|

Re: ‘56 400 vapor lock

|

||||

|---|---|---|---|---|

|

Home away from home

|

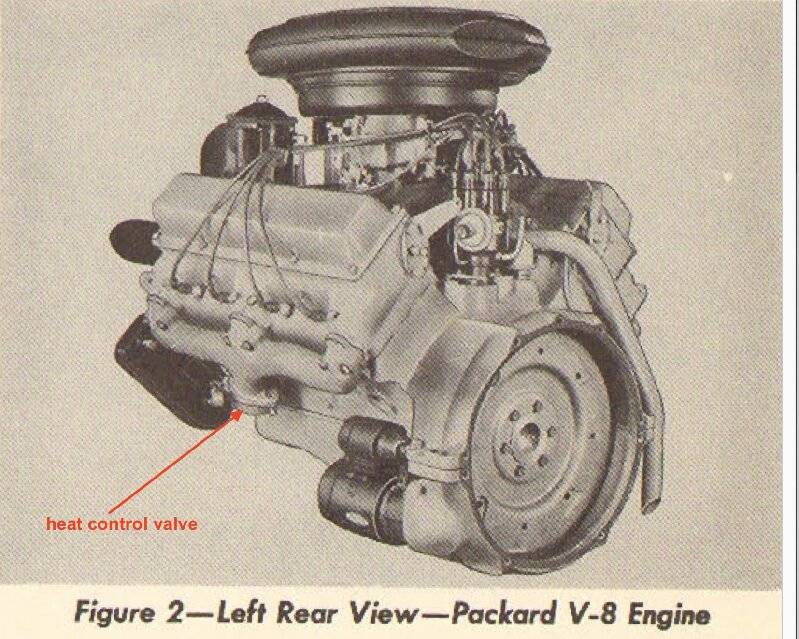

The thermostatic valve flapper on most V8 engines is at one of the exhaust manifolds were it connects to the tailpipe and I expect it's the same for Packard V8s.

Posted on: 2022/5/21 23:46

|

|||

|

||||

|

Re: ‘56 400 vapor lock

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Valve is sandwitched between the left manifold outlet and the exhaust pipe and held in position by the two screws attaching the exhaust pipe. The weight should be free to move and if it is up when engine is cold and hanging down when the engine is hot the valve is working.

A fiber spacer or heat shield was used on inline eights but is not used on the V8 engines because the hot manifold heat typical of the inline eights is off to the sides and is a fair distance away from the V8 carb. Modern gasoline is very volatile and prone to heat letting trapped bubbles expand and collect causing the issue. Several have found an electric fuel pump at the tank which can be controlled by an under dash switch and only used for priming after the engine has sat for several days or switched on when signs of vapor lock occur will help alleviate issues.

Posted on: 2022/5/22 0:12

|

|||

|

Howard

|

||||

|

||||

|

Re: ‘56 400 vapor lock

|

||||

|---|---|---|---|---|

|

Home away from home

|

I have a 1955 Clipper Custom, I live in Phoenix, Az. I experience vapor lock when the temperature is over 95F. There has been a lot of talk here on this website about vapor lock. Today's gas is to blame. All I know is that I use a mechanical fuel pump until I experience vapor lock and then I turn on my electric fuel pump. I am on my 2nd electric fuel pump. I have been driving my car for over 20 years and have put over 70,000 miles on it. I don't know everything, but I have experienced vapor lock. At over 110F, I will drive my Clipper, my wife will not be in the car, and the electric fuel pump is on. Good luck and get an electric fuel pump, put it by the gas tank. But continue to use the mechanical fuel pump.

I also use a Chrysler mechanical fuel pump, it isn't affected by today's fuel. Look in the Parts Cross-Reference and find it there.

Posted on: 2022/5/22 1:23

|

|||

|

1955 Clipper Custom

1940 160 Touring Sedan 1953 Patrician 1948 Super 8 Limo |

||||

|

||||

|

Re: ‘56 400 vapor lock

|

||||

|---|---|---|---|---|

|

Home away from home

|

I cut that valve out.

Have no warm up problem.. My. Problem is if its sits awhile after driving. Hard to start. Turn off to fill up not a problem. Which I think is carb related .. I think the all metal needle valves are better. And not made anymore.

Posted on: 2022/5/22 7:39

|

|||

|

Riki

|

||||

|

||||

|

Re: ‘56 400 vapor lock

|

||||

|---|---|---|---|---|

|

Just popping in

|

Thanks so much for the info. I’ll try to see if I can determine if the valve is working, or even if it is there at all. Do you know if this valve typically gets stuck, and how to keep it free and working? Maybe Max Merritt sells them?

