|

Re: Bench testing my combination fuel pump vacuum question

|

||||

|---|---|---|---|---|

|

Webmaster

|

Have you looked at the fuel pump rebuild article here on the website. It will show you how everything is supposed to go together.

Posted on: 2009/8/29 23:26

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: Bench testing my combination fuel pump vacuum question

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

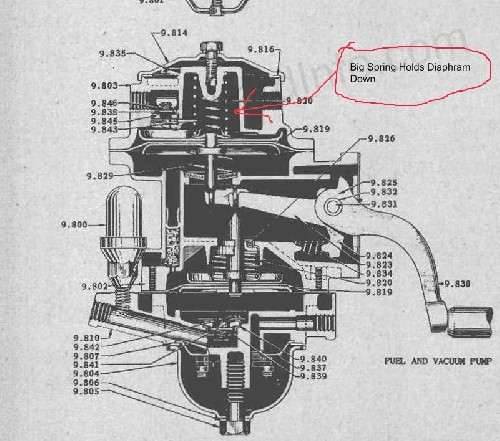

I did, actually I have looked at it several times, it gave me the inspiration to tear into mine. Looking it over, the vacuum pump must be a vacuum assist, because for the most part the "big" spring holds the diaphragm in a neutral position. It looks to me that if the engine vacuum is large enough to pull the spring, then the pump would "kick in". I am going to guess that my hypothesis that the pump was meant for full throttle operation is wrong. The pump is meant for when the engine is idle and the vacuum is the strongest. Must be a smooth idle thing.

Thanks,

Posted on: 2009/8/30 16:43

|

|||

|

||||

|

Re: Bench testing my combination fuel pump vacuum question

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Your assist theory is correct but pump is there for when the vacuum from intake manifold is low. The diaphragms move together but due to the springs, independently as the fuel side will sometimes not move at all or very little depending on how much and how fast the float is allowing fuel into carb. The springs pushing against the diaphragm also determine the output fuel pressure of 4-5psi.

The determining factor when the assist takes over or helps is the valving which works just as the fuel side does. When manifold vacuum is stronger, air is essentially just sucked through the pump and assist has little to do. When under open throttle or any low manifold vacuum conditions, the assist side is stronger and valving only allows exhausting into manifold side and suction from wiper side. While not as much volume or as strong as manifold vacuum, it is still sufficient to keep wiper motor moving --although slower. Specs for those vacuum pumps in general were 8 1/2 inches hg minimum at 180 rpm and 12 inches hg maximum at 1800 rpm. As you see, lower than manifold but still sufficient.

Posted on: 2009/8/30 17:11

|

|||

|

||||

|

Re: Bench testing my combination fuel pump vacuum question

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

I swiped an image of a similar pump from the literature that shows the big spring that has me confused. It looks to me that the vacuum works against the spring, causing the pump to engage when the vacuum is the highest.

I am sure that mine is assembled correctly, I may have to take it on faith that the Packard Engineers designed it correctly. I is bugging me though. Thanks for the specs, I will install the pump on the motor and verify that it works using your data.

Posted on: 2009/8/30 22:24

|

|||

|

||||

|

Re: Bench testing my combination fuel pump vacuum question

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

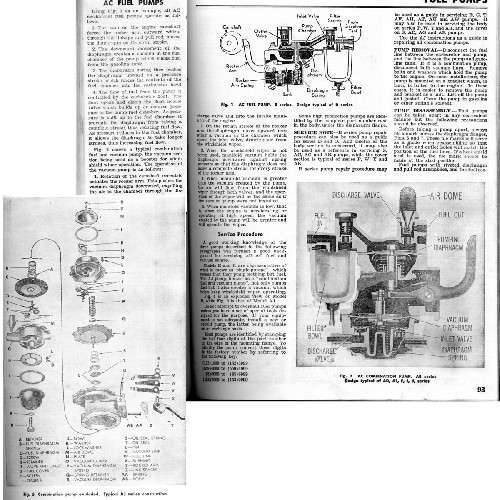

Here is a brief description of vacuum section operation from a Motors Manual. Think you might have hit the spring purpose/workings in post #3 above. Illustration keyed to description probably of wrong model as I don't know what 22nd used. Threw in one from AJ series as typical since it was similar to what you posted.

Posted on: 2009/8/31 12:05

|

|||

|

||||

(71.88 KB)

(71.88 KB)