|

Re: Rear Wheel Bearing Replacement

|

||||

|---|---|---|---|---|

|

Home away from home

|

Hi Packard 1948;

Here's my two cents on the wheel bearing subject. ? Be sure to down-load the rear axle service manual and familiarize yourself with the bearing servicing procedures. ? With a new bearing in-play the likelihood of a different shim stack dimension is quite probable. Have a source ready to procure the specific shim(s) that you will need. ? Select a shop that is familiar with the shimming process of opposed tapered bearings, and is willing to await the appearance of a new shim if needed. Do not rotate the pinion or 'other' wheel when the subject axle is removed (see the precautionary remarks in the shop manual about the thrust block). If at all possible, avoid removing both axles at the same time. You can prep both sides by removing the wheels and hubs, but leave the backing plate on the opposite side until you have the subject axle and backing plate reinstalled. ? The Packard axle or any other that has a tapered hub, needs attention after some amount of use. The initial torqueing of the axle nut pushes the hub onto the axle, or if you like draws the axle into the hub; however after about 100 miles the tapered interface re-positions itself and the axle nut will have less apparent torque. I believe the relaxation of the nut torque is the root cause of the all too familiar 'broken axle' failure there the nut and treaded portion of the axle ends-up in the hub cap. ? The shop should be aware that you intend to return in X days to have the axle nut torque rechecked. Avoid the urge to over tighten the first time to forgo the repeat visit. Although the specified axle nut torque is quite high, avoid the urge to use impact equipment. ? There are hub/drum pullers that have removable 'legs', and can be configured to use either 3, 4, or 5 units. Home Depot (and perhaps others) carry rubber 'under sink' plumbing elbows that fit the outboard portion of the hub quite well, and they have a worm clamp to make a tight seal. You can use the elbow to create a reservoir for penetrating oil (50/50 mix of acetone & AFT). I'm told that time helps with this job. With some amount of tension on the puller and some amount of penetrating oil, the hub will release 'all by itself'. I was thinking of some restraint from the leaf spring to the hub if I was ever in a position where I was out of the shop with tension of the puller. I agree with Owen that this is a 'pretty routine' procedure. Other than a hub puller, a shop press is the only special equipment needed to remove and replace a wheel bearing. Given tool rentals and shops that would press off and on a bearing, I would recommend an 'at home' repair. My '48 broke an axle on the road, but after a short ride on a flatbed tow truck it was back home. The repair was paced by awaiting the UPS driver to bring me parts. You can buy Timken rear bearings at NAPA. Since most stores do not carry this item you'll wait a few days. The shimming process begins on page 30 of Section 2 of the '48 shop manual (that's hard copy page 30 / PDF page 32). I do have however some concern with step 6 as presented by the Packard authors, If there have been parts replaced (bearing/axle/banjo housing) I would conduct numerous free clearance checks as the bolts and nuts are 'gradually snugged-up'. My concern is that you may have an insufficient amount of shims and some amount of bolt and nut tightening will be with zero bearing clearance. My advice would be do not continue to tighten the bolts and nuts if 'free clearance' cannot be confirmed. Do agree step 6 is OK if we were only re-lubing the axle bearing or providing brake maintenance. As a practical matter both wheels of the car should be off the ground. We need to push the 'other' axle as far out board as possible to conduct the clearance check. I welded two nuts together, one threaded to fit the Packard axle, and one to fit my slide hammer. With a good amount of steady pressure I 'bumped' the axle that I was working on toward the center of the car. The steady pressure and the slight 'bumping' should have transferred through the thrust block and into the other axle shaft. I would also recommend that the clearance check be conducted initially with a dry bearing, . . . I found the lack of grease allowed me to 'feel' the limits of the axle travel. Once I was confident that the clearance was close I lubed the bearing and reassembled with the same shim stack. Once you review the shop manual it should be clear that you are setting the clearance for both bearings, that is, if you shim and achieve 0.004 clearance on the 'subject' side, then the 'other' side has the identical clearance. The shop manual precaution about 0.050 is to keep the thrust block somewhat centered . . . see the last statement in step 9 of the process. In operation as side forces are applied to the car, as in cornering, both axles and the thrust block act as a singular unit, and one axle bearing is supporting both the weight of the car (on that side) and the side force. The internal clearance of that bearing has been minimized. The other bearing is reacting only the weight of the car (on its side), and the clearance is maximized to the value you shim adjusted (as modified by the temperature of all of the parts). The design intent would be to have the minimum amount of bearing clearance to accommodate all thermal operating environments. A ball bearing design rear axle avoids the thrust block, and precision installed clearance adjustment. Don't let the shared precautions of the forum stop you from conducting this procedure at home. As Owen said, 'it's pretty routine'. Owen's tool appears to be quite similar to the Packard special tool mentioned in the manual. I used a dial indicator when I was overly cautious re-tightening the backing plate bolts, that is, step six, which gave me 'both hands free' while pushing and pulling on the axle while I was trying to determine if I was in the ballpark. dp

Posted on: 2016/5/8 14:30

|

|||

|

||||

|

Re: Rear Wheel Bearing Replacement

|

||||

|---|---|---|---|---|

|

Quite a regular

|

Hello,

What is the OD / ID on the shims? I need to check the rear bearings / axle end play on my 1948 and would like to have a shim kit on hand prior to starting (if easily possible). Also, are the shims readily available from auto parts stores? Thanks! Tom in KC

Posted on: 2016/5/20 11:04

|

|||

|

||||

|

Re: Rear Wheel Bearing Replacement

|

||||

|---|---|---|---|---|

|

Home away from home

|

IIRC, you can use the gaskets as a template for the shims. No, they are not available at parts stores. You probably have enough shims with the ones now on the car. It would be easy enough to make an additional shim if one is needed from shim stock.

(o{}o)

Posted on: 2016/5/20 11:09

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: Rear Wheel Bearing Replacement

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I don't know about availability of shims, when I need one I just cut them with scissors from thin steel shim stock. Helps to have a good hole punch for the bolt holes.

Posted on: 2016/5/20 11:10

|

|||

|

||||

|

Re: Rear Wheel Bearing Replacement

|

||||

|---|---|---|---|---|

|

Home away from home

|

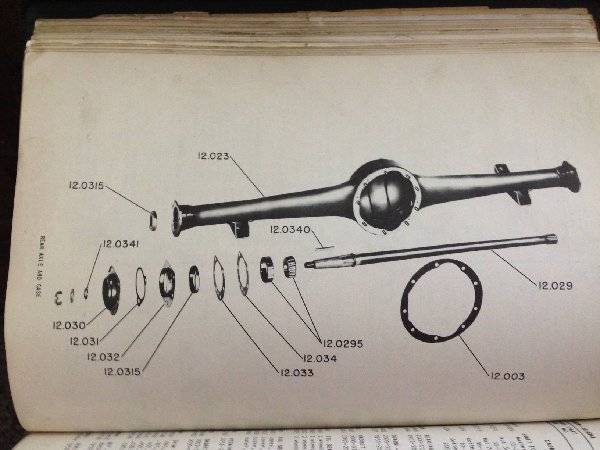

Tom, a picture is worth a 1k words. Shape of shims is different than gaskets.

(o{}o)

Posted on: 2016/5/20 11:20

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: Rear Wheel Bearing Replacement

|

||||

|---|---|---|---|---|

|

Quite a regular

|

OK, thanks! I'll use one of the existing shims as a template.

Regards, Tom

Posted on: 2016/5/20 16:23

|

|||

|

||||

(154.93 KB)

(154.93 KB)