|

Re: Huge Miss

|

||||

|---|---|---|---|---|

|

Home away from home

|

Bully for you!!! That's an undertaking, but you seem to have kicked its arse. If next weekend's deal comes together, I may be inheriting a valve issue myself. We'll see.

I did rebuild a M1 rifle earlier this year and the recoil spring came out in 4 or 5 pieces. That rifle is a 1943 model. I guess the steel got old and tired in each case.

Posted on: 2024/10/6 15:28

|

|||

|

If you're not having fun, maybe it's your own damned fault.

|

||||

|

||||

|

Re: Huge Miss

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

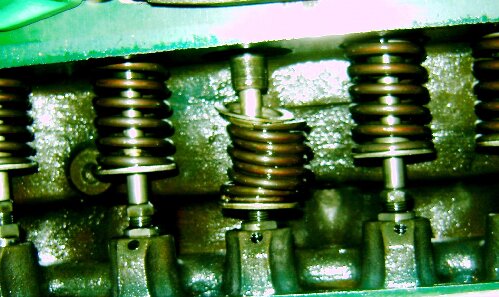

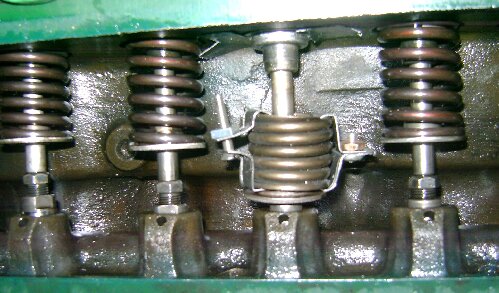

Bob J for a great description as well as the visual documentatiom. I'm sure this will help another Packard owner to fix a similar problem. Bob J for a great description as well as the visual documentatiom. I'm sure this will help another Packard owner to fix a similar problem.For what it's worth, probably very little, when I rebuilt my 120 engine about 15 years ago found that one of the valve springs was broken. Although it appeared to be running well up to that time, just old and worn out, like the owner. My spring had only one break, maybe that made a difference?

Posted on: 2024/10/6 16:09

|

|||

|

Mal

/o[]o\ ====  Bowral, Southern Highlands of NSW, Australia "Out of chaos comes order" - Nietzsche. 1938 Eight Touring Sedan - SOLD 1941 One-Twenty Club Coupe - SOLD 1948 Super Eight Limo, chassis RHD - SOLD 1950 Eight Touring Sedan - SOLD What's this?  Put your Packard in the Packard Vehicle Registry! Here's how! Any questions - PM or email me at ozstatman@gmail.com |

||||

|

||||

|

Re: Huge Miss

|

||||

|---|---|---|---|---|

|

Home away from home

|

I forgot to note this was a "new" valve spring. I cannot tell if it was NOS from a shelf from the 50's or if it really was a newly manufactured one. It was cello wrapped and packed from the vendor. Stuff just happens, a bad spot when drawing the wire or something can happen anytime so I thought I would post this to help anyone else that finds themselves in this situation, definitely not restricted to any make or model of engine, but the L heads do require this type of tack vs our OHV brethren.

Also to your point Oz, it had run a bit rough at one point before the catastrophic one, so it may have survived the one break until the penny dropped on the second one?! Bob J.

Posted on: 2024/10/6 17:52

|

|||

|

||||