|

1951 288 Screw On Oil Filter and Bracket

|

||||

|---|---|---|---|---|

|

Home away from home

|

I'd like to use a screw on oil filter and bracket on my 1951 288. Any filter P/N's recommended?

Posted on: 2019/5/20 19:11

|

|||

|

||||

|

Re: 1951 288 Screw On Oil Filter and Bracket

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I don't recall anyone ever posting they had done that mod except on a V8 when adding a full flow filter to the Olds oil pump conversion so no help on numbers.

Summit has a relatively inexpensive kit with a mount for the spin on that looks like it would be able to fit in the same area as the Packard filter. Probably need to make some kind of conversion piece out of flat stock to mate the wide Packard holes on the head to the narrower adapter holes.summitracing.com/parts/sum-g4985-1/overview/ Summit has other adapters not in kit form that might also work but you need to buy the fittings and lines separately. Here is one that also accepts the PH8A filtersummitracing.com/parts/der-35709/overview/ It would appear on any of the adapter kits the filter ports are very large compared to what is on the car. If I were doing it I think I would disregard the rubber hoses and fittings that come with the kits and buy brass fittings or adapters and maybe do metal tubing to make the lines look more stock but that may be overkill. Not sure what kind of fittings would be needed or are available to get from the large filter ports on the adapters to the 1/8 NPT out of the engine no matter what hose or tubing you use.

Posted on: 2019/5/20 19:56

|

|||

|

Howard

|

||||

|

||||

|

Re: 1951 288 Screw On Oil Filter and Bracket

|

||||

|---|---|---|---|---|

|

Home away from home

|

Why would this require a flow restricter?

Posted on: 2019/5/21 18:47

|

|||

|

||||

|

Re: 1951 288 Screw On Oil Filter and Bracket

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Packard used a partial flow or bypass filter system where about 90% of the output flow from the pump was used for engine needs and about 10% went to the filter. Over time the entire amount of oil in the pan is filtered but not all flow goes thru the filter before going to the engine as is done in the full flow system the spin on filter was designed around.

The amount of oil going thru the postwar Packard filter is determined by some small holes in the center exit pipe of the filter canister. In prewar filters the input and outlet locations are reversed and the center tube is the input. In those filters there is a specifically sized orifice in one of the fittings at either end of the filter supply tube. The valve lifters get their oil supply from the same pump outlet port as the filter. Since you are going to be adding a filter without any restrictions built in, in order to ensure adequate flow keeps going to the lifters from that single supply port you will need to restrict the amount that can get to the filter. Without the restriction, the filter's large surface area would probably be easier for oil to flow thru than keep the lifter galley pressurized and flow thru tiny clearances so most of the oil would go to the path of least resistance. Easiest way to add a restriction would be to place a plug of solder in the adapter fitting going to the new filter inlet and then drill a hole thru the solder plug. On the engines that had the orifice in a fitting, the opening was 5/64.

Posted on: 2019/5/21 19:21

|

|||

|

Howard

|

||||

|

||||

|

Re: 1951 288 Screw On Oil Filter and Bracket

|

||||

|---|---|---|---|---|

|

Home away from home

|

Agreeing with Ross, the original design oil filter is among the easiest and cleanest of filters to replace. The elements are readily available from NAPA. Their filter number is 1080 and probably other manufacturers still make them also.

Posted on: 2019/5/21 20:50

|

|||

|

Don Shields

1933 Eight Model 1002 Seven Passenger Sedan 1954 Convertible |

||||

|

||||

|

Re: 1951 288 Screw On Oil Filter and Bracket

|

||||

|---|---|---|---|---|

|

Home away from home

|

Right now there is only a tube connecting the output to the input. If I take this tube off and replace it with a same-sized tube route to the oil filter, I don't see where the oil flow will increase. If there is some flow restriction, it must be in one of the adapters.

