|

Re: 1937 120 Center Dash Panel

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

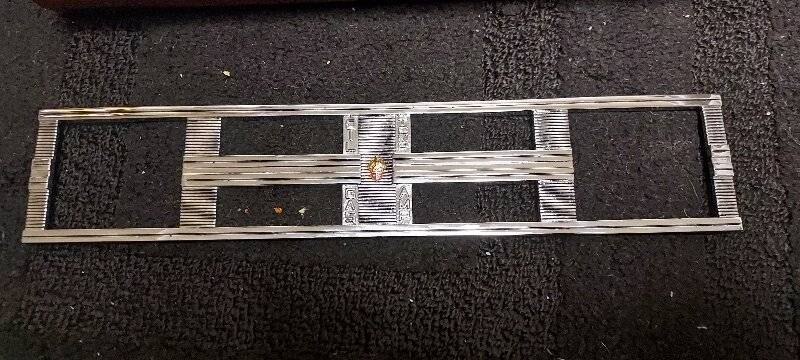

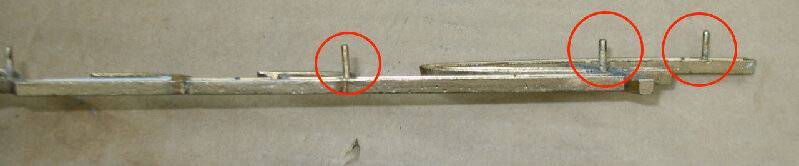

I don't have a car that old but I would almost bet that it originally had some studs on the chrome casting that went in the holes in the dash metal and the entire piece was held by speednuts that captured the studs. The back of the casting looks as if there might have been a broken off stud at each corner and in the middle right in the center of the protrusions at the circled spots. The holes in the dash look too small for a screw but not studs.

