|

Re: Water distribution Tube - 1948 - 356

|

||||

|---|---|---|---|---|

|

Home away from home

|

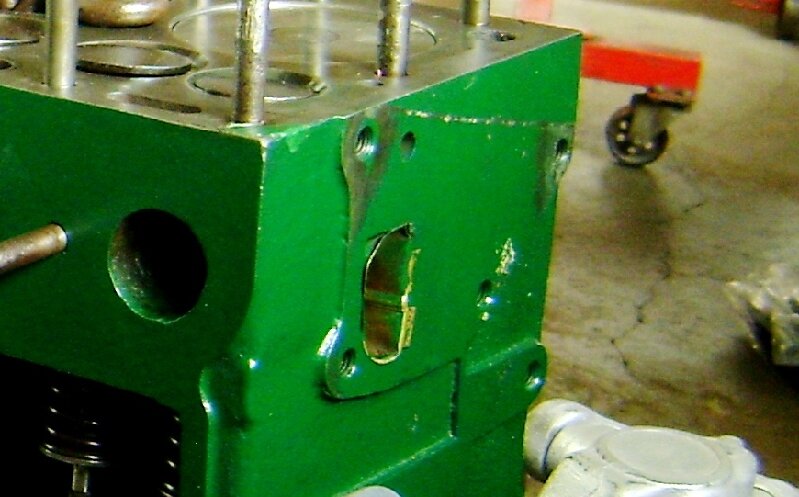

It pulls out the front once the water pump and radiator have been removed. The service manual shows a tool being used but probably a steel coat hanger or other stiff wire with a small tight hook bent at. The end will suffice.

Posted on: 2023/12/17 3:03

|

|||

|

All generalities are false.

Once I thought I was wrong but I was mistaken. Don Pierson Packard / IMPERIAL page CA DMV Licensed Vehicle VIN Verification 1951 Henney-Packard 3-Door Long Wheelbase Air Force Ambulance The 1951 Henney-Packard is For Sale! 1954 Packard Patrician 1954 Packard Patrician Parts Car 1956 Clipper Custom Sedan |

||||

|

||||

|

Re: Water distribution Tube - 1948 - 356

|

||||

|---|---|---|---|---|

|

Home away from home

|

Agreed, I removed mine just like that, bent a coat hanger wire in an 'L' to fit into the hole drilled in the top of the front area of the tube, chucked it in a slide hammer and it slid right out. Mine had sat for 60 years with an empty water jacket having had the frost plugs knocked out and was still shiny brass with the usual mouse house inside. Well made part and cleaned up great.

Bob J.

Posted on: 2023/12/17 9:06

|

|||

|

||||

|

Re: Water distribution Tube - 1948 - 356

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Keep your fingers crossed it pulls out smoothly and be thankful you have a brass tube and it is still in decent condition to pull out. Those who happen to have a car where the original brass tube was replaced with one of the sheetmetal aftermarket or replacement tubes that were apparently around during or shortly after the war will have some fun. The steel tubes are often found to be very rusted and if there is enough remaining in any condition to come out will probably come out in small pieces.

Posted on: 2023/12/17 10:22

|

|||

|

Howard

|

||||

|

||||

|

Re: Water distribution Tube - 1948 - 356

|

||||

|---|---|---|---|---|

|

Home away from home

|

I was not aware, good point.

I guess they call it progress, but it has gone on too long!! Bob J.

Posted on: 2023/12/17 14:56

|

|||

|

||||

|

Re: Water distribution Tube - 1948 - 356

|

||||

|---|---|---|---|---|

|

Home away from home

|

I think as you planned, flushing it more thoroughly, drain well, and new coolant it should be OK til you get it rebuilt. I got all kinds of crud out of the '49 and it ran just fine(cool) when I had it running.

When there's dissimilar metals in a system they are subject to more corrosion. Brass is more "noble" so lasts better in aqueous systems. Cast is better than mild sheet steel. A periodic extra dose of coolant inhibitor is usually called for with mixed systems but Prestone claims/warrants it's not necessary with their silicate based inhibitors... Frequent flushing and changing is the best maintenance protocol, usually every ~4 years or so, about 50K miles. These old systems have more lead based solder in them and heavier gauge brass. The solder is the weak link usually, tends to pinhole/ pitting corrosion.

Posted on: 2023/12/19 13:14

|

|||

|

||||

water distribution tube-in place.JPG (215.94 KB)

water distribution tube-in place.JPG (215.94 KB)