|

Re: Fuel pump insulators

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Last set I made I turned from nylon.

Posted on: 2014/1/16 12:28

|

|||

|

||||

|

Re: Fuel pump insulators

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

Thanks. I hadn't considered nylon but maybe I should. I notice it's strength is excellent but temp rating is only 165. Does anyone have any idea of the temp range of the block in that area. I know it wouldn't get close to that while running but just curious how hot that area gets after a long run and then sitting and soaking after the engine is turned off.

Posted on: 2014/1/16 12:49

|

|||

|

Howard

|

||||

|

||||

|

Re: Fuel pump insulators

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Howard, if concerned about nylon, you could also turn them from Teflon rod - a bit more costly as a raw stock but it is easily available and machines quite nicely, even better if it's frozen first. As far as I know, the nylon ones I made are still happily in service and it's probably been a dozen years.

Posted on: 2014/1/16 13:39

|

|||

|

||||

|

Re: Fuel pump insulators

|

||||

|---|---|---|---|---|

|

Home away from home

|

Just a guess, but it's shouldn't be much more than the temperature of the oil going through it, maybe up to 100+ max.

Phenolic is good at high temperature. It's used in brake lining. Since it's a spacer, unfilled teflon may not be the best material as it tends to flow under pressure. Some glass filled nylons are much higher temperature and what I think they mold intake manifolds from. Glass filled rod stocks are available in both materials.

Posted on: 2014/1/16 14:16

|

|||

|

||||

|

Re: Fuel pump insulators

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

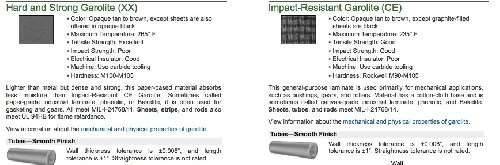

Leaning toward the XX grade Garolite. It's good to 265 & already the right size in tube form. Shouldn't need more than a touchup to make it fit. Doubt with the pump sandwiched between the bolts there will be much to worry about with impact strength. Nylon tube is inexpensive so might order a length of that as well to compare and to have on hand.

Posted on: 2014/1/16 14:36

|

|||

|

Howard

|

||||

|

||||

|

Re: Fuel pump insulators

|

||||

|---|---|---|---|---|

|

Home away from home

|

After thinking more about this I find I misread the post, it's the fuel not the oil pump but the analysis is ok. I checked on oil temps and the recognized approach is between 15-30 deg over the coolant. So if it's a 160-180 stat, you're safe at 190-210F operating design and with a 7 lb cap it's 250F max., The pump is external and fuel is flowing so some of the heat will go out as a safety margin.

I couldn't figure out why those were in there when I rebuilt my pump. I don't see any real reason for them, except the casting hole was larger than the bolt used. Must of been someone's idea of quieting or vibration isolation/dampening. These type isolators should be available, but thankfully, that's one I didn't need to run down, so no help there. There's some fuel pump rebuild guys out there you might try. Viton also comes to mind but probably not in this shape.

Posted on: 2014/1/16 19:34

|

|||

|

||||

|

Re: Fuel pump insulators

|

||||

|---|---|---|---|---|

|

Home away from home

|

Howard, I used nylon washers and tubing and a thick pump to block gasket. Did not safety wire the bolts. Should check them.

(o{}o)

Posted on: 2014/1/16 22:39

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: Fuel pump insulators

|

||||

|---|---|---|---|---|

|

Home away from home

|

I checked the temperatures with a non-contact thermometer after a long drive in my Packard. The block is roughly the water temperature (160F). Obviously it could go higher (220F) if driving on a hot day in a parade.

Posted on: 2014/1/17 10:36

|

|||

|

Fred Puhn

|

||||

|

||||

|

Re: Fuel pump insulators

|

||||

|---|---|---|---|---|

|

Home away from home

|

You can take this for what's it's worth, but I think we are reading too much into this. The Fuel Pump is mounted flat against the block. So as far as reducing vibration, I don't think so. Plus if a Packard engine is vibrating that much there is a problem some where else. And as far as heat transfer from the block, I wouldn't worry about it because the pump is hanging off the block in the open air. I just replace a Fuel Pump and when I took it off the engine I found one of the spacers missing. After much hunting and research, I came to believe that all they are, is spaces so that when you re-install the Fuel Pump it is aligned correctly since the holes are bigger than the bolts. So for my missing insert, I just used a piece of cardboard.

Just my two cents. Wes

Posted on: 2014/1/17 11:25

|

|||

|

||||

(52.36 KB)

(52.36 KB)