|

Re: BigKev's 1937 115-C Convertible Coupe

|

||||

|---|---|---|---|---|

|

Webmaster

|

Well shoot. The piece of kiln dried ash I have is neither wide nor thick enough to cut the rear bow out of.

I've have to see if the local hardwood place has a bigger chunk ash that will work.

Posted on: 2023/10/19 18:03

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: BigKev's 1937 115-C Convertible Coupe

|

||||

|---|---|---|---|---|

|

Home away from home

|

It might be worth noting that mine is original and is one straight piece that has been steam bent to its shape.

I am worried if you simply cut the form from the plank it will create a very weak spot through the bend area due to the grain, even in the hardwood. It is rather structural and under some stress under the canvas and may be unstable causing warp or worse if any impacts occur with the top up. Can you source board feet of material and have a cabinetmaker or other established craftsman steam in the bends? Bob J.

Posted on: 2023/10/20 10:29

|

|||

|

||||

|

Re: BigKev's 1937 115-C Convertible Coupe

|

||||

|---|---|---|---|---|

|

Webmaster

|

Bob noted and understood.

I can see that the original was steam-bent from a single piece. I don't have the equipment to do that. I have also noticed that others have made this from 1/4" strips that could be easily bent and glued together around a form. But I am going to give my "composite" bow a go first. If it doesn't work out, then I will probably hand it over to a shop that can steam-bend one. But since I already have this wood, I want to take the low-budget route first. The main horizontal section will be strong as it travels with the grain. It's the vertical pieces that go across the grain that would be weak. Since I don't have enough thickness anyway to cut from a single piece, I will make it from a layered "sandwich" of pieces. The vertical sections will be a composite of wood in two different grain directions. Between that and copious wood glue, it should make it much stronger than if I just cut it from a single piece of wood.

Posted on: 2023/10/20 10:55

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: BigKev's 1937 115-C Convertible Coupe

|

||||

|---|---|---|---|---|

|

Home away from home

|

Kevin - a thought on your process that keeps with the low budget approach. You could sandwich a thin layer of plywood between the two layers you mentioned.

The plywood would give you strength in the grain both directions and provide three layers for more glue surface area.

Posted on: 2023/10/20 10:59

|

|||

|

||||

|

Re: BigKev's 1937 115-C Convertible Coupe

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

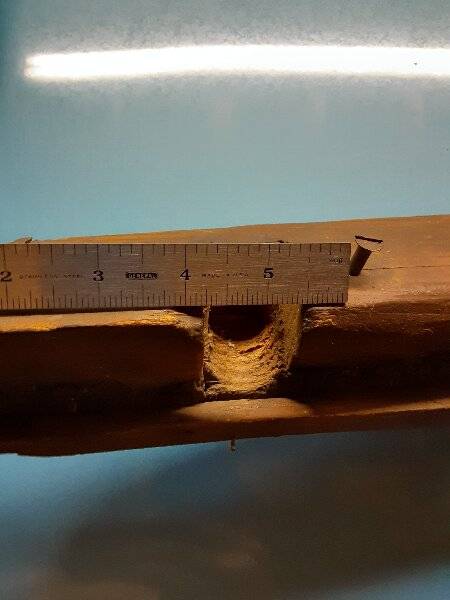

Not sure if you are still interested in pictures of the front header bow as I see in post #1070 you have it attached. I have my original header bow and if you need more pictures just let me know. A question I have is I see in the "Production Packard" manual by Dar Kuehl he mentions in section 8.4 that the bow was originally painted dawn gray. My bow is definetly the original bow and was never painted, not that it's a big deal but I'm trying to keep mine as original as posible.

Attach file:  e68e8925-a1eb-48d2-9726-2af826ff6eb8.jpg (106.38 KB) e68e8925-a1eb-48d2-9726-2af826ff6eb8.jpg (106.38 KB)  04250aaf-e3a2-4f08-83d1-ec8b2720f841.jpg (123.82 KB) 04250aaf-e3a2-4f08-83d1-ec8b2720f841.jpg (123.82 KB)

Posted on: 2023/10/20 16:37

|

|||

|

||||

|

Re: BigKev's 1937 115-C Convertible Coupe

|

||||

|---|---|---|---|---|

|

Webmaster

|

Thanks for the photos. Those are helpful!

Posted on: 2023/10/21 21:07

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: BigKev's 1937 115-C Convertible Coupe

|

||||

|---|---|---|---|---|

|

Webmaster

|

Rought pieces cut out. These are cut oversize to give me lots of meat to wittle down to shape. This is being made from three layers glued together. Center and end end prices oriented to give strongest grain directon where needed. So 3 layers of 3 pieces each. So 9 pieces today. Each layer joint is offset.

Anyway here is the first glue up the center pieces of layer 1 and 2. Once that glue is cured, then I will glue center piece 3 to the stack. Then the end pieces get glued in. Once everything is cured, then the shaping will begin.

Posted on: 2023/10/21 21:13

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: BigKev's 1937 115-C Convertible Coupe

|

||||

|---|---|---|---|---|

|

Webmaster

|

Layer 3 glued.

Posted on: 2023/10/22 8:48

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: BigKev's 1937 115-C Convertible Coupe

|

||||

|---|---|---|---|---|

|

Webmaster

|

Final pieces and clamping in progress. 22 clamps in use!

Posted on: 2023/10/22 20:21

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

20231020_102209 Large.jpeg (108.71 KB)

20231020_102209 Large.jpeg (108.71 KB)