|

Re: Rebuilding distributor

|

||||

|---|---|---|---|---|

|

Home away from home

|

Replacing bushes is not difficult if you have a way to size them after installation, which usually involves reaming. You'd be working with some delicate parts, and wear in things like piovot pins may not be easy to assess. Small springs in the centrifugal advance can stretch or lose tension. If the shaft is very loose, replacing the bushes would no doubt make a significant improvement.

A new shaft, bushes, and springs would be nice, if they can be had.

Posted on: 2023/6/14 12:38

|

|||

|

||||

|

Re: Rebuilding distributor

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Good point about potentially needing to ream the bushing. I would think the clearance should be quite low like 1-2 thousands.

Posted on: 2023/6/14 13:02

|

|||

|

||||

|

Re: Rebuilding distributor

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Two thousandths clearance on a distributor bushing fit is excessive, I suggest less than half of that as a maximum, and preferably about 0.0005".

Posted on: 2023/6/14 14:27

|

|||

|

||||

|

Re: Rebuilding distributor

|

||||

|---|---|---|---|---|

|

Home away from home

|

This used to be local parts store stuff, but they haven't sold for decades, since electronics. (pet peeve)

If the cam & drive gears in good shape, shaft OK, I think you can still buy Delco dist. bushing(s)/shims, try Brillman. Not sure about the other parts, they may have too. We're somewhat spoiled by reliability of modern conveniences and progress when dealing with these old cars. These were "oiled" though a side arm cup, so the oil has to flow/seep into the bushing space, can't be too tight. When you see those little snap caps on the end, they're for oil. Every household had oil cans about, but rarer today. If grease is in it, something is wrong and maybe why it failed or wasn't lubed/incorrect. Oilite bushings are porous and made/come impregnated with oil. There are several distributor rebuilders around, I'd contact one of those to see what they can do. They deal with this all the time. Without the machine and the right specs/ parts, you'd be taking a chance of failure DIY, if it's wobbling much, not running good. If it's been running OK, U R just curious/want to learn, then maybe not so much an issue here. They don't wear to much if maintained. But U did not state that info, only asked how to? Sounds like the (growing) lack of knowledge with points vehicles. Condensers are usually just changed with points not tested.(Capacitance tester req'd.) Inexpensive item and somewhat fragile material under charge.

Posted on: 2023/6/15 11:06

|

|||

|

||||

|

Re: Rebuilding distributor

|

||||

|---|---|---|---|---|

|

Home away from home

|

FJ offers some good information on these distributors. Some of them used a grease cup on the side of the body to lubricate the bushing and shaft. Many people do not understand what these are and how to service them. This inattention can lead to wear on the bushing and shaft.

Posted on: 2023/6/15 11:26

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

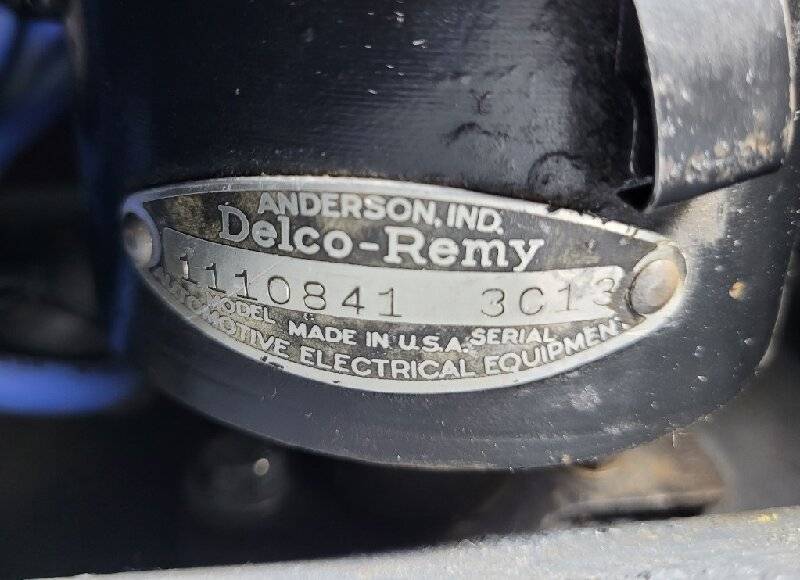

Distributor.jpg (71.08 KB)

Distributor.jpg (71.08 KB)