|

Re: Torsion Level System

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

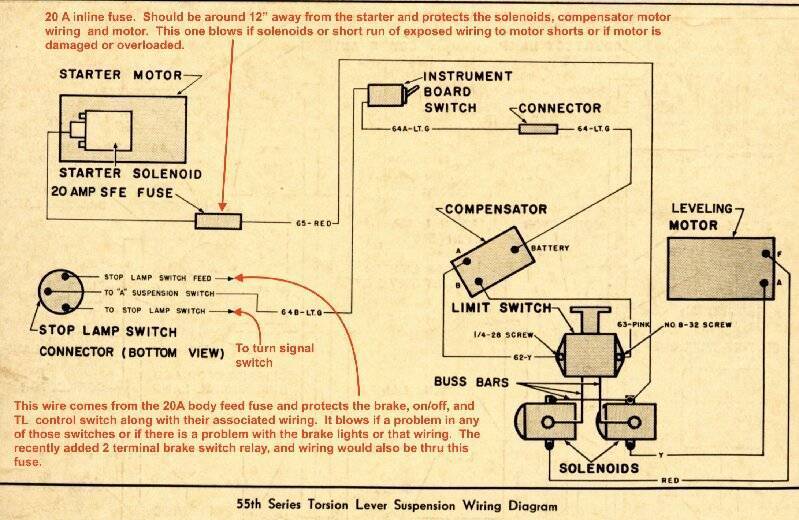

On TL systems there are two fuses -- in a 55 there is the 20 amp inline fuse that protects the compensator motor and solenoids. The brake switch, on/off switch, and control switch along with their associated wiring is protected by the 20 amp body feed fuse in the fuse block under the dash.

For the wires to burn it could be a short in the TL wiring or a switch but it could also be a short in any of the wiring running to the brake lights. The brake light wire also goes thru the turn signal switch and loom so you would need to check there too. One place others have had shorting problems is in the trunk. Some have had objects bang against the tail light housings and smash a wire into the socket and others had something fall into the sort of trough at the very rear of the trunk floor and wear thru the loom as it crosses over to the right side. 56 changed the TL fusing slightly. They went to a 30 amp inline for the motor and solenoids and removed the components formerly protected by the body feed fuse to a separate fuse. They added a 7 1/2 amp fuse supplied from the primary 30 amp TL fuse to protect the switches and brake lights. Getting a car level may not put the bars in the proper position where you can get at the plugs. If you can support the car with jackstands under the frame, then by using a floor jack you can raise or lower the rear axle and move the short bars and the transverse bar to a position where it can mate with whatever position in its range you can run the compensator lever. You should then be able to connect the two back up without major disassembly. If it popped out the plug on the end of the transverse bar must have really been loose and others could be the same. You will probably need a drag link socket and your ratchet to work in the narrow space and have leverage to tighten them properly.

Posted on: 2021/8/16 10:00

|

|||

|

Howard

|

||||

|

||||

|

Re: Torsion Level System

|

||||

|---|---|---|---|---|

|

Home away from home

|

Howard thanks for the quick response.

FYI - I had replaced the three wire brake switch with one of the 2 wire kits about 4 years ago. The 20A fuse on the red wire that goes to the starter would that have been near the starter or closer to the leveling motor because I can't seem to find it (Source of melt down??)?

Posted on: 2021/8/16 10:49

|

|||

|

||||

|

Re: Torsion Level System

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The 20 amp inline fuse should not be affected nor be the cause of the wires you mentioned as being burned. If the wiring is stock, those wires would be protected by the 20 amp body feed fuse and I am surprised that one did not blow.

There is a splice in the main loom just off the body feed fuse where the brake switch gets its feed. Identified as wire 13-P on the main 55 wiring diagram. I would check the amp rating of the body feed fuse and if there is any chance the melt continued maybe check the main loom under the dash for any suspicious areas. Here is the 55 TL diagram showing which fuse protects which components.

Posted on: 2021/8/16 11:34

|

|||

|

Howard

|

||||

|

||||

|

Re: Torsion Level System

|

||||

|---|---|---|---|---|

|

Just popping in

|

Hello.

I am having an issue with my 55. The front end seems to sink slowly as it sits in the garage. When I jack it up the front end stays high until I push on it which causes it to sink back down. The leveling system has 2 wires dangling so don't know what's going on there, but either way, shouldn't the torsion bars keep it somewhat level?

