|

Re: 1931 Intake and Exhaust valve/valve guide clearances?

|

||||

|---|---|---|---|---|

|

Home away from home

|

I looked in the parts listing for intake/exhaust valves and saw different parts numbers for the 826/833 and the 840/845 engines. That leads me to believe that heftier valves were used for the larger engines. Perhaps what Kanter/Max provided you were valves for the standard 8. I'd suggest you get on the horn with them and see if they supplied you with the right part. Seems a tad too small.

Posted on: 2022/7/22 10:06

|

|||

|

||||

|

Re: 1931 Intake and Exhaust valve/valve guide clearances?

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Turns out that the valves from Max Merritt and Kanter are supplied by Egge- my mechanic spoke with Egge and they only use a .340 inch stem blanks and don’t have access to a thicker stem blank. Our current thoughts are that we will reuse the exhaust valves after cleaning them up, and then we’ll probably use the thinner .340 intake valves. Since the 3 intake valve in cylinders 2, 4 and 6 were sticking, perhaps having more clearance won’t be a bad thing. Also, since the valves are only splash lubricated- not under oil pressure, I don’t think we’ll be burning through lots of oil with the larger valve/guide clearance. Thoughts?

Posted on: 2022/7/22 11:00

|

|||

|

||||

|

Re: 1931 Intake and Exhaust valve/valve guide clearances?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I can't speak specifically to your 840 but stem to guide clearance specifications for L-head engines are typically 0.002" for intake and 0.004" for exhaust. At least in later years the guides were all reamed to the same dimension and the different clearances were obtained by different stem diameters.

Several reasons to avoid excessive clearances, one of which is battering of the seats.

Posted on: 2022/7/22 11:42

|

|||

|

||||

|

Re: 1931 Intake and Exhaust valve/valve guide clearances?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Can you install custom fit guides to fit the slender stems? How challenging would that be?

Posted on: 2022/7/22 17:52

|

|||

|

||||

|

Re: 1931 Intake and Exhaust valve/valve guide clearances?

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

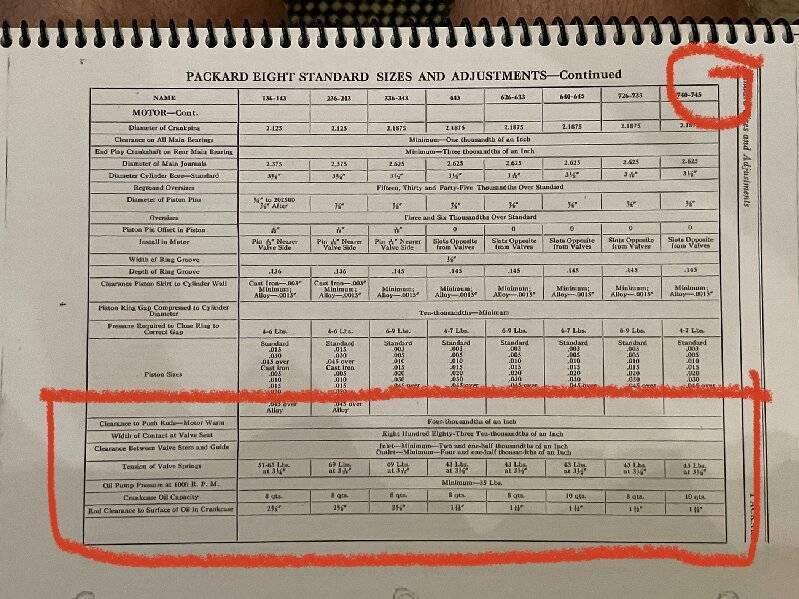

I finally found official documentation of the valve stem/guide clearance! I ordered the 1931 Service letters from the Packard club (1931, Volume 5, No. 1-24) and it included an extensive table of specs- Packard Eight Standard Sizes and Adjustments. See the attached photo, it includes data from 1st-7th series. I’m pretty sure the 8th series is not much changed from the 7th series. INTAKE minimum .0025”, EXHAUST minimum .0045”.

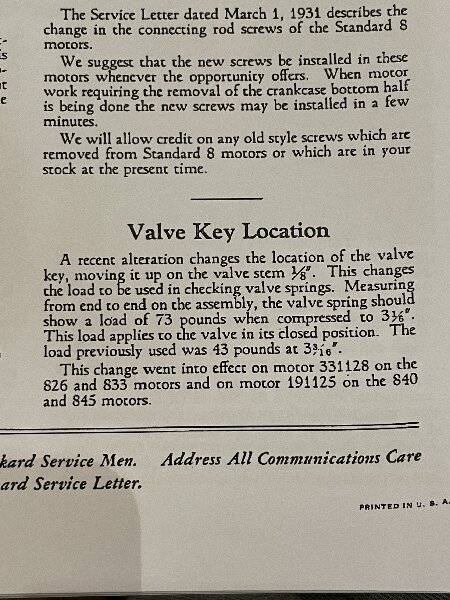

Also, we noticed that the valve keeper/key slot in the stem of the new valves from Max Merritt and Kanter did not match the original Packard valves from my engine. It turns out that the moved the valve keeper/key slot 1/8” up the stem to increase the spring tension. This change began with engine number 191125 for the 840- my engine number is 189598, so it make sense that my original Packard valves have a different valve key/keeper slot location. I wonder if they made this change in response to valves sticking, to increase the spring load to help close the valves (43 lbs with old, and 73 lbs with new) @Greenfield- yes, we can get matching guides for the .340 new valves, but I’m not keen on removing the cylinder block to remove old guides and press in new ones. Apparently this can possibly be done without removing the block, but my mechanic is wary. Attach file:  33AFB9C5-D451-4A73-8FBA-D8BF15EBE5AF.jpeg (324.15 KB) 33AFB9C5-D451-4A73-8FBA-D8BF15EBE5AF.jpeg (324.15 KB)  7AA10C61-E74F-4628-B003-BD33FF1A5D8D.jpeg (297.30 KB) 7AA10C61-E74F-4628-B003-BD33FF1A5D8D.jpeg (297.30 KB)

Posted on: 2022/7/24 15:01

|

|||

|

||||

|

Re: 1931 Intake and Exhaust valve/valve guide clearances?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Metal spray technology or HVAF is commonly used to build up worn surfaces, crank journals, cam journals, valve stems, etc.

In most cases the HVAF coating is superior to the base metal, better wear properties / less friction. This would be one option if you wanted to build up the stem to have the correct stem to guide clearance. kermetico.com/applications/hvaf-thermal- ... wear-resistant-coatings-valve-stems

Posted on: 2022/7/27 17:20

|

|||

|

||||

|

Re: 1931 Intake and Exhaust valve/valve guide clearances?

|

||||

|---|---|---|---|---|

|

Home away from home

|

You don't have to remove the block to replace valve guides. You can drive them down part way, grind a slot part way, and break off the exposed section with a hammer. Then continue until the guide is out.

In a hurry you don't have to do the slot grinding and just knock the half off, but it is wreckless. If you are planning on the brass insert route then I suppose you have to send the block out so that it can be set up in a mill. Either way the seats will need to be ground, topped, and throated; and then checked for concentricity.

Posted on: 2022/7/27 21:40

|

|||

|

||||