|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

I had 6 pieces (the 4 side scripts and the 2 tail light "V") on the wife's '55 Caribbean gold plated at Kustom Krome in November 2019. Total cost was $395 with lifetime warranty against peeling/flaking. I'll add that they were all in decent shape without any pitting.

I took pictures of the 6 items and emailed them. He provided a quoted on that. I'm happy with the quality and service.

Posted on: 2021/9/14 9:55

|

|||

|

||||

|

Re: Stewart

|

||||

|---|---|---|---|---|

|

Home away from home

|

I love it when a plan comes together!

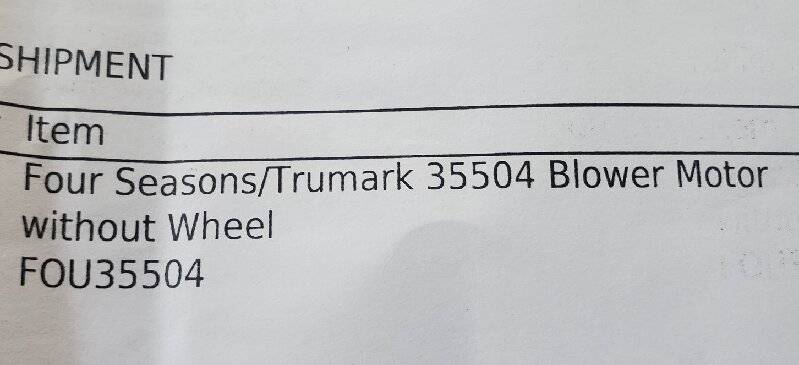

I ordered that fan motor from Amazon and it arrived this morning. The faceplate and the fan fit perfectly. I can make a rubber gasket that separates the motor and the faceplate and the screws appear to be adjustable so I can make them longer if needed. The best part of this is that it only cost $40, shipping and all. I don't know how much it would have cost to have the original motor rebuilt but I saw one of our online sources had them for $175. Attach file:  NameAndModel.jpg (83.15 KB) NameAndModel.jpg (83.15 KB)  FacePlateFits.jpg (178.28 KB) FacePlateFits.jpg (178.28 KB)  NewFanMotor.jpg (168.98 KB) NewFanMotor.jpg (168.98 KB)  TheSquirrelCageFits.jpg (233.89 KB) TheSquirrelCageFits.jpg (233.89 KB)

Posted on: 2021/9/15 10:29

|

|||

|

Stewart Ballard

|

||||

|

||||

|

Re: Stewart

|

||||

|---|---|---|---|---|

|

Home away from home

|

Great going. It's nice to see something not made in China.

It's sad to hear about Kustom Krome. They were nice to work with.

Posted on: 2021/9/16 9:47

|

|||

|

||||

|

Re: Stewart

|

||||

|---|---|---|---|---|

|

Home away from home

|

I had no idea that mounting one of the front fenders would end up being a 3 man job.

I want to just want to hang the front fenders temporarily to get them off the floor and to do some work that I'll cover in another post. I have that top bolt, at the firewall in place but it just will not dropping into place at the radiator frame. I thought maybe the fender support (that connects to the rad. frame) was bent but its not. Is there a trick to this? Do I have the radiator frame facing the right direction?

Posted on: 2021/9/20 18:26

|

|||

|

Stewart Ballard

|

||||

|

||||

|

Re: Stewart

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The radiator cradle looks to be correct. Is there anything on the frame rail such as a bolt in a hole or something on the suspension A arm pieces that got caught and keeps the bottom of the fender from pulling in? The inner fender should be fairly close - 1/2" or less to the generator when generator is at max outward belt adjustment position.

Posted on: 2021/9/20 18:35

|

|||

|

Howard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

There is nothing in the way. I tried bolting it up front or back. First the rear bolt and then the front bolts. When I remove the rear both and mount only the front bolt to the radiator support all the holes inside the fender match up to the frame. However the rear bolt is off by about 3/4 to an 1 inch.