Posted on: 2021/9/4 4:49

|

|||

|

||||

|

Re: Torsion Level System

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The torsion bar suspension settles out about the car's center of gravity. Check out the T-L primer in the FAQ section of this website.

The electromechanical leveling system is what returns it to level. It's possible that 2 dangling wires have rendered your levelizer inoperative.

Posted on: 2021/9/4 8:18

|

|||

|

||||

|

Re: Torsion Level System

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

...............but either way, shouldn't the torsion bars keep it somewhat level? Think back to your younger days at the playground and then of the car body as sitting on a teeter totter at the exact center. Remember what happened when a larger kid was on one end of the teeter-totter. His size always made the smaller kid raise up in the air. If the weight difference between kids was a large amount the smaller kid would raise and never touch the ground. If they were closer in size it was still easier to raise the smaller kid than the larger but with extra work they could sort of balance and make the teeter-totter move. If the large kid moved a bit closer to middle or the smaller kid could move farther way from middle or suddenly gain some weight they could both balance and move the teeter without much effort. In this case, the long bars supporting the car are the teeter-totter and the engine and front of the car is the larger kid. The compensator and short bars do the same thing as if the smaller kid could suddenly gain a few pounds. In a bare bones car things are almost at balance but if the car has a lot of accessories like power steering and power brakes or AC, all that extra weight in the engine compartment and drivers seat area tends to make the front end heavier so the front wants to drop down. The compensator and short bars work to balance the car by twisting and adding load on the rear to try and match the front -- same as if you gave the smaller kid something heavy to hold. If the car is loaded down with passengers and luggage, the rear is heavier so in that instance the short bars twist the other direction to subtract rear weight. Basically the level system works by sensing the amount of twist at the middle of the long bars and having that twist work the control switch to determine which direction the car rear needs to move. Hanging wires are never good and in a 55 there could only be a couple of places where disconnected wires would affect the leveling components. That would be the wires connecting to the brake light switch which would be almost directly inward of the left front wheel or to the control switch or motor which would be more under the drivers seat. While it is obviously not the best option, there are some with inoperative level systems that sort of make do by carrying extra weight such as a sack or two of sand in the trunk to balance out the engine weight. That will halfway work on a level surface but in driving, the braking or acceleration force will unbalance the car again so one end of the other will be heavy until a long stretch of level road or steady driving is maintained long enough for the car to balance. The number and placement of passengers will also affect the weight distribution.

Posted on: 2021/9/4 9:48

|

|||

|

Howard

|

||||

|

||||

|

Re: Torsion Level System

|

||||

|---|---|---|---|---|

|

Home away from home

|

I was able to work on the TL system this past week. I examined the 12 volt supply (red wire) to the TL system, which came from the starter. The insulation was completely melted over its entire length and was still intact as far as the copper goes. There was no fuse or fusible link to be found in the wire. The wires that merged into the bundle (Red & Lt Green) had their insulation also melted.

