|

Re: The Duchess Project: 1940 Super 8 Convertible Sedan

|

||||

|---|---|---|---|---|

|

Home away from home

|

Joe, The governor unscrews. Greg

Posted on: 2014/2/26 12:07

|

|||

|

||||

|

Re: The Duchess Project: 1940 Super 8 Convertible Sedan

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The governor unscrews. Packard had a special stubby wrench but if you have the top access off, perhaps a regular length will work. Believe the size is 1 7/16" but it has to be thin -- believe the limit is around 3/8" or less in thickness.

Later wrenches which could also work on the prewars were the same size but had the handle bent to clear the cross brace. Attach file:  (15.74 KB) (15.74 KB)

Posted on: 2014/2/26 12:21

|

|||

|

Howard

|

||||

|

||||

|

Re: The Duchess Project: 1940 Super 8 Convertible Sedan

|

||||

|---|---|---|---|---|

|

Home away from home

|

Joe,

I would recommend that you have both of your rear springs serviced at the same time so you will have equal springing/support on both sides of the rear of the car. If you have had a weak spring the other spring has had to support more weight etc. Servicing the one weak spring will only start the same problem again from opposite side. Hope this makes sense, not sure if I am explaining properly.

Posted on: 2014/2/26 13:01

|

|||

|

Stephen

|

||||

|

||||

|

Re: The Duchess Project: 1940 Super 8 Convertible Sedan

|

||||

|---|---|---|---|---|

|

Home away from home

|

REAR SPRINGS: Thanks, Stephen. Will do while Duchess is down. More to take apart! Whoo-hoo! Get ready for more questions, guys.

OVERDRIVE GOVERNOR: Indeed, Howard, I found the post of the fellow you were helping on the AAC website describing the tool he made which is exactly as you spec'd. 1-7/16" 3/8" thick max stubby or bent handle. Someone else's post suggested trying slip-joint pliers which worked for him. The 1-7/16 wrench I looked at last night is way thick, so I'll try the pliers if I can find a thin pair. DRIVE SHAFT: I used a wire wheel brush on my buffer to remove all the paint and rust, so now have to break out the paint booth setup since the cross members have to come out, too, and now rear springs. Noted on the universal joint that 5 of the bolts have 7/16" heads and 3 have 1/2" heads. The 1/2" are much harder to get off because, besides being very tight, are too large to allow the round end of the wrench full access. So I will be looking for some 5/16" 3/4" bolts with 11/16" worth of thread with 7/16" heads.Restoration is eternal. QUESTION: What do you need to bench test a small electric motor? I don't like using the car battery. And I'm actually asking about a motor from the Jag, so 12V, positive ground. Unfortunately the Jag forum is not quite the same as this. The one guy who responds to my posts sends everything out.

Posted on: 2014/2/27 10:03

|

|||

|

||||

|

Re: The Duchess Project: 1940 Super 8 Convertible Sedan

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I bench-test small electrical motors using a battery trickle charger. Mine has a max output of 10 amps so there's not much in the way of small motors that I can't test with it.

Posted on: 2014/2/27 10:08

|

|||

|

||||

|

Re: The Duchess Project: 1940 Super 8 Convertible Sedan

|

||||

|---|---|---|---|---|

|

Home away from home

|

Joe,

You can always buy a cheap Harbor Freight wrench and grind it thin. That's what I've done when needing a thin wrench in the past. Rich

Posted on: 2014/2/27 10:15

|

|||

|

||||

|

Re: The Duchess Project: 1940 Super 8 Convertible Sedan

|

||||

|---|---|---|---|---|

|

Home away from home

|

I have Helpers to pull the clutch.

Posted on: 2014/3/14 14:58

|

|||

|

||||

|

Re: The Duchess Project: 1940 Super 8 Convertible Sedan

|

||||

|---|---|---|---|---|

|

Home away from home

|

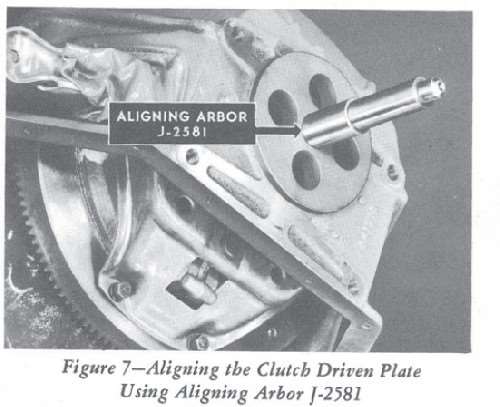

Putting in the rebuilt clutch and transmission.

Do you know where I can get a clutch alignment tool/dowel?

Posted on: 2014/4/28 12:38

|

|||

|

||||

|

Re: The Duchess Project: 1940 Super 8 Convertible Sedan

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Finding one like that with the pilot inside the bellhousing probably won't be easy or cheap but you can get universal tools at many places that will do the job. You just need to have the pilot side and plate inside snug with minimal slop and make sure the end sticking out the bellhousing is fairly well centered.

The downside to modern tools is Packard used a size pilot on the seniors that is not quite the same as others use today. If one of the premade pilot inserts does not fit well, you would have to do something to take up the slack in order to get a non sloppy fit so the plate will be well centered. Many have used broomsticks or dowels or have raided the socket wrench drawer to get a socket of the proper diameter and wrapped tape around to make them fit. I made my own by turning the end of an extra piece of 1 1/8" phenolic rod down to size. For my 2106 it worked out to be .960 to fit inside the bearing and 1.100 for the part that fits inside the clutch plate.

Posted on: 2014/4/28 13:27

|

|||

|

Howard

|

||||

|

||||