the pic quality. And head stud torque is 63 lbs/ft

Posted on: 2009/7/1 6:02

|

|||

|

Mal

/o[]o\ ====  Bowral, Southern Highlands of NSW, Australia "Out of chaos comes order" - Nietzsche. 1938 Eight Touring Sedan - SOLD 1941 One-Twenty Club Coupe - SOLD 1948 Super Eight Limo, chassis RHD - SOLD 1950 Eight Touring Sedan - SOLD What's this?  Put your Packard in the Packard Vehicle Registry! Here's how! Any questions - PM or email me at ozstatman@gmail.com |

||||

|

||||

|

Re: Head Torque

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

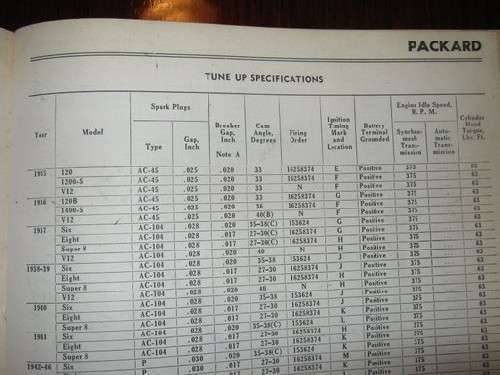

A 36 120 engine should be a 282, not a 288; it became a 288 in 1948 when they rationalized the bores of all 3 engine sizes to 3-1/2 inches.

Many folks do not use any sealant on head gaskets, yet I've always used the aerosol form of Permatex copper spray sealant with excellent results, and would suggest same. Torque in 3 steps, perhaps in the range of 30 lb-ft the first time, 50 the second time, and 63 the final time, and then after the engine has run for a couple of hours and is cool, retorque at least one more time. EDIT: Don't forget that the stud threads should be clean and dry to get a valid torque measurement. You can use a chaser die or a wire brush as you just want to remove carbon and rust, thread size is 7/16-20 as I recall.

Posted on: 2009/7/1 7:15

|

|||

|

||||

|

Re: Head Torque

|

||||

|---|---|---|---|---|

|

Quite a regular

|

SUPER ! Thanks for your quick help on this.

Posted on: 2009/7/1 7:16

|

|||

|

||||

|

Re: Head Torque

|

||||

|---|---|---|---|---|

|

Quite a regular

|

Hi - one quick tip here; you will want to torque head down again after a few hundred miles. In fact, a machinist who is also a Packard collector here told me I should re-check and re-torque ('39 120 - 282) a couple of times as the gaskets compress a fair amount.

Did mine in April with some great advice from these forum members and so far so good. Good luck with your project!

Posted on: 2009/7/6 20:37

|

|||

|

Steve Mackinnon

1939 Packard 120 Sedan (sold) 1940 Packard 110 Convertible |

||||

|

||||

|

Re: Head Torque

|

||||

|---|---|---|---|---|

|

Home away from home

|

G'day all, I would suggest that the head torque be checked with the engine warm. Alloy heads ( including Packard) are always done when stone cold but to my understanding Packard cast iron heads are initially set during assembly when cold then checked when warm. I would strongly suggest that the head tension be checked every few years, with a warm engine. best Regards Peter Toet

Posted on: 2009/7/8 4:43

|

|||

|

I like people, Packards and old motorbikes

|

||||

|

||||

|

Re: Head Torque

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I haven't checked the Packard service information for confirmation, but I've always been told that cast iron heads are torqued cold, and aluminum heads warm.

Posted on: 2009/7/8 7:05

|

|||

|

||||

(20.31 KB)

(20.31 KB)