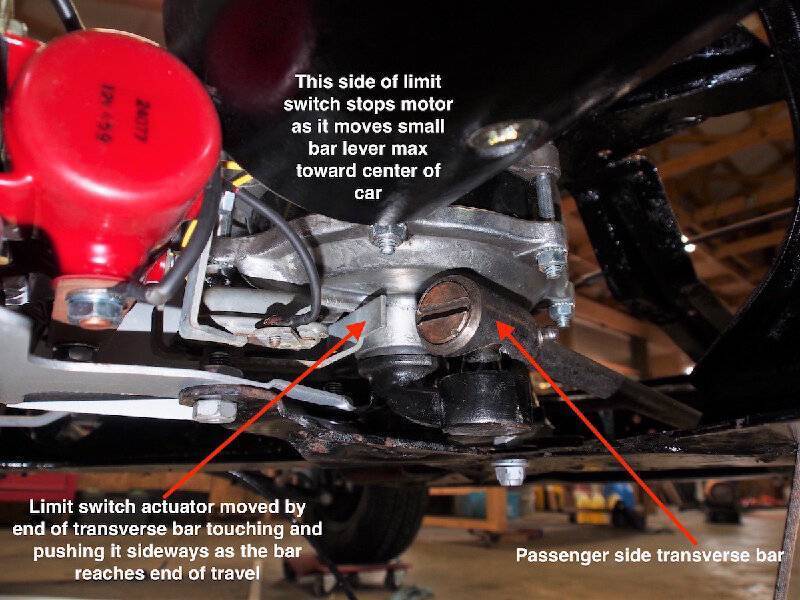

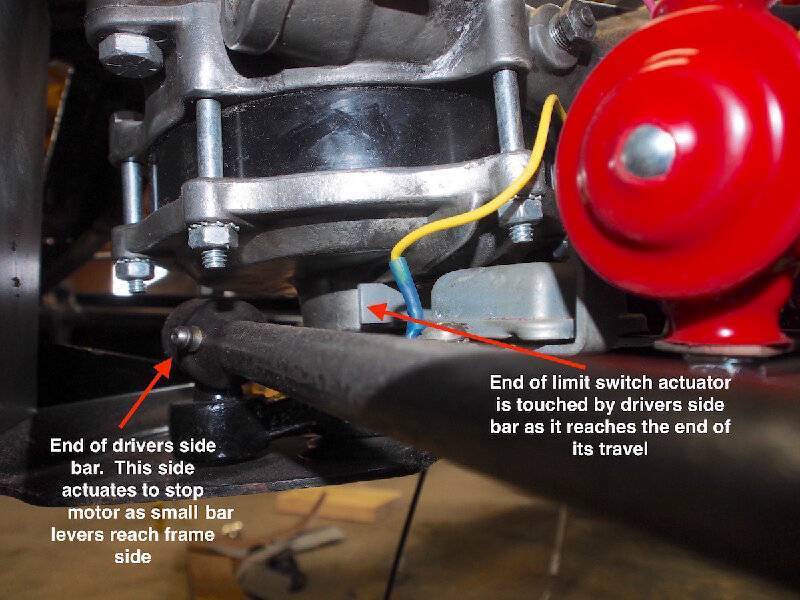

When I went to run the replacement red wire from starter the nut was extremely tight. Therefore, I decided instead of pushing the issue risking damaging the starter I would get 12 volts from the battery. I installed a fuse (20A) right at the battery and replaced the rest of the damaged wires. The arm that slipped off the Compensator (levelizer) bar was reinstalled. The system was tested by shorting out terminal “A” or “B” to ground. While doing all of this, I notice that the limit switch appears to be incorrect in that I do not see a way for the tabs to be engaged by any mechanism on the system (see photos). It would seem that the tabs on the arm should be in the opposite direction. Should the tabs point towards the gear box or in the opposite direction?

Posted on: 2021/9/20 13:18

|

|||

|

||||

|

Re: Torsion Level System

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The orientation appears to be correct and the limit sw lever is supposed to be pushed by the wide end of the transverse bar. This happens as the end of the bar passes center and the rotation of the compensator lever starts to pull the bar back in toward the switch lever. It is supposed to happen just before the narrower portion of the bar is pulled inward enough to touch the compensator assy or the levers connected to the ends of the short torsion bars the transverse bars connect to push out far enough to touch the frame rail or are pulled inward toward the center of the car enough to be almost straight.

If there is any chance you have a completely original and very early production 55 or one that might have had an early NOS limit switch a vendor found laying on a shelf installed as a service item after Packard went away, the first run of limit switches had a lever that was too short. If the transverse bar absolutely can not touch the switch lever enough to activate the switch you might measure the length and see if the switch is the later version with the corrected lever.packardinfo.com/xoops/html/downloads/STB/55T-2.pdf Here are a couple of photos Stewart took of his 55 after rebuilding the assembly. Attach file:  Viewed from rear of car copy.jpg (134.48 KB) Viewed from rear of car copy.jpg (134.48 KB)  Viewed as looking from drivers side door copy.jpg (118.59 KB) Viewed as looking from drivers side door copy.jpg (118.59 KB)

Posted on: 2021/9/20 13:50

|

|||

|

Howard

|

||||

|

||||

|

Re: Torsion Level System

|

||||

|---|---|---|---|---|

|

Home away from home

|

The bar is 2 1/16". Here are 3 more photos. As you can see when viewed from the rear, the bar is ~1/2" to short in order for it to contact bar. When actuated in the other direction, the bar is way to short in order for it to hit the shoulder on the bar.

I've included a picture of the solenoid bracket with the limit switch. I don't see anything wrong here or am I missing something? Attach file:  Viewed from Rear.JPG (288.42 KB) Viewed from Rear.JPG (288.42 KB)  Viewed from front.JPG (290.64 KB) Viewed from front.JPG (290.64 KB)  Switch-Mounting.JPG (207.84 KB) Switch-Mounting.JPG (207.84 KB)

Posted on: 2021/9/20 15:16

|

|||

|

||||