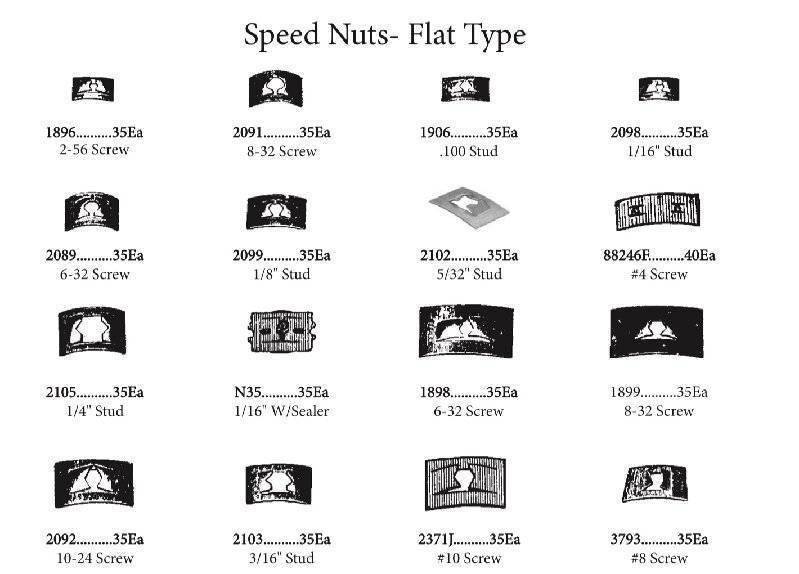

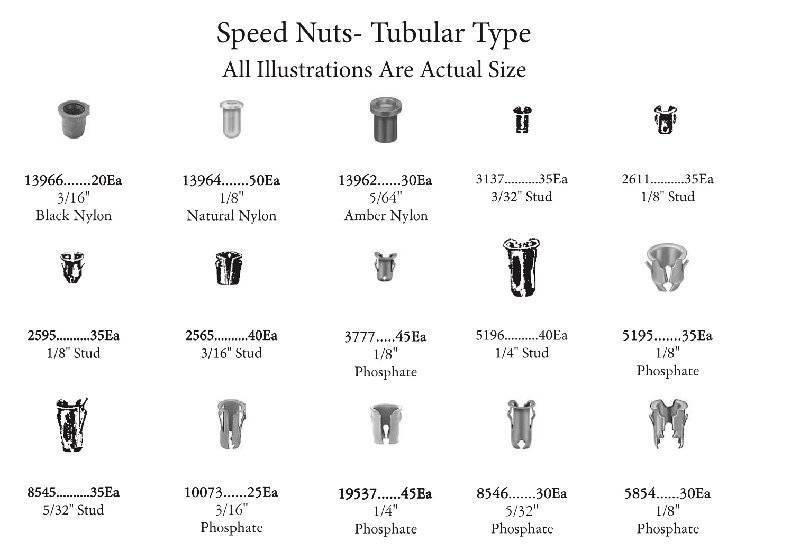

Packard used this attachment method on many other trim pieces, emblems and scripts. Many times, if someone is unaware of this configuration they try to pry the piece off and the studs break or pull off the casting in the process. The other photos show the rear of a script with the studs intact and a selection of typical speednuts. In addition to the flat nuts shown Packard also used round speednuts as well as push in tubular types that could have been inserted in the holes in the dash metal with the studs on the casting pushing into those. Attach file:  769_616e0dcf668ea.jpg (180.95 KB) 769_616e0dcf668ea.jpg (180.95 KB)  769_616e0d19c8303.jpg (175.49 KB) 769_616e0d19c8303.jpg (175.49 KB)  IMG_2502.jpeg (30.20 KB) IMG_2502.jpeg (30.20 KB)  speed nuts.jpg (90.85 KB) speed nuts.jpg (90.85 KB)  tubular speednut.jpg (83.69 KB) tubular speednut.jpg (83.69 KB)

Posted on: 2021/10/18 19:45

|

|||

|

Howard

|

||||

|

||||

|

Re: 1937 120 Center Dash Panel

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks Howard. Your wealth of knowledge never ceases to amaze me. We may have to rig up something as I don't see any studs in the collection of old hardware from disassembly. The next question is how to attach studs to the back of the cast bright work?

I found another photo on the internet from a restoration blog about 10 years ago. There is no protrusion in the back or evidence of speednuts. The holes on the corners and in the center appear to be flush with the metal dash with some sort of tacking. Hmmm..... Attach file:  1153_4f0506a971515.jpg (31.90 KB) 1153_4f0506a971515.jpg (31.90 KB)

Posted on: 2021/10/19 18:48

|

|||

|

||||

|

Re: 1937 120 Center Dash Panel

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

It is possible instead of studs they actually had small nubs that went thru the holes and was then peened over -- sort of like a rivet.

Probably no easy way to add studs or screws because there is no room for a blind threaded hole in the thin casting. Do the gauges and other items that go thru the casting have something in their mounting that would add some pressure to the casting and help keep it in place? If so I wonder if a high strength double sided trim or emblem tape such as used on modern cars could be placed on the back of the casting to stick the sides to the center panel without being so thick it would hold the casting noticeably away from the panel.

Posted on: 2021/10/19 19:24

|

|||

|

Howard

|

||||

|

||||

|

Re: 1937 120 Center Dash Panel

|

||||

|---|---|---|---|---|

|

Home away from home

|

two faced foam acrylic mounting tape may let you attach this. You'd need a thinner type than typically used for bodyside moldings. 3M supplies it industrially

Posted on: 2021/10/20 2:02

|

|||

|

||||

|

Re: 1937 120 Center Dash Panel

|

||||

|---|---|---|---|---|

|

Home away from home

|

I tapped mine with a #4/40 bottoming tap and screwed it on. You just have to be very careful that you don't poke through the front. That pot metal is soft so make sure you start nice and straight from the get go as well.

Posted on: 2021/10/20 12:29

|

|||

|

||||

|

Re: 1937 120 Center Dash Panel

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks Gents for your suggestions. We have a few options now to consider.

Posted on: 2021/10/20 12:46

|

|||

|

||||

|

Re: 1937 120 Center Dash Panel

|

||||

|---|---|---|---|---|

|

Home away from home

|

Just verifying the fact that the panels are held in by cast in studs that are peened over for assembly. I just disassembled my dash on my 37 Coupe Convertible 120 and that is evident on mine. Likely these broke/drilled out for removal for the plating process. I agree that the use of foam double sided tape or a series of small dabs of a urethane adhesive will be your best reassembly method.

Posted on: 2021/11/5 18:30

|

|||

|

||||

|

Re: 1937 120 Center Dash Panel

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

I would try a product called "Q-Bond", it is an ultra strong adhesive powder that you add a harderner to and is rock hard in 10 seconds.Just overlap it on the back side of the panel and the chrome center piece and no drilling needed. It is available at many auto parts stores and I'm sure online. I've used it in similair situations and was very pleased with it.

Posted on: 2021/11/6 18:54

|

|||

|

||||