Posted on: 2022/5/22 8:32

|

|||

|

||||

|

Re: ‘56 400 vapor lock

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

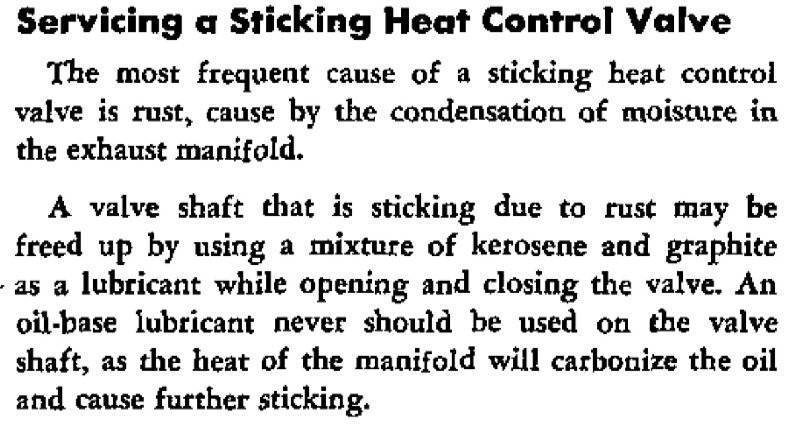

They do get stuck on occasion but if you are able to grasp the weight and rotate the flapper assy that part is OK. Do take care not to use a great amount of force and on the 55-6 assys I would avoid hitting the assy with a hammer. If the movement is stiff do not try to lube with ordinary petroleum products as oil or grease will degrade from the heat and make the problem worse. Here is a procedure Packard recommended to lube earlier valves. The valve layout is different but the principle will be the same. There may be a commercial product that is graphite based and will effectively be the same as the kerosene and graphite.

55-6 valves are contained in a small cast cylindrical assy that is held in position by casting flanges that fit into respective openings in the manifold and exhaust pipe. Those flanges along with gaskets and the exhaust pipe attaching bolts that fit in sort of semicircular depressions in the cast assy provide a solid leak proof section. Aftermarket replacements from a parts store that fit the Packard manifold and mounting method have proven hard to find but NOS are still available from some of our vendors at a significantly higher price. The original assy valve position flanges are prone to cracking or breaking off so do be gentle with the assy so as not to do damage. If enough flange is broken it will no longer stay in position and vibration can move it enough the missing flange parts will provide a good spot for an exhaust leak.

Posted on: 2022/5/22 10:40

|

|||

|

Howard

|

||||

|

||||

|

Re: ‘56 400 vapor lock

|

||||

|---|---|---|---|---|

|

Home away from home

|

On earlier cars they were part of the manifold so difficult to free up or replace but by the V8 models it was separate so if stuck or otherwise not working, it could be replaced. Yes, check it and if stuck try Max Merritt or one of the other dealers.

Posted on: 2022/5/22 10:41

|

|||

|

||||

|

Re: ‘56 400 vapor lock

|

||||

|---|---|---|---|---|

|

Just popping in

|

Checked the flapper valve on the exhaust manifold - it appears to be working properly. I replaced the electric fuel pump (it did have one, but it was dead) and no more vapor lock! But - and I wish I was making this up - on my test drive to put the vapor lock issue to bed, on my return home my drivers side rear electric window decided to stop working! Well, at least I can drive the car. Thanks again for the help. If I get stuck with the rear window on my ‘56 400 you’ll be hearing from me again…

Posted on: 2022/5/22 17:42

|

|||

|

||||

|

Re: ‘56 400 vapor lock

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

on my return home my drivers side rear electric window decided to stop working! Well, at least I can drive the car. Thanks again for the help. If I get stuck with the rear window on my ‘56 400 you’ll be hearing from me again… All the windows are powered from the same relay and source so unless you have a broken wire going to the failed door and only that switch does not operate the motor it is not likely a power supply issue. Switches and motors are both a known failure item. If power is present and a single switch does not work the window then the switch is likely. There is also a possibility the push on connector that connects to the switch connecting pins has a loose terminal inside or has become disconnected from the back of the switch. The usual switch failure is due to a very small surface on one side of a rivet that makes the contact inside the switch. That small surface carries a large amount of current and frequently arcs and otherwise gets hot enough to melt the copper rivet end flush with the moving support surface of the switch so rivet can no longer make contact. A switch failure usually happens in one direction only. If both the drivers door and rear window switches fail to operate then most likely the motor. The usual motor failure is a broken armature shaft but if you hear noise like the motor is trying to work then a mechanical issue with the regulator or something blocking a window channel cannot be ruled out. The original motors have a thermal breaker inside them. If there is a large amount of drag on the window and motor was overloaded there is also a possibility that breaker tripped but those will reset when motor cools.

Posted on: 2022/5/22 18:24

|

|||

|

Howard

|

||||

|

||||

exhaust manifold heat control valve.jpg (293.52 KB)

exhaust manifold heat control valve.jpg (293.52 KB)