When I remove the front bolts and only bolt it at the rear, nothing lines up. I am afraid I am going to have to loosen all the body mounts and try to rock the body forward to make up that distance. The holes through the body may have enough play to allow it.

Posted on: 2021/9/20 18:57

|

|||

|

Stewart Ballard

|

||||

|

||||

|

Re: Stewart

|

||||

|---|---|---|---|---|

|

Home away from home

|

I am going to try and clarify my post from last night's.

First the problem in this post and the next post may contain a possible solution. Image 1 - shows the front of the fender in place with a bolt in the front only. There are no other bolts in the fender at this time. Image 2 - show the bolt holes inside the fender well. The holes in the frame line up as expected. Image 3 - shows the rear, body, bolt hole. It is off by about an inch. This tells me that the body may be too far back. Image 4 - I removed the bolt from the front and now the fender is bolted only to the firewall at the rear (I forgot to take a picture of that) as you can see the bolt holes inside the fender do not align as they did before. The frame holes are about 1” forward. That just confirms my theory (to me anyway) that the body is too far back as all the holes except for the firewall bolt aling up when bolted in the front. Attach file:  OnlyBoltedAtFront.jpg (128.19 KB) OnlyBoltedAtFront.jpg (128.19 KB)  InsideFenderWell_LinesUp.jpg (256.09 KB) InsideFenderWell_LinesUp.jpg (256.09 KB)  RearBoltDoesNotLineUp.jpg (101.37 KB) RearBoltDoesNotLineUp.jpg (101.37 KB)  InsideFenderWell_DoesNotLineUp.jpg (241.16 KB) InsideFenderWell_DoesNotLineUp.jpg (241.16 KB)

Posted on: 2021/9/21 15:46

|

|||

|

Stewart Ballard

|

||||

|

||||

|

Re: Stewart

|

||||

|---|---|---|---|---|

|

Home away from home

|

How would the body have gotten too far back? There isn't that much slop in the body mount holes, is there?

-Kevin

Posted on: 2021/9/21 16:20

|

|||

|

||||

|

Re: Stewart

|

||||

|---|---|---|---|---|

|

Home away from home

|

A possible cause and solution to the problem.

Many, many moons ago, someplace in my blog, I made the decision to purchase a conversion plate from Bendtsen’s to allow me to use a GM 700R4 transmission instead of the original. I was young and naive and the 700R4 just made a lot of sense to me at the time. In retrospect (even before this problem) I wish I had gone ahead and had the original rebuilt or done it myself. So back to the problem of the body being too far to the rear. Somewhere in the instructions from Bendtsen’s or their website they mentioned that I may need to take a hammer to the body where the trans meets and the body meets but when we put the body in place a few years ago all the mount holes aligned so we assumed the hammering was not going to be necessary. Besides the instructions did not really say where exactly to hammer. It just said hammer for clearance. We would have had to place the body and find where it contacts the body then remove it, hammer it and then place it again. The image below (it was a tight fit) shows the very top of the conversation plate and the 700R4. They may not appear to be touching but they are. There is no way that body is going to move forward like it is now. When I first realized this I decided that a large rum drink was in order. I walked into the house, dejected and trying to figure out the lesser of two evils. Should I... Raise the body and beat the hell out of that spot so that it sits right or Remove the 700R4 and the conversation place and go with the original trans. Half way through my rum drink I remembered how I replaced the fuel pump in my old Chevy Squarebody truck a few years ago. I just cut a hole in the cab floor to gained access to the fuel pump without having to drop the fuel tank. It saved me days of work. So, now I am thinking maybe, at this point, my best bet is to simply cut a hole in the floor where the trans and the underside of the body meets to allow some clearance and move the whole body forward the inch or so that is needed. I can easily patch the hole again when everything is in place. What do you think about that idea? In the future I may go ahead and rebuild the original trans and mount it but that will be after the car is on the road and I have nothing else to do.

Posted on: 2021/9/21 16:24

|

|||

|

Stewart Ballard

|

||||

|

||||