|

Re: 352 onto an engine stand

|

||||

|---|---|---|---|---|

|

Home away from home

|

That worked quite OK for me the last twenty or so times I did it. Of course you'll want to choose your bolts carefully to get good engagement.

Posted on: 2024/6/14 20:15

|

|||

|

||||

|

Re: 352 onto an engine stand

|

||||

|---|---|---|---|---|

|

Home away from home

|

I have my 320 mounted like that now. Just use some common sense: select the longest bolts that don't bottom out. On my stand I think these were 3½ inch bolts. Factory length is 1⅜; subtract the transmission flange thickness to get the correct depth.

To rip a Grade 8 7/16 bolt out takes something like 10,000 lbs of force.

Posted on: 2024/6/14 20:31

|

|||

|

1955 400 | Registry | Project Blog

1955 Clipper Deluxe | Registry | Project Blog 1955 Clipper Super Panama | Registry Email (Parts/service inquiries only, please. Post all questions on the forum.) service@ultramatic.info |

||||

|

||||

|

Re: 352 onto an engine stand

|

||||

|---|---|---|---|---|

|

Just popping in

|

Thanks for the replies, I realise the bolts are solid but I was a little worried about the thickness of that trans flange!

That engine is a rare as rocking horse poop over here 🤣

Posted on: 2024/6/15 1:20

|

|||

|

||||

|

Re: 352 onto an engine stand

|

||||

|---|---|---|---|---|

|

Home away from home

|

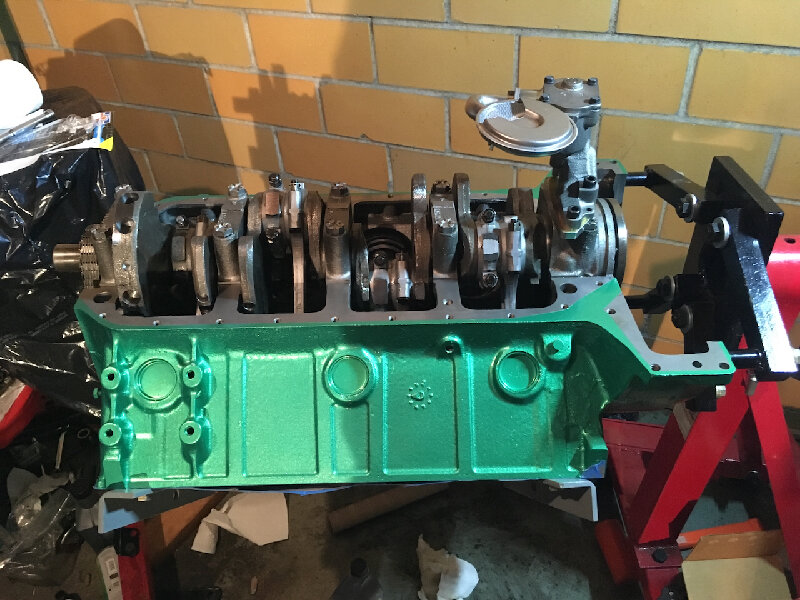

My 352 on a stand. I did use grade 8 hardware.

Posted on: 2024/6/15 4:18

|

|||

|

||||

|

Re: 352 onto an engine stand

|

||||

|---|---|---|---|---|

|

Home away from home

|

Grade 8 bolts are overkill. The standard grade 5 is more than sufficient.

What I do differently is turn the engine stand arms around so the back of the block is against the arm and not held further out by the spacer. Also, adjust the arms up and in so the cam is centered on the pivot point. This will make it more balanced when the heads are installed. jack vines

Posted on: 2024/6/15 10:31

|

|||

|

||||

|

Re: 352 onto an engine stand

|

||||

|---|---|---|---|---|

|

Just popping in

|

Thanks Jack ! Exactly the detail I was after and of course makes perfect sense, now off to find some bolts 😀.

Posted on: 2024/6/15 15:00

|

|||

|

||||

IMG_6516.jpeg (394.54 KB)

IMG_6516.jpeg (394.54 KB)