|

Re: 1940 Manual OD Trans Synchro

|

||||

|---|---|---|---|---|

|

Home away from home

|

Well, that is certainly unique. When running in 3d, the synchro ring and the dog shifter ring are both engaged on the input shaft and the drive is straight across that joint between the input shaft and the mainshaft. So,I am at a loss as to how there is enough relative motion to make enough heat to "braze" the synchro ring to the input shaft (since the synchro is bronze faced.

I have seen trannies with heavy damage caused by end play issues. Failure of the input shaft or main shaft lock ring would do that. I have also seen heavy damage caused by the omission of the round-section spacer ring that is supposed to be slid onto the end of the mainshaft after the synchro assy is installed.

Posted on: 2015/6/23 5:19

|

|||

|

||||

|

Re: 1940 Manual OD Trans Synchro

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thank you. This is very helpful, Ross. What are the "end play issues?" The shop said there was about a 1/4" play when they reassembled it with the new main shaft and they reduced it to 1/32nd (or something small like that...).

The repair manual says No perceptible endplay. So what can happen when the endplay is not right? Right, meaning? Did you mean if it was set too tight the synchro would always be engaged? I was in overdrive when all this happened. In OD on the freeway, up the avenue at 40mph hitting every light, so no stops, and slowing down on the drive through the golf course (where it happened). The core shaft is being sent back to us so we can check it against the new (rebuilt) main shaft that was in the car when this happened.

Posted on: 2015/6/23 10:54

|

|||

|

||||

|

Re: 1940 Manual OD Trans Synchro

|

||||

|---|---|---|---|---|

|

Home away from home

|

I meant: there should hardly be any end play of the input shaft--I would think .005 or so. That would be the play of the balls in the races. The snap rings should not allow any movement of the bearing in the case or the shaft in the bearing.

The mainshaft assy complete should have about the same end play as that is controlled by the bearing at the rear of the case and a similar arrangement of snap rings. On the mainshaft itself, there should be no perceptible movement of the gears axially if it has been rebuilt correctly as those bearings should all be preloaded by the rolled-on ring right after the spine that the synchro assy slides on. Which end play did the shop reduce to 1/32? I don't get that one. Running in overdrive or out should not make a scintilla of difference.

Posted on: 2015/6/23 12:10

|

|||

|

||||

|

Re: 1940 Manual OD Trans Synchro

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Ross is far better to diagnose this than I am, but 1/32 of end play anywhere sounds hugely excessive.

Posted on: 2015/6/23 13:58

|

|||

|

||||

|

Re: 1940 Manual OD Trans Synchro

|

||||

|---|---|---|---|---|

|

Home away from home

|

My memory failed me. 1/32=.03125. It was probably 3/1000ths. 0.003

Was I off by a order of magnitude? Does that sound any better?

Posted on: 2015/6/23 14:05

|

|||

|

||||

|

Re: 1940 Manual OD Trans Synchro

|

||||

|---|---|---|---|---|

|

Home away from home

|

I have some experience with basket case transmissions and reviewing transmissions that were put together with parts missing and what not.

The first step in the process is to review symptoms. I handled a V-12 once that had no synchro action. Upon disassembly a restorer installed the spacers on the main shaft in the wrong places. There was no endplay problem. When you put one of those things on the bench the first thing you check is the end play. It should be recorded. So if the only symptom was the willingness to spend money, when new parts are installed the process should stop if the endplay doesn't match what it was to begin with. I agree with Ross as far as an endplay issue. Probably what happened was a partial hop out in which the synchro brake ring was acting as the driving member. You may not have noticed because of the OD free wheeling effect. The manual says to use selective sized rear shaft bearings and selective sized snap rings to eliminate end play. (As measured using a dial indicator.) That stuff is not available from the Packard plant, so if there is a preload problem then the bearing can be milled. Otherwise shims can be cut by hand or using a die cutter. Anyway, this project should have stopped with the endplay problem because 1/4 inch indicates a part is missing or terribly wrong.

Posted on: 2015/6/23 15:32

|

|||

|

||||

|

Re: 1940 Manual OD Trans Synchro

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks much, Tim. I know you're a stickler for doing it right. I will pass this on to the shop, which has been very cooperative, considering the Duchess occupies a lift while everything gets sorted out.

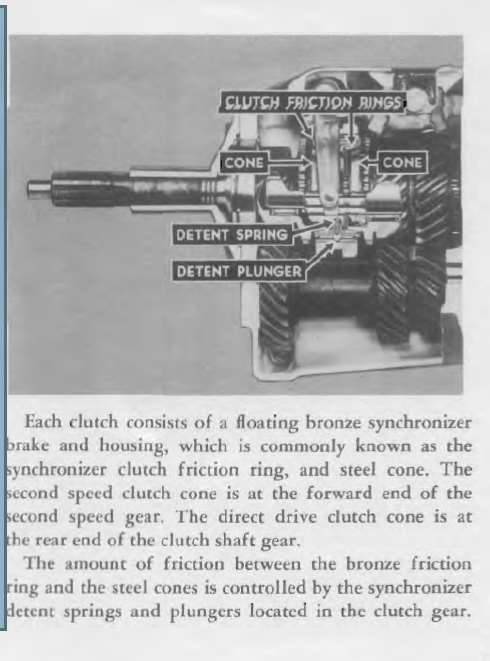

This reference from the 1948 trannie/OD training manual hasn't been mentioned. I wonder if a faulty detent spring or plunger could braze a synchro on to the input shaft. "The amount of friction between the bronze friction ring and the steel cones is controlled by the synchronizer detent springs and plungers located in the clutch gear." Attach file:  (50.67 KB) (50.67 KB)

Posted on: 2015/6/23 16:08

|

|||

|

||||