Posted on: 2019/5/24 7:06

|

|||

|

||||

|

Re: 1951 288 Screw On Oil Filter and Bracket

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

As I mentioned in another post, the restriction is built into the canister on postwar filter assys. As you can see from this 55-6 assy, there is a small hole in the center outlet pipe which restricts the flow. Other postwar filter assys have the same although there are differences in the location or in the number and size of the holes. The end result is the same -- only a small portion of the available oil supply is allowed to pass thru the filter.

With the built in restriction, the amount of flow does not depend on the size of the tubing supplying these filters and believe me, the stock 1/4" tubing is capable of supplying a considerable amount of oil in a hurry -- word of advice: do not leave the filter lid loose and start the engine. If you remove the factory filter and install your full flow spin on unit you need to provide some kind of restriction to limit flow thru the new filter. That will keep enough pressure and volume at the oil supply port in the block to provide adequate flow to the lifters and prevent them from being starved. If the engine has solid lifters it could possibly get away with a reduced oil supply -- provided enough volume is flowing to reach those lifters on the ends for lubrication. If they are hydraulic, there would not be enough flow and pressure to keep all of them pumped up and noisy lifters would be the result. The easiest way to add a restriction would be to provide a small orifice in one of the new fittings that you will need to install to adapt the new filter ports to the different size tubing.

Posted on: 2019/5/24 8:55

|

|||

|

Howard

|

||||

|

||||

|

Re: 1951 288 Screw On Oil Filter and Bracket

|

||||

|---|---|---|---|---|

|

Home away from home

|

The motor has mechanical lifters and has no filter. I don't think it ever had one.

Posted on: 2019/5/24 13:16

|

|||

|

||||

|

Re: 1951 288 Screw On Oil Filter and Bracket

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

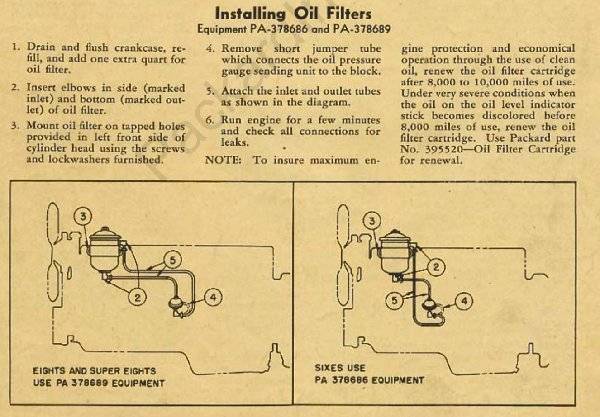

Very possibly not on the 200. Filters were optional as were hydraulic lifters for the 200 but was generally included on the other models which were higher end and more likely to have had hydraulic lifters purchased. If the hydraulic lifter option had been bought on your engine it would probably have had a filter. On your earlier post you mention removing a small tube and installing the filter. If you mean the small curved pigtail connecting the bottom port on the block containing the sender to the port just above it, that small tube is the supply for the lifter gallery. It is not ideal from a consistency standpoint, but without having hydraulic lifters you could install the spin on filter inline and leave it unrestricted. All oil going to the lifter gallery thru the filter first was an accepted practice on the first version 288/327 solid lifter blocks. Those engines did not have a separate filter return port. Even with a clogged filter there was generally adequate flow to provide lubrication for solid lifters. The big issue was with hydraulic lifter cars where inadequate volume and pressure caused by clogged filters would result in noisy lifters. On possibly 23rd series 50s but definitely by the 24th 51 models when hydraulic lifters became more the norm for all models they added a return port to drop the filtered oil directly into the crankcase. All the 288/327 engines from then on kept the pigtail in place feeding the lifter gallery directly from the supply port. The filter was supplied from one side of a 4 way fitting on the bottom supply port and the lifters kept their supply via the pigtail on the other side of the fitting. Here is an illustration showing an earlier filter install on a solid lifter 22nd series engine. You could do the same using your unrestricted spin on.

Posted on: 2019/5/24 14:23

|

|||

|

Howard

|

||||

|

||||

(124.94 KB)

(124.94 KB)